1 / 1

Overmold for Electronics

| Model No. : | M160123 |

|---|---|

| Brand Name : | 3K MOLD |

| Shaping Mode : | Injection Mould |

Product description

At 3K MOLD, we have the experience to guide you through all the critical elements of overmolding from part and mold design to material selection.

If you want to improve your Product with Overmolding, please contact us today.

Overmolding is the process in which one thermoplastic material is molded onto a second material to produce a single part. The injection overmolding process is done by employing two separate molds that will bond two different materials to form a part with aesthetics and functional appeal.

The benefits of overmolding:

Cost and Time: Overmolding eliminates secondary operations, assembly, extra material and labor.

Design: Overmolding allows for more flexibility in design opportunities.

Materials : Wide ranges of hard and soft thermoplastic materials can be overmolded in an array of textures.

Lifespan of Product: Overmolding is a good option for parts that may need to be waterproof, airtight or more resistant to shock and vibrations.

Safety: Overmolding improves gripping areas, more shock resistant, and eliminates rough edges for more comfort and ease of use.

Aesthetics: Overmolding offers more pleasing shapes with more style and color choices.

| Project Information | ||

| Product Description | Part Name | Overmold for Electronics |

| Part Material | PP GF30 | |

| Part Size(mm) | 163.6*75*33 | |

| Mould Description | Cavity Insert Material | 1.2343(HRC48-52) |

| Core Insert Material | 1.2343(HRC48-52) | |

| Slider Insert Material | 1.2343(HRC48-52) | |

| Mould Cavities | 1+1+1+1 | |

| Mold parts Standard | Hasco | |

| Mould Life Time (Shots) | 1,000,000 | |

| Mould Type | Export to Germany | |

| Runner Description | Cold runner | |

| Injection Gate Type | Sub gate | |

| Ejection System | Ejector Pin | |

| Slide Qty. | 8 | |

| Lifter Qty. | 0 | |

| Injection moulding machine | 300T |

High quality mold starts with a high quality design.

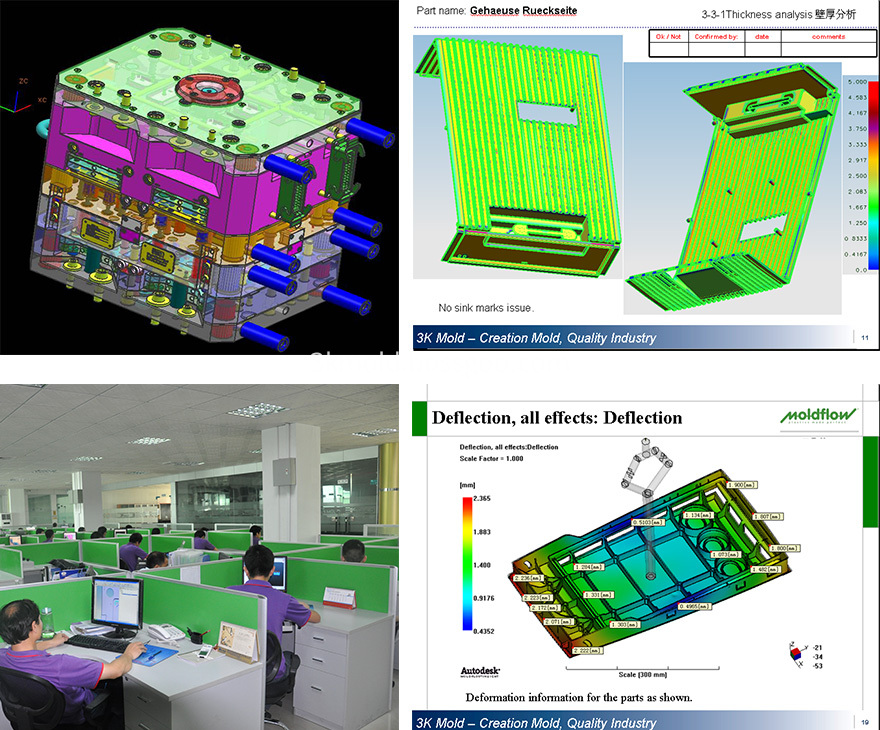

Before mold machining, Engineering will provide a DFM report to analysis potential issue such as injection gate type and position, Mold layout, Ejector pins layout, draft analysis, thickness analysis, part warpage, sink marks and surface finish etc. If necessary, We also provide the mold flow analysis report to analysis the filing, pressure, weld line, airtrap, deflection etc. To discuss with customer and determine the final mold concept. After providing the 3D/2D for final approval.

At 3K Mold Group, our design team consists of 15 skilled designers. They knew Hasco, DME and Custom standard etc Europe andAmericamold standard very well. Equipped with the latest hardware and software CAD, CAE,CAMto assist mold design and manufacturing. Rely on advanced equipment and 20 years experience in mold industry. 3K Mold Group has been built a diversified customer base from different industry.

Send your inquiry to this supplier