1 / 1

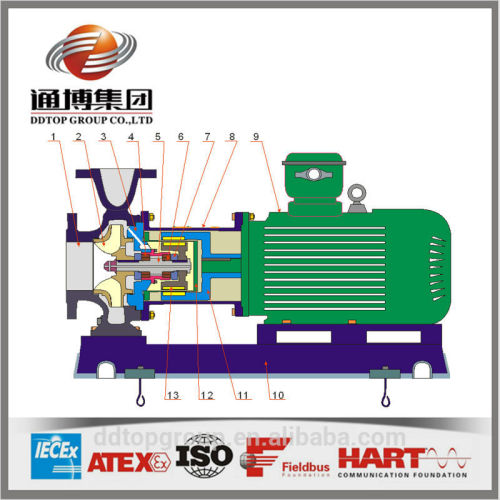

oil and gas production chemical dosing pumps

Get Latest Price

Send Inquiry

| Model No. : | IMC |

|---|---|

| Brand Name : | DDTOP |

Dandong Top Electronics Instrument (Group) Co., Ltd.

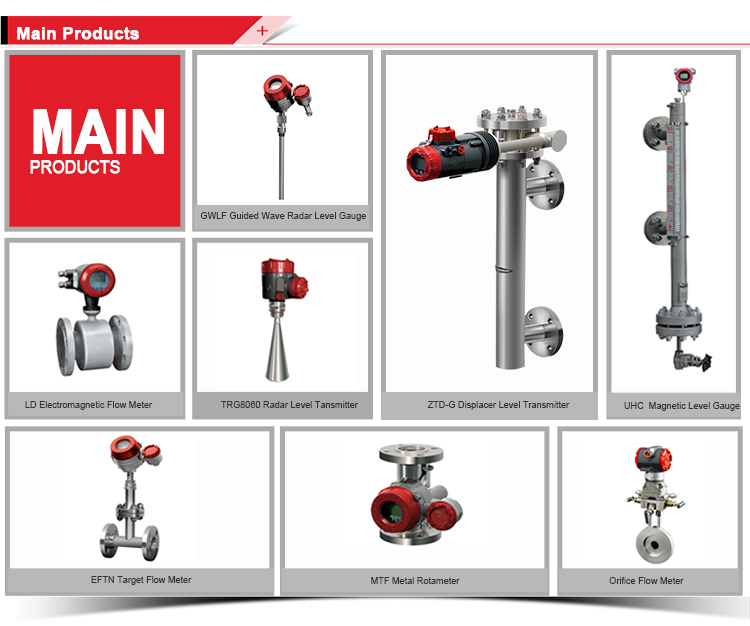

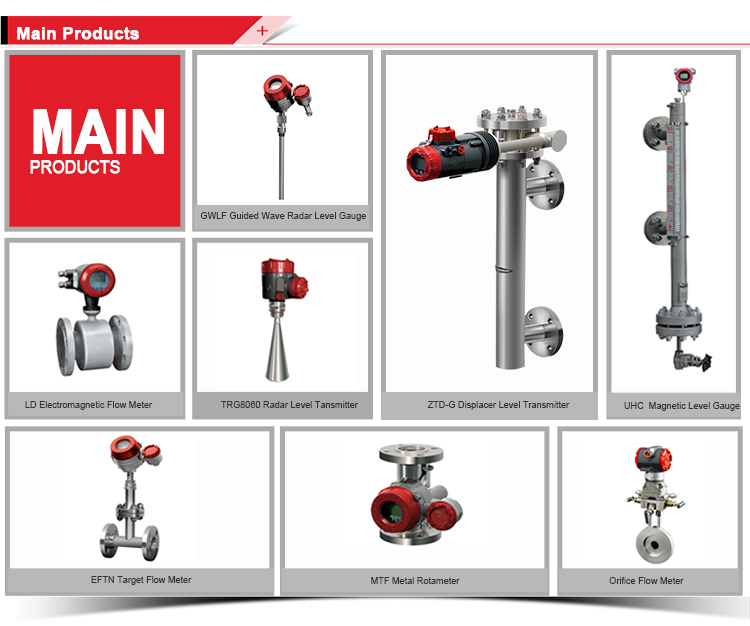

You might also like

Product description

oil and gas production chemical dosing pumps Product Description Introduction IMC series magnetic drive pumps are standard chemical process pumps, which can be classified into horizontal, cantilever, single-stage, single suction centrifugal pumps. They all comply with DIN24256, ISO2858, GB5662-85, API685 standards. The greatest figure of the pumps is 100% non-leakage. They are suitable for transferring liquids, whatever is low-temperature, or high-temperature, neutral or corrosive, clean or toxic, flammable or explosive liquid. Features The pump has advanced magnet force transmission structure which was cooperatively developed by Dandong Top Pump Co., Ltd (hereinafter referred to as DDTOP PUMP) and Jiangsu University of Science and Technology. The technology makes the pumps be the products with high technology. The design of arrangement of magnet steels and magnetic circuit features compact sizes, reliable performance and high transmission efficiency. Because of its optimal design of the overall structure, as well as its unique nature of magnetic coupling in magnetic drive device, the product also has characteristics of small noise and vibration. Furthermore, suitable materials with reasonable dimensions create an excellent pair of friction components. The axial forces balance device with scientific design makes the pump have high efficiency; the rotating parts have lower friction rate and lower failure rate so that the pump has a long service life with lower failure rate. Applications This pump can substitutes for shaft seal pump and canned motor pump, which is suitable for transporting different kinds of liquids, particle containing, clean but flammable explosive, toxic, corrosive or valuable liquid, in chemical, petrochemical, pharmaceutical, printing and dyeing and other industries. No leakage magnetic drive pump is an ideal chemical equipment, which can bring those enterprises in above mentioned industries higher both economic and social benefits in aspects of increasing production and cutting expenditure, eliminate pollution, environment protection, safety in production and labor protection. Working principle magnetic drive pump is applied with principles of magnetomechanics to realize non-contact torque transmission, eliminate seal device (packing seal or mechanical seal ) of ordinary centrifugal pumps, replace dynamic seal with static seal so as to create a new non-leak chemical process pump. As a achievement of high technology in contemporary pump industry, magnetic pump is a ideal product to get rid of industrial leakage, prevent pollution, keep clean environment. Its working principle is: Motor connects the external magnetic rotor (i.e. the driving rotor) to compose the driving unit, while, the impeller links the inner magnet rotor as a driven unit. Between the inner magnetic rotor and the external rotor, there is an isolation cylinder which separates the latter from the former completely. The inner magnetic rotor is in the medium. The magnetic pole from the external magnetic rotor couples with the pole from the inner magnetic rotor to create pairs of pull and push forces. Those pairs of pull-push forces form an integrated pull-push force with which the motor drives the inner magnetic rotor,the pump shaft and the impeller to rotate synchronously.

Company Information

Company Information

Ambient temperature | less than 40 °C |

Flow rate (Q) | 6.3 to 400m3 / h |

Head (H) | 5 to 136m |

Dynamic viscosity | μ ≤ 20cP |

Rpm (n) | 1450/2900r/min |

Operating temperature | -45 to 250 °C |

Operating Pressure | 2.5MPa |

Drive power (equipped motor power) | 2.2 to 280KW |

Company Information

Company Information

Send your inquiry to this supplier

Send Inquiry