1 / 4

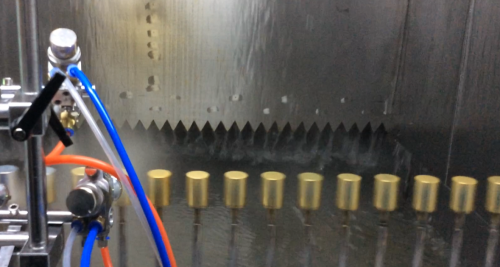

Nail Polish Cap Automatic UV Coating Line

| Model No. : | HYJ-392 |

|---|---|

| Brand Name : | HENGYIJIA |

| Type : | Spray Painting Line |

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Product description

Clean the nail polish paint line

I provide cosmetics nail polish cap automatic painting production line, portable computer keyboard, key cover, button and other special cleaning automatic painting equipment. Mobile phone shell surface spraying special automatic dust-free electrostatic spraying production line, high output, cleaning effect, UV effect can achieve the actual needs

Principle Features: loading and unloading - spraying - leveling - drying (or UV curing) - unloading, integrated automation cleaning coating equipment. Using man-machine interface input, PLC programming control, simple and reliable operation. The most prominent feature is the high yield (1200-1500 sets / hour gun), high pass rate (spray pass rate higher than 96%). Coating thickness uniformity and stability. Is the preferred device for mass production of mobile phone shells and keyboards.

The right product:

Mobile phone, camera, mp3, speaker box, toy, cosmetic box, keyboard, mouse. DVD and so on

Second, the spraying process:

Loading - Manual working Electrostatic dust removal - Automatic electrostatic dust removal - Automatic spraying - Vertical baking cooling - UV curing - Unloading.

III, Size: L 16 m × W 6 m × H 3 m. (Planning is based on the customer's store and product)

Fourth, the process data:

one. Chain conveyor speed: -8 m / min.

Gulf workpiece speed: 10-200r / min.

C. workpiece diameter size: 300mm × 400mm high.

day. Production: 400-8000 a / h (depending on workpiece size change).

Ie gun number: gun number: 2-12 (depending on product)

F. Spray method: workpiece rotation (forward, reverse) spray with each angle spray gun.

G. spray room: three wash, eddy current, negative pressure exhaust.

H Air Supplement:

Cleaning levels require the planning of different levels of gas supply filtration systems. Clean positive pressure fresh air supply, the initial effect, in fact, four filters using eddy current spray, positive pressure spray. Chain conveyor on my steel kennel oven, far infrared heating tube baking, import temperature control part of the control, can add UV curing furnace, clean room workshop static level dynamic level $.

A oven:

Color appearance, far infrared heating, rock wool insulation, SCR branch console. Can be used for UV curing furnace.

UV oven features:

1. ASU with 10,000 clean levels of air supply.

2.UV oven work style: continuous work plus rotation.

Ultraviolet lamp distance adjustable.

4. Time function of UV oven working time.

5. Adjustable UV intensity.

6. When the UV oven is stopped, the ASU will be delayed.

7. UV lamp operating current, temperature alarm function.

8. The current of the suction and motor shows current overload.

9. Automatically check and adjust positive pressure.

10. UV oven automatic alarm.

Vacuum metalization machine

Gun fixed UV painting line

Air Shower

Loading

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Send your inquiry to this supplier