1 / 1

Plasma Gantry cnc flame cutting machine for metal

| Model No. : | KR-PL Series |

|---|---|

| Brand Name : | KASRY |

Product description

Brief introduction

The gantry CNC plasma and flame cutting machine is specially designed for metal plate cutting,it is characterized of high automation and efficiency,easy operation and long service time. This CNC plasma and flame cutting machine is gantry structure with double-driven system, working size can be customized upon requirement.It can be used for cutting carbon steel, stainless steel and non-ferrous metal in any 2 d graphics,thus is widely used in metal cutting fields.

Features

1. Steel hollow beam design ensures good heat dissipation without deformation.

2. The gear-rack driving motions without engagement gap ensure the machine running smooth at high speed.

3. Fully functionalized CNC system and optocoupler device enhance the super anti-jamming capability of the plasma system.

4. World`s top branded components and circuits ensure long service life.

5. Multiple cutting torches can be configured. Both flame and plasma torches are optional to meet the needs of cutting different materials in a range of thickness.

Technical parameters

|

Cutting Area |

(2500- 7500mm) by (4000mm-20000mm)or customized |

|

|

Input Power |

220 ± 10%V AC 50Hz /60 Hz For Servo Motors: 1400 W For Step Motors: 500 W |

|

|

Cutting Modes |

Plasma Cutting / Flame Cutting / Plasma Cutting+ Flame Cutting |

|

|

Transmission Style |

Rack & Gear |

|

|

Drive Style |

Servo Motors Double Sides Drive Step Motors Double Sides Drive |

|

|

Torch Lift Distance |

200 MM |

|

|

Torch & Number |

One Plasma Torch / One Flame Torch / One Plasma Torch + One Flame Torch |

Two Flame Torches/One Plasma Torch+One Flame Torch |

|

Plasma Cutting Thickness |

Depend On Plasma source |

|

|

FlameCutting Thickness |

Piercing Cutting: 5-80 mm Edge Start: 5-150 mm |

|

|

Torch height control |

Plasma Automatic Torch Height Control / Flame Capacitance Torch Height Control |

|

|

Cutting Speed |

For Servo Motors: 0-10000 mm / min For Step Motors: 0-4000 mm / min |

|

|

Cutting Table |

Normal Cutting Table /work piece collect drawer cutting table / smoke and dust collector with work piece collect drawer cutting table.(We can supply drawing of the cutting table with the machine for free.) |

|

|

Positioning Accuracy |

≤±0.2mm /m |

|

|

Repeatability |

≤±0.3mm /m |

|

Accessories Show

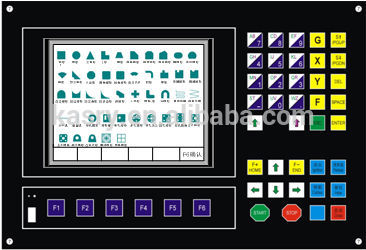

| CNC control system(China) |

|

Complete function, stable performance, can be slotted compensation of workpiece |

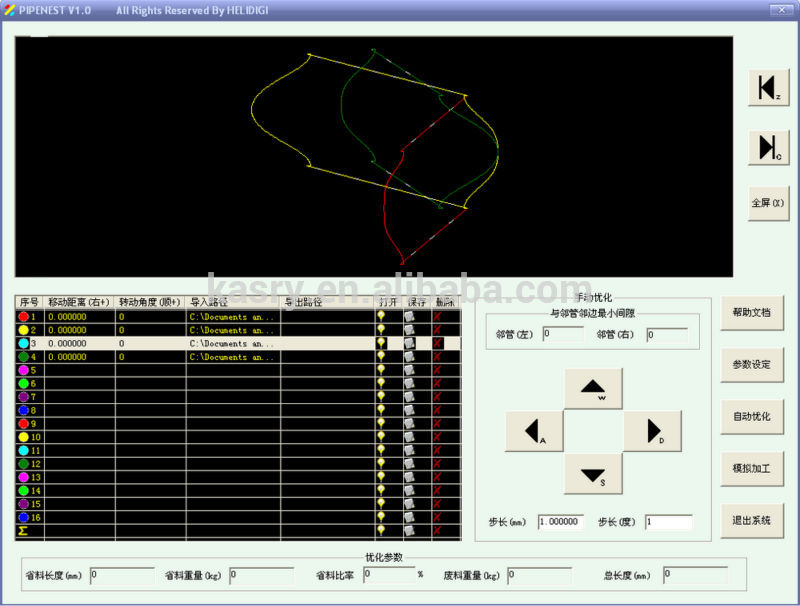

| Automatic programming nesting software(America |

|

Kerf compensation, plasma bridge, even the cut edge of the flame, sharp handling, CAD sub-layer cutting, text annotation functions |

| Driving system(Japan) |

|

Precise speed control, torque-speed characteristics hard, the principle is simple, easy to use, the price advantag |

| Reducer(Germany) |

|

Compact, high reliability, high performance data structure, light weight |

| Solenoid vale(Taiwan) |

|

High temperature stability, good closure |

| Imported Cable(Germany) |

|

long life |

Application

This machine can cut mild steel with flame cutting, and cut high carbon steel, stainless steel,aluminum, copper and other non-ferrous metal with Plasma cutting; can configurate as you required.,thus it is widely applied in industries such as machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotive etc.

After-sales service

1.One year warranty,free maintenance throughout service time..

2.free technical support through Email ,chatonline tools ,teamviewer and telephone.

3.Training and installation on-site if required.

Why choose us

1. Canadian Professional Pipe optimize CNC system has , AutoCAD version of the project design can be directly generated CNC machine code . Dimensional simulation operation, the node is expanded , long tube splitting , fittings optimization , oversized EGES DXF SAT and STL and other software compatibility

2 A user-friendly design , casting parts precision machining equipment to ensure high-precision, high stability , high life expectancy .

3. One year warranty,free maintenance throughout service time.

Send your inquiry to this supplier