1 / 4

Oil Impregnated capacitor type bushing

| Brand Name : | TBEA |

|---|

Product description

for 252kV to 1700kV, advanced wholly automatic imported rewinding machine

Product Description Oil impregnated capacitor type bushing A: Computer is used to carry out optimal design for bushings, and the internationally advanced INFOLYTICA computing software is adopted to carry out the calculation analysis of electricity distribution inside and outside the bushing and choose appropriate technical parameters to ensure small partial discharge, high electrical insulation level, and long term function reliability. B: As for 252kV to 1700kV, advanced wholly automatic imported rewinding machine is used for insulation rewinding process, in which drying process is also finished at the same time. As for 72.5kV and 126kV, internationally leading coal oil-vacuum phase drying system is adopted to the drying of capacitance core to ensure excellent drying performance and low dielectric loss factor.

Oil-impregnated Paper Capacitor Type Bushing Product Specification

Oil-impregnated Paper Capacitor Type Bushing Product Specification Highest voltage for equipment | Um | kv | 24 | 40.5 | 72.5 | 126 | 252 | 363 | 420 | 550 | 800 | 1100 |

Maximum line voltage |

| kv | 14 | 23 | 42 | 73 | 145 | 210 | 242 | 318 | 462 | 635 |

Partial discharge |

| Pc | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

Power frequency withstand voltage test |

| kv | 55 | 95 | 155 | 255 | 505 | 625 | 695 | 750 | 970 | 1200 |

Lighting impulse voltage (full wave) |

| kv | 125 | 200 | 325 | 550 | 1050 | 1175 | 1425 | 1675 | 2100 | 2400 |

Lighting impulse voltage (chopped wave) |

| kv | - | - | - | - | 850 | 950 | 1050 | 1175 | 1550 | 1950 |

Switching impulse voltage |

| kv | 138 | 220 | 358 | 605 | 1150 | 1293 | 1568 | 1843 | 2310 | 2760 |

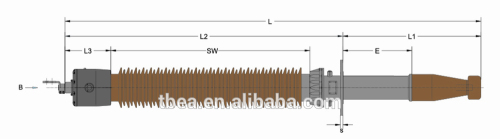

Minimum flashover (dry arc) distance | SW | mm | 335 | 450 | 720 | 1150 | 2330 | 3720 | 3850 | 4925 | 6435 | 9585 |

Creepage distance |

| mm | 840 | 1418 | 2550 | 3906 | 8595 | 13800 | 14000 | 18755 | 22850 | 35600 |

Creepage coefficient |

| 1/s | 2.5 | 3.2 | 3.5 | 3.4 | 3.7 | 3.7 | 3.6 | 3.8 | 3.6 | 3.7 |

Bending withstand load |

| N | 3150 | 4000 | 1000 | 1250 | 4000 | 4000 | 5000 | 4000 | 5000 | 5000 |

Relative voltage creepage distance (nominal) |

| mm/kv | 35 | 35 | 35.2 | 31 | 34.1 | 38 | 33.3 | 34.1 | 28.6 | 32.4 |

Size specification | D1 | mm | 325 | 550 | 280 | 350 | 500 | 600 | 430 | 660 | 711 | 930 |

| D2 | mm | 360 | 600 | 310 | 400 | 550 | 650 | 480 | 710 | 780 | 1000 |

| S | mm | 15 | 25 | 18 | 18 | 25 | 30 | 25 | 25 | 35 | 35 |

| i | mm | 20 | 20 | 18 | 24 | 24 | 24 | 20 | 24 | 32 | 32 |

| z |

| 8 | 12 | 6 | 6 | 12 | 16 | 8 | 16 | 12 | 20 |

| a | ° | 22.5 | 15 | 30 | 30 | 15 | 11.25 | 22.5 | 11.25 | 15 | 9 |

| E | mm |

|

| 425 | 410 | 760 | 500 | 500 | 550 | 600 | 505 |

| L1 | mm | 386 | 415 | 685 | 810 | 1880 | 1670 | 1335 | 2070 | 1955 | 2735 |

| L2 | mm | 420 | 602 | 1170 | 1600 | 3110 | 4680 | 4770 | 5945 | 7556 | 11155 |

| L3 | mm | 15 | 32 | 315 | 315 | 450 | 580 | 540 | 585 | 661 | 970 |

| L | mm | 806 | 1017 | 1855 | 2410 | 4990 | 6350 | 6105 | 8015 | 9611 | 13890 |

Equipment introduction The company is well equipped with advanced testing and manufacturing facilities: an imported fully automatic rewinding center, an imported kerosene vapor phase drying equipment, an imported RIP bushing vacuum drying&casting equipment, a world only 1000kV OIP&RIP bushing fully automatic rewinding machine, and a 1200kV series resonance reactor and a 3600kV impulse voltage generator in the testing hall which has high quality shielding materials that guarantee the background Partial Discharge in the test hall is less than 2pC. The first class hardware facilities, perfect testing method, good testing environment and powerful production capacity guarantee the stability and excellence of our products.

Equipment introduction The company is well equipped with advanced testing and manufacturing facilities: an imported fully automatic rewinding center, an imported kerosene vapor phase drying equipment, an imported RIP bushing vacuum drying&casting equipment, a world only 1000kV OIP&RIP bushing fully automatic rewinding machine, and a 1200kV series resonance reactor and a 3600kV impulse voltage generator in the testing hall which has high quality shielding materials that guarantee the background Partial Discharge in the test hall is less than 2pC. The first class hardware facilities, perfect testing method, good testing environment and powerful production capacity guarantee the stability and excellence of our products.

Overview of Insulation Outlet Device and Insulation Parts Electrical Accessory Subsidiary has a strong ability of scientific research, development and manufacturing based on TBEA’s strong scientific research and technology capacity. Our company has long been supplying insulation outlet device for AC and DC transformer, zinc oxide lightning arrester and a variety of insulation parts used in the transformers to TBEA. Currently, our company has the ability of assembling and manufacturing AC 1000kV &below and DC ±800kV & below insulation outlet device. Meanwhile, we are also capable of repairing foreign and domestic insulation outlet device. Our company can use high quality insulation materials produced by designated foreign or domestic manufacturers as per our customers’ requirements and process various insulation parts adopting advanced technics and equipments.

Overview of Insulation Outlet Device and Insulation Parts Electrical Accessory Subsidiary has a strong ability of scientific research, development and manufacturing based on TBEA’s strong scientific research and technology capacity. Our company has long been supplying insulation outlet device for AC and DC transformer, zinc oxide lightning arrester and a variety of insulation parts used in the transformers to TBEA. Currently, our company has the ability of assembling and manufacturing AC 1000kV &below and DC ±800kV & below insulation outlet device. Meanwhile, we are also capable of repairing foreign and domestic insulation outlet device. Our company can use high quality insulation materials produced by designated foreign or domestic manufacturers as per our customers’ requirements and process various insulation parts adopting advanced technics and equipments.  The product type 1. ±800kV Oil-gas DC bushing 2. ±400kV&below Resin-impregnated paper condenser DC bushing 3. 1700kV&below Oil-impregnated capacitor type bushing 4. 800kV Oil-impregnated capacitor type bushing with composite external insulation 5. 252kV&below Resin-impregnated paper condenser AC bushing 6. 252kV&below ETG bushing The insulation outlet device for converter transformer Insulation parts

The product type 1. ±800kV Oil-gas DC bushing 2. ±400kV&below Resin-impregnated paper condenser DC bushing 3. 1700kV&below Oil-impregnated capacitor type bushing 4. 800kV Oil-impregnated capacitor type bushing with composite external insulation 5. 252kV&below Resin-impregnated paper condenser AC bushing 6. 252kV&below ETG bushing The insulation outlet device for converter transformer Insulation parts

Project ±800kV Oil-SF6 DC Bushings Hami-Zhengzhou DC Hami Substation Project ±400kV Oil-SF6 DC Bushings Jinsu Project, Yulong Convertor Station Project ±186kV Resin-Impregnated Paper DC Bushings Gaoling Back-to-Back Extension Project ±1700kV Oil-Impregnated Paper Capacitor Type Bushings India Energy Company Test Transformer Project 800kV Oil-Impregnated Paper Capacitor Type Bushings India UPPTCL Project 550kV Oil-Impregnated Paper Capacitor Type Bushings Shanghai Fengjing Power Plant Project 330kV Oil-Impregnated Paper Capacitor Type Bushings Yulin Power Plant Project 220kV Oil-Impregnated Paper Capacitor Type Bushings Huaneng Tongjiang Wind Power Generation Project

Project ±800kV Oil-SF6 DC Bushings Hami-Zhengzhou DC Hami Substation Project ±400kV Oil-SF6 DC Bushings Jinsu Project, Yulong Convertor Station Project ±186kV Resin-Impregnated Paper DC Bushings Gaoling Back-to-Back Extension Project ±1700kV Oil-Impregnated Paper Capacitor Type Bushings India Energy Company Test Transformer Project 800kV Oil-Impregnated Paper Capacitor Type Bushings India UPPTCL Project 550kV Oil-Impregnated Paper Capacitor Type Bushings Shanghai Fengjing Power Plant Project 330kV Oil-Impregnated Paper Capacitor Type Bushings Yulin Power Plant Project 220kV Oil-Impregnated Paper Capacitor Type Bushings Huaneng Tongjiang Wind Power Generation Project

Send your inquiry to this supplier