1 / 5

New Type Wet Small Ball Mill For Sale

| Model No. : | Φ2400×3600 |

|---|---|

| Brand Name : | Zoneding |

| Type : | Ball Mill |

Product description

New Type Wet Small Ball Mill For Sale

Introduction of Cement Grinding Ball Mill

Cement Ball Mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, Dry Grinding Ball Mill must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as vibrating screen, spiral classifier, cyclone and air classifier are used for classifying the discharge from ball mills. Vibrating Ball Mill is the key equipment for grinding many materials into fine powder, widely used in cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, etc. Ball Mill can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Features & Advantages of Cement Grinding Ball Mill

1. High production capacity and crushing ratio;

2. Low power consumption, uniform particle size;

3. Simple structure, easy to operate;

4. Low investment cost, big profit;

5. Perfect services, both pre-sales services and after-sales services.

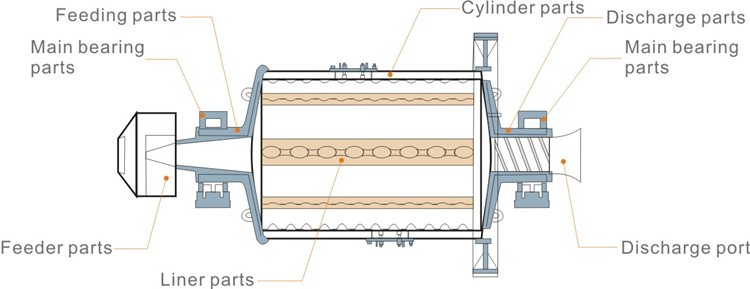

Working Principle of Cement Grinding Ball Mill

The ball mill machine is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Technical Parameters of Cement Grinding Ball Mill

| Model | Speed (r/min) | Max. weight of balls (t) | Input size (mm) | Output size (mm) | power (kw) | Capacity (t/h) | Weight(t) |

| Φ2400×3600 | 21 | 28 | ≤25 | 0.047-0.4 | 320 | 8-60 | 47 |

Cement Grinding Ball Mill Displayed in Our Workshop

Case:

Ball Mill Grinding Plant for Quartz Sand

Ball Mill: two sets

Model: 2.2×7.0

Capacity: 5-6t/h

Final product size: 325mesh.

Send your inquiry to this supplier