1 / 6

mining separation heavy duty solid slurry pump

Get Latest Price

Send Inquiry

| Model No. : | AM(R) horiztonal centrifugal slurry pump |

|---|---|

| Brand Name : | An Pump |

Shijiazhuang An Pump Machinery Co., Ltd.

You might also like

Product description

Product Description AM(R) mining separation heavy duty solid slurry pump AM(R) mining separation heavy duty solid slurry pump is the centrifugal pump special used for slurry, liquid with solids or mud/sludge transfer pump major used at mining department.  When or where you need Slurry Pump? • To pump a medium where abrasive particles are present • To transport the productions required or as much solids as possible hydraulically

When or where you need Slurry Pump? • To pump a medium where abrasive particles are present • To transport the productions required or as much solids as possible hydraulically

The medium with few particles or not abrasive, which means the medium similar clear water that you could use clear water pumps, dirty water pumps or mud /sludge pumps is good enough

The Feature For AM mining separation heavy duty solid slurry pump The Extra-Thick Wet End Components make the AM(R) mining separation heavy duty solid slurry pump could handle the liquid with abrasive solid particles and extend the wear life Max, increase the mean time between failures with lowest maintenance by reasonable component arrangement!!!

The Feature For AM mining separation heavy duty solid slurry pump The Extra-Thick Wet End Components make the AM(R) mining separation heavy duty solid slurry pump could handle the liquid with abrasive solid particles and extend the wear life Max, increase the mean time between failures with lowest maintenance by reasonable component arrangement!!!  ● The Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and lowest maintenance

● The Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and lowest maintenance

● The Large, open internal passages designed to reduce internal velocities, maximize wear life and lowest maintenance

● Heavy duty construction with through-bolt design provides ease of maintenance and Min downtime

● The Replaceable and Interchangeable Wet End Parts are lower the stocking cost, easy to repair and Min downtime

● The Ductile iron fully lined casing provides durability,strength, safety, and long service life recommended while the Grey iron liner is the economic solution could satisfied most customers required especially when you dont need the pumps work at 24x7

● Minimal shaft/impeller overhang reduces shaft deflection and increases packing life and the mean time between failures

● Cartridge-style bearing assembly allows for maintenance in a clean environment without removal of the pump, resulting in reliable operation and prolonged bearing life, which is another way to increase the mean time between failures

● Grease or oil lubrication bearing assembly options offer ease of maintenance and reduced downtime

● Lower NPSH requirements results in enhanced hydraulic performance and extended the wear life

● The metal or rubber parts are available for different work conditions Max the wear life and lowest the maintenance cost

The Composition of AMR mining separation heavy duty solid slurry pump The AM(R) mining separation heavy duty solid slurry pump is end suction, cantiliever, horiztonal, centrifugal pump: The Material of AM(R) mining separation heavy duty solid slurry pump The AM(R) mining separation heavy duty solid slurry pump is the heavy duty pump special designed for mining and mineral, power plant and general industrial department.

The Material of AM(R) mining separation heavy duty solid slurry pump The AM(R) mining separation heavy duty solid slurry pump is the heavy duty pump special designed for mining and mineral, power plant and general industrial department.

New development High Chrome Cast Iron make AM(R) mining separation heavy duty solid slurry pump have the long time uselife. In some conditions, the new development Rubber materials have better performance when there is acd conditions. You could also find some rubber lined pump for your different required!

New R&D for the AM(R) mining separation heavy duty solid slurry pump Materials Our R&D department still continuously study the material and the latest materials of our AA37 make the AM(R) mining separation heavy duty solid slurry pump much better than any brand of the slurry pump in the market using. In some customers from Mexico, their slurry pump at AA37 work as long as 2 years without any repair or update and still going on!

New R&D for the AM(R) mining separation heavy duty solid slurry pump Materials Our R&D department still continuously study the material and the latest materials of our AA37 make the AM(R) mining separation heavy duty solid slurry pump much better than any brand of the slurry pump in the market using. In some customers from Mexico, their slurry pump at AA37 work as long as 2 years without any repair or update and still going on!

Click to know more...

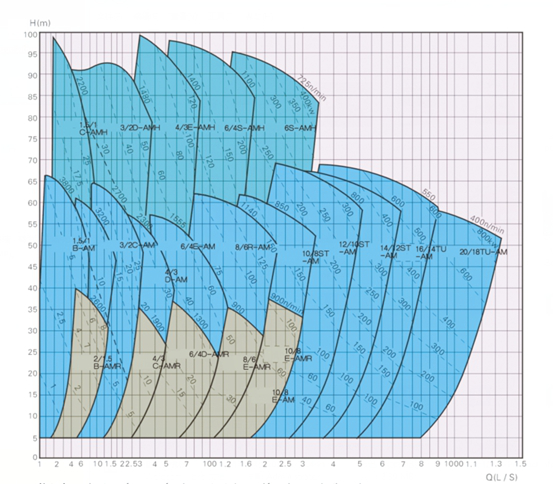

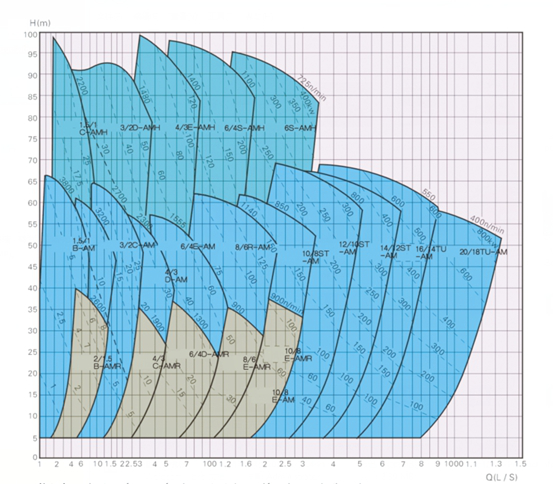

The Atlas curve of AM(R) mining separation heavy duty solid slurry pump You could know the range of our AM(R) mining separation heavy duty solid slurry pump performance range here or you could check the table by our experience if you are not professional or contact Roger at whatsapp +86 13780512387

The Application of AM(R) mining separation heavy duty solid slurry pump Our high quality AM(R) mining separation heavy duty solid slurry pump help us win great reputation from the customer all over the world in many different project.

The Application of AM(R) mining separation heavy duty solid slurry pump Our high quality AM(R) mining separation heavy duty solid slurry pump help us win great reputation from the customer all over the world in many different project.  Our Advantage

Our Advantage

Advantage OEM for old pump using both in material and size Strictly QA and QC from Raw materials to casing and assembly. Full pump and parts stocking for your 24x7 and Zero Inventory Plant Credit payment and Marketing strategies For the Mining company the credit could be 90 days or more or partly as the quality assurance as big as 20% over 1 years! For the sales agent, differnt promtion from market develop like SEO, Google; exhibition; training and free air ticket for VIP visiting mining operation etc to every details in sales processing! contact pump @ angroupcn.com for more ! Your best one stop pump solution: 1.Pump Model Choice And Technical Parameters Count

Advantage OEM for old pump using both in material and size Strictly QA and QC from Raw materials to casing and assembly. Full pump and parts stocking for your 24x7 and Zero Inventory Plant Credit payment and Marketing strategies For the Mining company the credit could be 90 days or more or partly as the quality assurance as big as 20% over 1 years! For the sales agent, differnt promtion from market develop like SEO, Google; exhibition; training and free air ticket for VIP visiting mining operation etc to every details in sales processing! contact pump @ angroupcn.com for more ! Your best one stop pump solution: 1.Pump Model Choice And Technical Parameters Count

According to you offer relevant equipment data, pipe condition,slurry character,working condition, through professional data calculate, so engineers can obtain accurate clear water performance parameters.

2.Structure Design And Wet Ends Materials study

According to you offer relevant equipment data, pipe condition,slurry character,working condition, through professional data calculate, so engineers can obtain accurate clear water performance parameters.

3.Mining System Design

An Pump provides pump system designs based on field data supplied by you,or when preferred,we will send engineers to your location to gather geological data necessary for designing a customized pumping system.

An Pump experienced pump engineers possess extensive knowledge of fluid and mechanical pumping systems. They provide optimized solutions including appropriate sized pumps, pipes, valves and various other system equipment,as well as employing the best suited material to lengthen life-cycle operation.

4.Attentive After Sales Service

An Pump offer all-round after sales service, send engineers guide for installation and training workers at scene, offer spare parts promptly.

Your Best Cooperative Partner, Not Only But Whole Supply Chain Management (Logistics) An Pump Machinery as one of the best slurry pump manufacturer, we are not only focus on our own production only but also every details from every ring of our supply chain.

We only work with the first level partner!!!

Successful Project

Successful Project

Some customer list and the visiting of the customer at our factory and the customer's site:

Some customer list and the visiting of the customer at our factory and the customer's site:

Part of customer list An Pump Machinery experienced at Mining project and click the pictures of know more... Customer visit us The customer visit us before shipment and click the pictures to know more... We are the customer site An Pump Machinery is your reliable vendor with after market service at any time, click to know more... Packing & Delivery

Part of customer list An Pump Machinery experienced at Mining project and click the pictures of know more... Customer visit us The customer visit us before shipment and click the pictures to know more... We are the customer site An Pump Machinery is your reliable vendor with after market service at any time, click to know more... Packing & Delivery  Certification

Certification  An Pump Machinery is the pump manufacturer nearly 50 years, your best partner of ISO, CE, SGS approved mining separation heavy duty solid slurry pump manufacturer! Company Information

An Pump Machinery is the pump manufacturer nearly 50 years, your best partner of ISO, CE, SGS approved mining separation heavy duty solid slurry pump manufacturer! Company Information  Contact Us Your 24x7 Hotline for mining separation heavy duty solid slurry pump We are your best slurry pump manufacturer and please click me to send your inquiry to let our engineer do the solution (quotation) for you!

Contact Us Your 24x7 Hotline for mining separation heavy duty solid slurry pump We are your best slurry pump manufacturer and please click me to send your inquiry to let our engineer do the solution (quotation) for you!  The Slurry Pump Related You may need more different type of slurry pump for your project like Vertical Sump Slurry pump or submersible slurry pump, sometimes, you may need large capacity slurry pump or high pressure slurry pump. Please click the pictures below to know more:

The Slurry Pump Related You may need more different type of slurry pump for your project like Vertical Sump Slurry pump or submersible slurry pump, sometimes, you may need large capacity slurry pump or high pressure slurry pump. Please click the pictures below to know more:

Please click the contact to send inquiry to us... FAQ Frequently Asked Question for mining separation heavy duty solid slurry pump 1. Q: Are you a trading company or manufacture?

Please click the contact to send inquiry to us... FAQ Frequently Asked Question for mining separation heavy duty solid slurry pump 1. Q: Are you a trading company or manufacture?

A: An Pump Machinery Co., Ltd is a real large professional manufacturer since 1982 year, in China, produce with our own factory.

2. Q: what's your factory workshops ?

A: My factory produce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc.

Warmly welcome to visit & test my factory any time.

Click to see the video of An Pump Machinery... Click to see more pictures of An Pump Machinery...

3. Q: How about your slurry pump price?

A: We are sure our price is factory price, and insist high quality for our long term cooperation.

4. Q: What is your slurry pump material ?

A: AM series slurry pump materialhigh Cr Mo Ni alloy, super abrasive-resistant metal.

Shaft & Shaft sleeve material is stainless steel alloy.

5.Q: What kind of liquid can your slurry transfer?

A: Liquid range: water+ sand, solid, sludge, gravel, stones, chemical etc.

6. Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end.

Our factory has 15~30 QC.

7. Q: Is it easy for customers to change the parts by myself ?

A: yes, the structure is simple ,customers can change it very easily. We will also supply you maintenance tools for free.

8. Q: How to do if the pump or parts have operation problem within your warranty?

A: Tell me details timely, and show me pictures, we will send you solution at once without any hesistation.

9. Q: Can you install the electric motor or diesel engine with the pump for us ?

A: yes, we can, it's no problem, we are experienced in this .

10: Q: .we don't know which pump model we need ,can you help us ?

A: yes, please tell me your detail requirements, include liquid, flow rate, head etc,

my engineers teal will calculate & select most suitable pump model for you, offer pump solution for you.

11. Q:How long can you reply us if we send an inquiry ?

A: Generally within 2 hours, we will send you official quotation sheet, with price, technology data, performance curve, dimension etc.

12. Q: How can i contact you ?

A: Contact detail information

Roger Chen

Email: roger @angroupcn.com

Skype: chenroger1215

Tel: 008613780512387 (whatsapp/wechat)

Anything thing need help, please call me any time, i will try best to help you.

When or where you need Slurry Pump? • To pump a medium where abrasive particles are present • To transport the productions required or as much solids as possible hydraulically

When or where you need Slurry Pump? • To pump a medium where abrasive particles are present • To transport the productions required or as much solids as possible hydraulicallyThe medium with few particles or not abrasive, which means the medium similar clear water that you could use clear water pumps, dirty water pumps or mud /sludge pumps is good enough

The Feature For AM mining separation heavy duty solid slurry pump The Extra-Thick Wet End Components make the AM(R) mining separation heavy duty solid slurry pump could handle the liquid with abrasive solid particles and extend the wear life Max, increase the mean time between failures with lowest maintenance by reasonable component arrangement!!!

The Feature For AM mining separation heavy duty solid slurry pump The Extra-Thick Wet End Components make the AM(R) mining separation heavy duty solid slurry pump could handle the liquid with abrasive solid particles and extend the wear life Max, increase the mean time between failures with lowest maintenance by reasonable component arrangement!!!  ● The Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and lowest maintenance

● The Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and lowest maintenance● The Large, open internal passages designed to reduce internal velocities, maximize wear life and lowest maintenance

● Heavy duty construction with through-bolt design provides ease of maintenance and Min downtime

● The Replaceable and Interchangeable Wet End Parts are lower the stocking cost, easy to repair and Min downtime

● The Ductile iron fully lined casing provides durability,strength, safety, and long service life recommended while the Grey iron liner is the economic solution could satisfied most customers required especially when you dont need the pumps work at 24x7

● Minimal shaft/impeller overhang reduces shaft deflection and increases packing life and the mean time between failures

● Cartridge-style bearing assembly allows for maintenance in a clean environment without removal of the pump, resulting in reliable operation and prolonged bearing life, which is another way to increase the mean time between failures

● Grease or oil lubrication bearing assembly options offer ease of maintenance and reduced downtime

● Lower NPSH requirements results in enhanced hydraulic performance and extended the wear life

● The metal or rubber parts are available for different work conditions Max the wear life and lowest the maintenance cost

The Composition of AMR mining separation heavy duty solid slurry pump The AM(R) mining separation heavy duty solid slurry pump is end suction, cantiliever, horiztonal, centrifugal pump:

The Material of AM(R) mining separation heavy duty solid slurry pump The AM(R) mining separation heavy duty solid slurry pump is the heavy duty pump special designed for mining and mineral, power plant and general industrial department.

The Material of AM(R) mining separation heavy duty solid slurry pump The AM(R) mining separation heavy duty solid slurry pump is the heavy duty pump special designed for mining and mineral, power plant and general industrial department. New development High Chrome Cast Iron make AM(R) mining separation heavy duty solid slurry pump have the long time uselife. In some conditions, the new development Rubber materials have better performance when there is acd conditions. You could also find some rubber lined pump for your different required!

New R&D for the AM(R) mining separation heavy duty solid slurry pump Materials Our R&D department still continuously study the material and the latest materials of our AA37 make the AM(R) mining separation heavy duty solid slurry pump much better than any brand of the slurry pump in the market using. In some customers from Mexico, their slurry pump at AA37 work as long as 2 years without any repair or update and still going on!

New R&D for the AM(R) mining separation heavy duty solid slurry pump Materials Our R&D department still continuously study the material and the latest materials of our AA37 make the AM(R) mining separation heavy duty solid slurry pump much better than any brand of the slurry pump in the market using. In some customers from Mexico, their slurry pump at AA37 work as long as 2 years without any repair or update and still going on! Click to know more...

The Atlas curve of AM(R) mining separation heavy duty solid slurry pump You could know the range of our AM(R) mining separation heavy duty solid slurry pump performance range here or you could check the table by our experience if you are not professional or contact Roger at whatsapp +86 13780512387

The Application of AM(R) mining separation heavy duty solid slurry pump Our high quality AM(R) mining separation heavy duty solid slurry pump help us win great reputation from the customer all over the world in many different project.

The Application of AM(R) mining separation heavy duty solid slurry pump Our high quality AM(R) mining separation heavy duty solid slurry pump help us win great reputation from the customer all over the world in many different project.  Our Advantage

Our Advantage

Advantage OEM for old pump using both in material and size Strictly QA and QC from Raw materials to casing and assembly. Full pump and parts stocking for your 24x7 and Zero Inventory Plant Credit payment and Marketing strategies For the Mining company the credit could be 90 days or more or partly as the quality assurance as big as 20% over 1 years! For the sales agent, differnt promtion from market develop like SEO, Google; exhibition; training and free air ticket for VIP visiting mining operation etc to every details in sales processing! contact pump @ angroupcn.com for more ! Your best one stop pump solution: 1.Pump Model Choice And Technical Parameters Count

Advantage OEM for old pump using both in material and size Strictly QA and QC from Raw materials to casing and assembly. Full pump and parts stocking for your 24x7 and Zero Inventory Plant Credit payment and Marketing strategies For the Mining company the credit could be 90 days or more or partly as the quality assurance as big as 20% over 1 years! For the sales agent, differnt promtion from market develop like SEO, Google; exhibition; training and free air ticket for VIP visiting mining operation etc to every details in sales processing! contact pump @ angroupcn.com for more ! Your best one stop pump solution: 1.Pump Model Choice And Technical Parameters CountAccording to you offer relevant equipment data, pipe condition,slurry character,working condition, through professional data calculate, so engineers can obtain accurate clear water performance parameters.

2.Structure Design And Wet Ends Materials study

According to you offer relevant equipment data, pipe condition,slurry character,working condition, through professional data calculate, so engineers can obtain accurate clear water performance parameters.

3.Mining System Design

An Pump provides pump system designs based on field data supplied by you,or when preferred,we will send engineers to your location to gather geological data necessary for designing a customized pumping system.

An Pump experienced pump engineers possess extensive knowledge of fluid and mechanical pumping systems. They provide optimized solutions including appropriate sized pumps, pipes, valves and various other system equipment,as well as employing the best suited material to lengthen life-cycle operation.

4.Attentive After Sales Service

An Pump offer all-round after sales service, send engineers guide for installation and training workers at scene, offer spare parts promptly.

Your Best Cooperative Partner, Not Only But Whole Supply Chain Management (Logistics) An Pump Machinery as one of the best slurry pump manufacturer, we are not only focus on our own production only but also every details from every ring of our supply chain.

We only work with the first level partner!!!

Successful Project

Successful Project

Some customer list and the visiting of the customer at our factory and the customer's site:

Some customer list and the visiting of the customer at our factory and the customer's site:

Part of customer list An Pump Machinery experienced at Mining project and click the pictures of know more... Customer visit us The customer visit us before shipment and click the pictures to know more... We are the customer site An Pump Machinery is your reliable vendor with after market service at any time, click to know more... Packing & Delivery

Part of customer list An Pump Machinery experienced at Mining project and click the pictures of know more... Customer visit us The customer visit us before shipment and click the pictures to know more... We are the customer site An Pump Machinery is your reliable vendor with after market service at any time, click to know more... Packing & Delivery  Certification

Certification  An Pump Machinery is the pump manufacturer nearly 50 years, your best partner of ISO, CE, SGS approved mining separation heavy duty solid slurry pump manufacturer! Company Information

An Pump Machinery is the pump manufacturer nearly 50 years, your best partner of ISO, CE, SGS approved mining separation heavy duty solid slurry pump manufacturer! Company Information  Contact Us Your 24x7 Hotline for mining separation heavy duty solid slurry pump We are your best slurry pump manufacturer and please click me to send your inquiry to let our engineer do the solution (quotation) for you!

Contact Us Your 24x7 Hotline for mining separation heavy duty solid slurry pump We are your best slurry pump manufacturer and please click me to send your inquiry to let our engineer do the solution (quotation) for you!  The Slurry Pump Related You may need more different type of slurry pump for your project like Vertical Sump Slurry pump or submersible slurry pump, sometimes, you may need large capacity slurry pump or high pressure slurry pump. Please click the pictures below to know more:

The Slurry Pump Related You may need more different type of slurry pump for your project like Vertical Sump Slurry pump or submersible slurry pump, sometimes, you may need large capacity slurry pump or high pressure slurry pump. Please click the pictures below to know more:

Please click the contact to send inquiry to us... FAQ Frequently Asked Question for mining separation heavy duty solid slurry pump 1. Q: Are you a trading company or manufacture?

Please click the contact to send inquiry to us... FAQ Frequently Asked Question for mining separation heavy duty solid slurry pump 1. Q: Are you a trading company or manufacture?A: An Pump Machinery Co., Ltd is a real large professional manufacturer since 1982 year, in China, produce with our own factory.

2. Q: what's your factory workshops ?

A: My factory produce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc.

Warmly welcome to visit & test my factory any time.

Click to see the video of An Pump Machinery... Click to see more pictures of An Pump Machinery...

3. Q: How about your slurry pump price?

A: We are sure our price is factory price, and insist high quality for our long term cooperation.

4. Q: What is your slurry pump material ?

A: AM series slurry pump materialhigh Cr Mo Ni alloy, super abrasive-resistant metal.

Shaft & Shaft sleeve material is stainless steel alloy.

5.Q: What kind of liquid can your slurry transfer?

A: Liquid range: water+ sand, solid, sludge, gravel, stones, chemical etc.

6. Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end.

Our factory has 15~30 QC.

7. Q: Is it easy for customers to change the parts by myself ?

A: yes, the structure is simple ,customers can change it very easily. We will also supply you maintenance tools for free.

8. Q: How to do if the pump or parts have operation problem within your warranty?

A: Tell me details timely, and show me pictures, we will send you solution at once without any hesistation.

9. Q: Can you install the electric motor or diesel engine with the pump for us ?

A: yes, we can, it's no problem, we are experienced in this .

10: Q: .we don't know which pump model we need ,can you help us ?

A: yes, please tell me your detail requirements, include liquid, flow rate, head etc,

my engineers teal will calculate & select most suitable pump model for you, offer pump solution for you.

11. Q:How long can you reply us if we send an inquiry ?

A: Generally within 2 hours, we will send you official quotation sheet, with price, technology data, performance curve, dimension etc.

12. Q: How can i contact you ?

A: Contact detail information

Roger Chen

Email: roger @angroupcn.com

Skype: chenroger1215

Tel: 008613780512387 (whatsapp/wechat)

Anything thing need help, please call me any time, i will try best to help you.

Send your inquiry to this supplier

Send Inquiry