1 / 1

New high-performance solid control decanter centrifuge

Get Latest Price

Send Inquiry

| Brand Name : | HUADING |

|---|

Yixing Huading Food Machinery Co., Ltd.

You might also like

Product description

Specifications Decanter centrifuge with solid wall bowl,

- VFD driving

- Continuous operation

- Fully automatic control

- Low maintenance

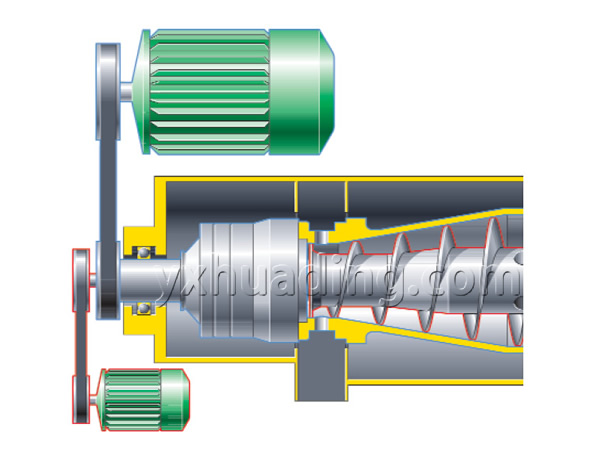

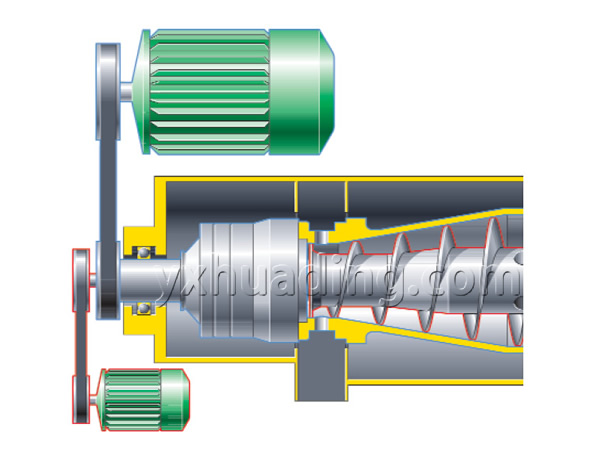

High-performance solid control decanter centrifuge Applications This series decanter centrifuge from Huading Separator is a continuously operating horizontal solid wall centrifuge for spirulina treatment applications. It is the ideal for spirulina concentrate, harveting and so on. The spirulina suspension is fed directly into the centrifuge. Inside the centrifuge the suspension is separated into a mostly clear water phase and an spirulina concentrate. Working principle - 1. Feed - 2. Liquid phase - 3. Solids phase - 4. Pond - 5. Dry beach The feed suspension is introduced through an inlet pipe into the feed zone of the conveyor where it is accelerated and directed into the interior of the bowl. The settled solids are conveyed axially towards the small end of the bowl by means of the screw conveyor, which rotates at a slightly different speed than the bowl. On the way to the discharge ports the solids are lifted out of the pond up along the dry beach. The solids are finally discharged from the bowl through the discharge ports into the collecting chamber of the casing that surrounds the bowl. From there the solids are removed by gravity through the outlet funnel. The liquid phase forming a hollow cylinder due to the centrifugal force, and flows towards the large end of the bowl. There the liquid overflows adjustable plate dams into the centrate chamber of the casing and is discharged by gravity.

- 1. Feed - 2. Liquid phase - 3. Solids phase - 4. Pond - 5. Dry beach The feed suspension is introduced through an inlet pipe into the feed zone of the conveyor where it is accelerated and directed into the interior of the bowl. The settled solids are conveyed axially towards the small end of the bowl by means of the screw conveyor, which rotates at a slightly different speed than the bowl. On the way to the discharge ports the solids are lifted out of the pond up along the dry beach. The solids are finally discharged from the bowl through the discharge ports into the collecting chamber of the casing that surrounds the bowl. From there the solids are removed by gravity through the outlet funnel. The liquid phase forming a hollow cylinder due to the centrifugal force, and flows towards the large end of the bowl. There the liquid overflows adjustable plate dams into the centrate chamber of the casing and is discharged by gravity.  - 0. Food - 1. Light liquid phase

- 0. Food - 1. Light liquid phase

- 2. Heavy liquid phase - 3. Solids phase The light liquid phase is discharged into the casing through radial holes in the large end hub. The heavy liquid phase is discharged through axial holes in the large end hub. The liquid radius for the light liquid phase is smaller than the radius for the heavy liquid phase. The liquid level is controlled by plate dams. In order to prevent the light liquid phase from leaving the bowl through the heavy liquid phase outlet, a separating plate is placed on the inside of the large end hub. The heavy liquid phase has to pass under the separating plate before being discharged into the casing. The liquid radius for the heavy liquid phase is controlled by plate dams. The solids are discharged in the normal way. Features All parts coming into contact with the product are made of stainless steel. 3-phase AC motor for controlled torque starting via frequency converter Bowl speed is adjustable via VFD to obtain the required G-force for optimized separation Pond depth in the bowl is adjustable for optimized balance between liquid clarity and solids dryness Conveying speed is adjustable for optimized balance between liquid Low personnel costs due to continuous and automatic operation. Highest g-force for higher solids output Automatic adjustment of differential speed via VFD Two motor drive Belts for both primary motor and secondary motor Materials The bowl, conveyor, inlet tube, outlets, cover and other parts in direct contact with the process media are all made of stainless steel. The discharge ports, conveyor flights and feed zone are protected with materials that are highly resistant to erosion. The frame is made of mild steel with an epoxy enamel finish. Design The rotating part of these decanter centrifuges is mounted on a compact, in-line frame, with main bearings at both ends. Vibration dampers are placed under the frame. The rotating part is enclosed in a casing with a cover and a bottom section with integrated outlets for both solids and the liquid being removed. Decanter centrifuge drive system One motor drive, this is a very simple design and are therefore cheap to purchase and operate. One motor drive are used when the solids volume is constant, the solids are easy to convey and the requirements regarding the residual water content of the solids are not very stringent, in other words, bowl and differential speed regulating facilities are not necessary. The input shaft of the drive is set in motion by the main motor via a second belt drive. This generates the differential speed as a function of bowl speed and gear transmission. This can be easily changed by replacing the belt pulleys.

One motor drive, this is a very simple design and are therefore cheap to purchase and operate. One motor drive are used when the solids volume is constant, the solids are easy to convey and the requirements regarding the residual water content of the solids are not very stringent, in other words, bowl and differential speed regulating facilities are not necessary. The input shaft of the drive is set in motion by the main motor via a second belt drive. This generates the differential speed as a function of bowl speed and gear transmission. This can be easily changed by replacing the belt pulleys.  Two motor drive, it enable the differential speed to be regulated cost-effectively under good operating conditions; wide regulating ranges are possible. The secondary motor sets the input shaft of the gear in motion and generates the differential speed as a function of bowl speed and gear transmission. The differential speed can easily be regulated by changing the motor speed. Two motor drive are used whenever solid volumes fluctuate significantly, when solids are conveyed under difficult conditions and when particularly stringent requirements are applicable with regard to residual water content.

Two motor drive, it enable the differential speed to be regulated cost-effectively under good operating conditions; wide regulating ranges are possible. The secondary motor sets the input shaft of the gear in motion and generates the differential speed as a function of bowl speed and gear transmission. The differential speed can easily be regulated by changing the motor speed. Two motor drive are used whenever solid volumes fluctuate significantly, when solids are conveyed under difficult conditions and when particularly stringent requirements are applicable with regard to residual water content.  Hydro drive, it works in a way which is similar to that of the two motor drive. The difference is to be seen in the design.Instead of the mechanical gear, a rotating hydromotor is installed; this is supplied with hydraulic regulation by a pump unit. Because the differential speed is proportionate to the conveyed quantity of oil, automatic regulation can be provided without any problem. wear protection

Hydro drive, it works in a way which is similar to that of the two motor drive. The difference is to be seen in the design.Instead of the mechanical gear, a rotating hydromotor is installed; this is supplied with hydraulic regulation by a pump unit. Because the differential speed is proportionate to the conveyed quantity of oil, automatic regulation can be provided without any problem. wear protection

Experience Huading Separator has been developing and manufacturing decanters for over 15 years and is one of the Chinese leading decanter manufacturers.Huading Separator has more experience and expertise than any other decanter manufacturer when it comes to applying and using decanters for the purpose of industrial & municipal wastewater treatment.

Experience Huading Separator has been developing and manufacturing decanters for over 15 years and is one of the Chinese leading decanter manufacturers.Huading Separator has more experience and expertise than any other decanter manufacturer when it comes to applying and using decanters for the purpose of industrial & municipal wastewater treatment.

For more information, please refer to:huading-separator.com

- VFD driving

- Continuous operation

- Fully automatic control

- Low maintenance

High-performance solid control decanter centrifuge Applications This series decanter centrifuge from Huading Separator is a continuously operating horizontal solid wall centrifuge for spirulina treatment applications. It is the ideal for spirulina concentrate, harveting and so on. The spirulina suspension is fed directly into the centrifuge. Inside the centrifuge the suspension is separated into a mostly clear water phase and an spirulina concentrate. Working principle

- 1. Feed - 2. Liquid phase - 3. Solids phase - 4. Pond - 5. Dry beach The feed suspension is introduced through an inlet pipe into the feed zone of the conveyor where it is accelerated and directed into the interior of the bowl. The settled solids are conveyed axially towards the small end of the bowl by means of the screw conveyor, which rotates at a slightly different speed than the bowl. On the way to the discharge ports the solids are lifted out of the pond up along the dry beach. The solids are finally discharged from the bowl through the discharge ports into the collecting chamber of the casing that surrounds the bowl. From there the solids are removed by gravity through the outlet funnel. The liquid phase forming a hollow cylinder due to the centrifugal force, and flows towards the large end of the bowl. There the liquid overflows adjustable plate dams into the centrate chamber of the casing and is discharged by gravity.

- 1. Feed - 2. Liquid phase - 3. Solids phase - 4. Pond - 5. Dry beach The feed suspension is introduced through an inlet pipe into the feed zone of the conveyor where it is accelerated and directed into the interior of the bowl. The settled solids are conveyed axially towards the small end of the bowl by means of the screw conveyor, which rotates at a slightly different speed than the bowl. On the way to the discharge ports the solids are lifted out of the pond up along the dry beach. The solids are finally discharged from the bowl through the discharge ports into the collecting chamber of the casing that surrounds the bowl. From there the solids are removed by gravity through the outlet funnel. The liquid phase forming a hollow cylinder due to the centrifugal force, and flows towards the large end of the bowl. There the liquid overflows adjustable plate dams into the centrate chamber of the casing and is discharged by gravity.  - 0. Food - 1. Light liquid phase

- 0. Food - 1. Light liquid phase- 2. Heavy liquid phase - 3. Solids phase The light liquid phase is discharged into the casing through radial holes in the large end hub. The heavy liquid phase is discharged through axial holes in the large end hub. The liquid radius for the light liquid phase is smaller than the radius for the heavy liquid phase. The liquid level is controlled by plate dams. In order to prevent the light liquid phase from leaving the bowl through the heavy liquid phase outlet, a separating plate is placed on the inside of the large end hub. The heavy liquid phase has to pass under the separating plate before being discharged into the casing. The liquid radius for the heavy liquid phase is controlled by plate dams. The solids are discharged in the normal way. Features All parts coming into contact with the product are made of stainless steel. 3-phase AC motor for controlled torque starting via frequency converter Bowl speed is adjustable via VFD to obtain the required G-force for optimized separation Pond depth in the bowl is adjustable for optimized balance between liquid clarity and solids dryness Conveying speed is adjustable for optimized balance between liquid Low personnel costs due to continuous and automatic operation. Highest g-force for higher solids output Automatic adjustment of differential speed via VFD Two motor drive Belts for both primary motor and secondary motor Materials The bowl, conveyor, inlet tube, outlets, cover and other parts in direct contact with the process media are all made of stainless steel. The discharge ports, conveyor flights and feed zone are protected with materials that are highly resistant to erosion. The frame is made of mild steel with an epoxy enamel finish. Design The rotating part of these decanter centrifuges is mounted on a compact, in-line frame, with main bearings at both ends. Vibration dampers are placed under the frame. The rotating part is enclosed in a casing with a cover and a bottom section with integrated outlets for both solids and the liquid being removed. Decanter centrifuge drive system

One motor drive, this is a very simple design and are therefore cheap to purchase and operate. One motor drive are used when the solids volume is constant, the solids are easy to convey and the requirements regarding the residual water content of the solids are not very stringent, in other words, bowl and differential speed regulating facilities are not necessary. The input shaft of the drive is set in motion by the main motor via a second belt drive. This generates the differential speed as a function of bowl speed and gear transmission. This can be easily changed by replacing the belt pulleys.

One motor drive, this is a very simple design and are therefore cheap to purchase and operate. One motor drive are used when the solids volume is constant, the solids are easy to convey and the requirements regarding the residual water content of the solids are not very stringent, in other words, bowl and differential speed regulating facilities are not necessary. The input shaft of the drive is set in motion by the main motor via a second belt drive. This generates the differential speed as a function of bowl speed and gear transmission. This can be easily changed by replacing the belt pulleys.  Two motor drive, it enable the differential speed to be regulated cost-effectively under good operating conditions; wide regulating ranges are possible. The secondary motor sets the input shaft of the gear in motion and generates the differential speed as a function of bowl speed and gear transmission. The differential speed can easily be regulated by changing the motor speed. Two motor drive are used whenever solid volumes fluctuate significantly, when solids are conveyed under difficult conditions and when particularly stringent requirements are applicable with regard to residual water content.

Two motor drive, it enable the differential speed to be regulated cost-effectively under good operating conditions; wide regulating ranges are possible. The secondary motor sets the input shaft of the gear in motion and generates the differential speed as a function of bowl speed and gear transmission. The differential speed can easily be regulated by changing the motor speed. Two motor drive are used whenever solid volumes fluctuate significantly, when solids are conveyed under difficult conditions and when particularly stringent requirements are applicable with regard to residual water content.  Hydro drive, it works in a way which is similar to that of the two motor drive. The difference is to be seen in the design.Instead of the mechanical gear, a rotating hydromotor is installed; this is supplied with hydraulic regulation by a pump unit. Because the differential speed is proportionate to the conveyed quantity of oil, automatic regulation can be provided without any problem. wear protection

Hydro drive, it works in a way which is similar to that of the two motor drive. The difference is to be seen in the design.Instead of the mechanical gear, a rotating hydromotor is installed; this is supplied with hydraulic regulation by a pump unit. Because the differential speed is proportionate to the conveyed quantity of oil, automatic regulation can be provided without any problem. wear protection

Experience Huading Separator has been developing and manufacturing decanters for over 15 years and is one of the Chinese leading decanter manufacturers.Huading Separator has more experience and expertise than any other decanter manufacturer when it comes to applying and using decanters for the purpose of industrial & municipal wastewater treatment.

Experience Huading Separator has been developing and manufacturing decanters for over 15 years and is one of the Chinese leading decanter manufacturers.Huading Separator has more experience and expertise than any other decanter manufacturer when it comes to applying and using decanters for the purpose of industrial & municipal wastewater treatment. | bowl ID (mm) | bowl speed (rpm) | L / D | g - force | capacity (m3/h) | solids removal (m3/h) | primary motor (Kw) | Weight (Kg) | Dimension (mm) |

| 220 | 4800~5400 | 3.0~5.0 | 2000~3500 | 3~5 | 0.4 | 11 | 760 | 1600×1100×850 |

| 300 | 4200~4600 | 3.0~5.0 | 2000~3500 | 3~15 | 0.8 | 11~15 | 1500 | 2470×1230×850 |

| 350 | 3700~4200 | 3.0~5.0 | 2000~3500 | 5~20 | 1.2 | 5~22 | 2000 | 2790×1300×880 |

| 400 | 3200~3900 | 3.0~4.8 | 2000~3500 | 5~30 | 2 | 18.5~30 | 2600 | 2950×1400×850 |

| 450 | 3000~3700 | 3.0~5.0 | 2000~3500 | 5~45 | 2.5 | 22~37 | 3200 | 3300×1500×920 |

| 530 | 2700~3450 | 3.0~5.0 | 2000~3500 | 10~80 | 5 | 30~55 | 5200 | 3730×1600×1100 |

| 580 | 2600~3300 | 3.0~5.0 | 2000~3500 | 10~90 | 6 | 45~75 | 6900 | 4000×1400×1600 |

| 650 | 2400~3100 | 3.0~5.0 | 2000~3500 | 20~105 | 8 | 37~90 | 8200 | 4300×1900×1350 |

| 760 | 2200~2900 | 3.0~5.0 | 2000~3500 | 30~120 | 12 | 55~135 | 12000 | 5000×2500×1500 |

| 900 | 1800~2600 | 3.0~5.0 | 2000~3500 | 40~180 | 16 | 75~160 | 18000 | 6500×2700×1500 |

Send your inquiry to this supplier

Send Inquiry