Video

1 / 1

O2 Generator Professional Oxygen Pressure Swing Adsorption

| Old and new : | New |

|---|

Shenzhen, Guangdong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

O2 Gas Generator Professional Oxygen Pressure Swing Adsorption Plant Nitrogen Oxygen Machine

Features:

● Fast start-up, qualified oxygen can be provided within 15-30 minutes;

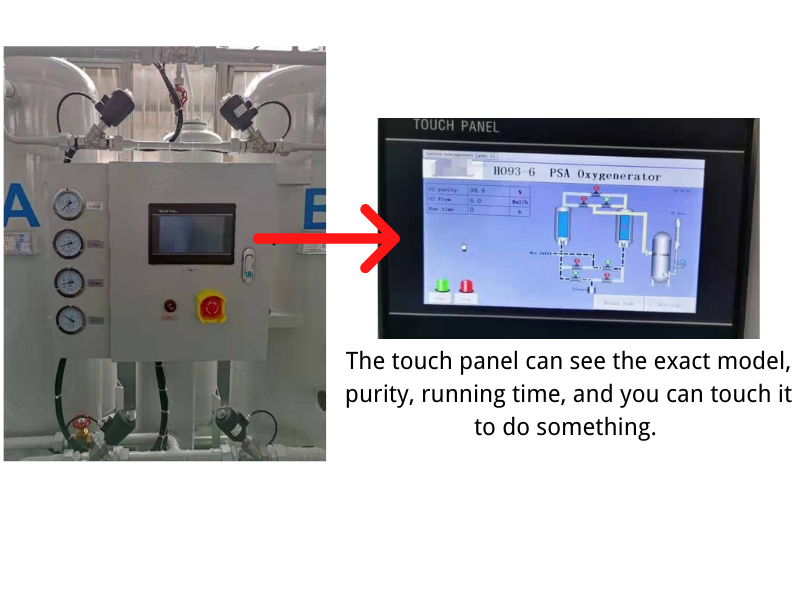

● The oxygen device equipment is fully automatic, and the whole process can be unattended;

● Efficient molecular sieve packing, tighter, more solid, and longer service life;

● The pressure, purity, and flow are stable and adjustable to meet the different needs of customers;

● Reasonable structure, safety and stability, low energy consumption;

Principle:

This process uses molecular sieves with capillary pores as adsorbents, and utilizes the difference in diffusion rate of oxygen molecule O2 and nitrogen molecule N2 in molecular sieve. Nitrogen and CO2 molecules in the air are absorbed into the pores, while most of the oxygen molecules O2 flow through the capillary pores into the oxygen collecting and storing tank in the later stage to be enriched. Molecular sieve has the characteristics of adding air pressure adsorption capacity increasing, and reducing air pressure adsorption capacity reducing, using this characteristic, the pressure swing adsorption method can be used to carry out continuous and uninterrupted oxygen and nitrogen separation. So as to achieve the preparation of 35%-95% purity room temperature oxygen.

The PSA Oxygen Concentrator adopts a dual-tower parallel design. When tower A reaches saturation, it will switch to tower B for oxygen production through pressure equalization and other processes. At this time, tower A is vented and purged and regenerated, waiting for the next cycle of the oxygen generator; thus, double-tower alternate oxygen production is realized. In the latter stage of the oxygen collection process tank, high-purity continuous supply of oxygen is obtained, and finally the pressure is stabilized by adjusting the pressure and then transported to the gas point through the pipeline.

Precautions:

In addition to correct use and operation, daily meticulous routine inspection and the operation record is very important, it will find the problem in time and try to eliminate the fault as much as possible.Keep the equipment in good working condition all the time during use, better to serve the hospital and PSA Oxygen Plant.

KunPeng is located in Shenzhen, China. We specialized inView More

1 View More

Video

Shenzhen, Guangdong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier