1 / 5

Plastic Banbury Mixer for PP Pellets

| Model No. : | LN-KP-0.5 |

|---|---|

| Brand Name : | LINA |

| Raw Material : | EVA |

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Product description

LINA 0.5L PP Mixing Pelletizing Production Line

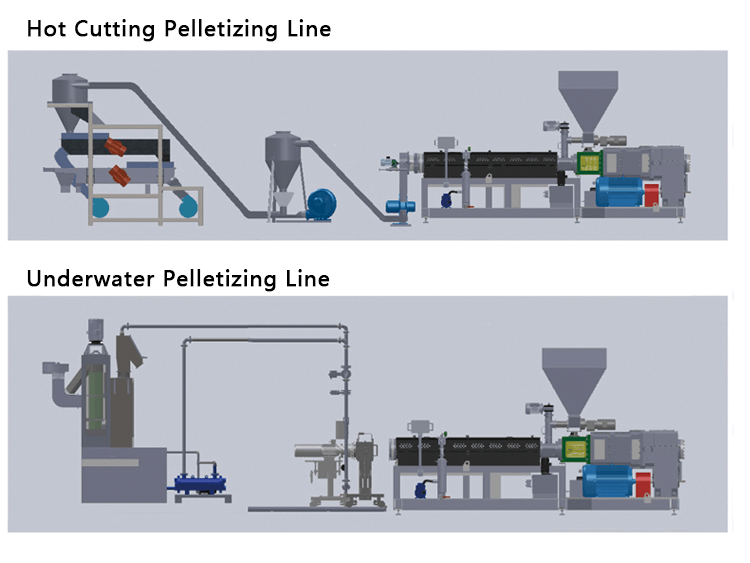

LINA Plastic Internal Mixer for PP/PE/PET/PVC with automatic pelletizing system is specially designed for laboratory test, R&D and middle size production. LINA Multi-Functional Pelletizing Line for rubber and plastic truly achieve "more than one machine" on one independent operation platform that is, intelligent, modular, environmental protection and energy-saving. The innovation points of LINA Laboratory Granulation Production Line are that it is able to use screw or hydraulic method to extrude the material in the dispersion kneader to granulation process. The entire working process is continuous and modular. LINA Lab Pelletizing Production Line is specialized for different rubber and plastic compounds with various physical characteristics, and die surface hot cutting & air cooling is its main pelletizing method. LINA Automatic PP Laboratory Granulation Production Line centralizes the function of Plastic Dispersion Kneader and Plastic Granulator on one independent operation platform. This machine is kneading and pelletizing integrated and its continuous mixing and granulation process is 1-2 times more efficient than traditional Rubber and Plastic Particles Production Line.

Characteristics of LINA Plastic Mixing Pelletizing Machines

1. Automation: Continuous kneading and pelletizing2. Eco-friendly: No gas masks needed while operating

3. User-friendly: Quick release design for die head

4. Modular: Based on user's demand, manually material feeding can be updated to automatic weighted feeding

Advantages of LINA Plastic Dispersion Kneader with Pelletizing Functions(Main techniques and drawings are from Taiwan, Japan and so on.)

1. The unit has the whole unit process chain, sound and light failure alarm and fast lock fault point and other control functions. All parts that are in contact with the material are made of stainless steel.2. High accuracy of temperature control system to ensure the temperature sensitivity of the material.

3. It adopts the drop type separating method after cutting process, to avoid Particle agglomeration and ensure particle cooling.

4. Feeding system of the pressing machine adopts heater and reversing device to solve problem of power outage, material crash and cleaning.

5. Especially, the barrel and die head adopts advanced foreign techniques to ensure and control the dangerous occurred when the pressure is uncontrollable. The honeycomb filter plate is easy to clean and quickly change the mesh and the die head t easy to leak.

6. The hoist adopts automatic return technology to ensure the working efficiency.

7. The technological combination of dual-pull forced feeder and single screw not only meet the high requirement of secondary continuous mixing, but also solve the problem of time and power consuming of traditional working process.

LINA After-Sales Services

1. On-site installation assistance is available. (There are no charges on installation and trial running, but VISA fees, accommodation fees and transportation fees etc, of the supplier's side are charged by the buyer.)

2. Training of customer's operators and maintenance personnel and long-term technical consultation is provided.

3. One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/components are available. During the warranty period, the supplier, within three hours since receipt of purchaser's notice of any equipment fault, shall provide express solution, and, if necessary, assign service engineer(s) to site across China within 72 hours or site in Pearl River Delta within 5 hours (excluding travel time). Response time for customers overseas shall be agreed upon otherwise based on application for visa and accessibility to the customer's location.

Are you factory or trading company?

LINA Machinery has been engaged in Rubber & Plastic mixing machine for many years. We have workshop and R&D department.

What about the operational guideline?

Training of customer's operator and maintenance personnel and long-term technical consultation is provided.

How about the warranty time?

One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/component are available.

Do you offer the customization of the machine?

Certainly, LINA will give you the most proper recommendation and setting according to your

materials and demand.

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Send your inquiry to this supplier