1 / 1

Mineral Rotary Drier/Rotary Drum Drier Machine/Small Rotary Drier

Get Latest Price

Send Inquiry

| Model No. : | 1.2*10 |

|---|---|

| Brand Name : | minggong |

Shanghai Minggong Heavy Equipment Co., Ltd.

You might also like

Product description

Specifications 1.used in metallurgy, mining, chemical plant, for drying metal concentrates, tail ore and grain

coal rotary drum dryer

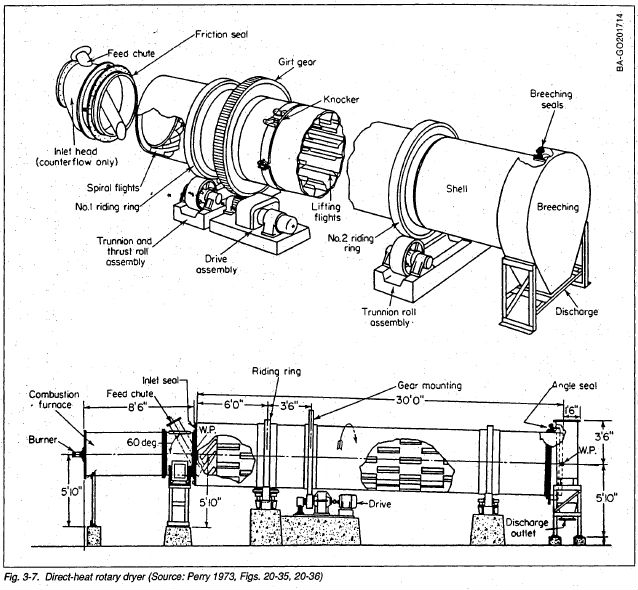

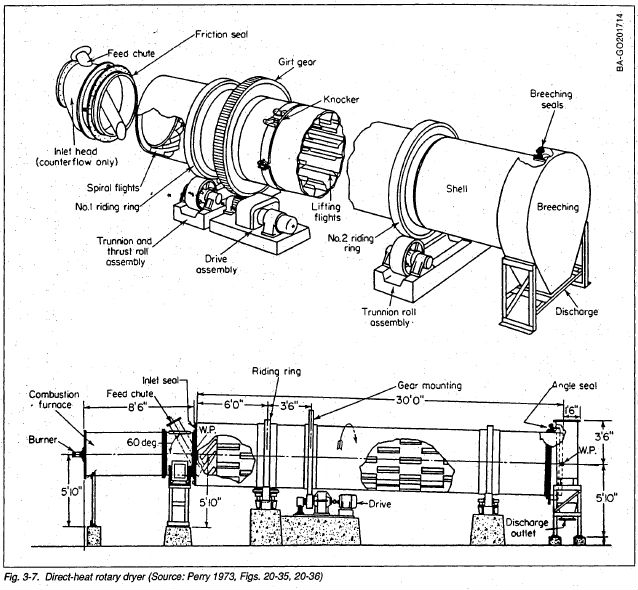

Rotary Dryer Introduction: The so-called rotary drum dryer, also known as rotary drum dryer. It a wide range of applications, mainly used in building materials, metallurgy, chemical and cement industries, and drying of materials limestone slag, coal ash, slag, clay. It mainly consists of the rotary body, lifting plates, transmission device, supporting device and seals and other components. And has a reasonable structure, well-made, high output, low energy consumption, convenient operation. On the other hand, the dryer is a bulky, heavy weight of the laundry facilities, so the machine should be installed on the solid foundation required to maintain the level at the same time to prevent the foundation uneven because the site when installation location equipment work to a larger vibration, thus affecting the life of the washing efficiency and roller dryer.

Rotary Dryer Introduction: The so-called rotary drum dryer, also known as rotary drum dryer. It a wide range of applications, mainly used in building materials, metallurgy, chemical and cement industries, and drying of materials limestone slag, coal ash, slag, clay. It mainly consists of the rotary body, lifting plates, transmission device, supporting device and seals and other components. And has a reasonable structure, well-made, high output, low energy consumption, convenient operation. On the other hand, the dryer is a bulky, heavy weight of the laundry facilities, so the machine should be installed on the solid foundation required to maintain the level at the same time to prevent the foundation uneven because the site when installation location equipment work to a larger vibration, thus affecting the life of the washing efficiency and roller dryer.  Here are suggestions for installing your rotary dryer: 1, when the dryer transport by the manufacturer to your laundry room, you must first dryer routine check, check whether you purchased Which mechanical damage in the transportation process, and can not be used problems should immediately take photographs and contact with manufacturers. 2, before the dryer, you should determine the installation location of the dryer, dryer installation location selection should take into account the transport corridors, raw material turnover, water inlet and the location of the sewer, the male star washing equipment to remind you machine dryer should be installed in the dehydration machine, dryer and other equipment with these devices, reducing the distance, to prevent the inappropriate choice of the location of the subsequent troubles. Reference to the coal slime dryer manual, industrial washing machine in accordance with the instructions to find the electrical control cabinet door access to 380V three-phase power line and the zero line, press the terminal marked (in this case need to be reminded: the electricity consumption of the dryer 380V, prohibit access to low voltage or high voltage) 4, with reference to the dried body tag to the appropriate access to water pipes and steam pipes, such as with steam conditions, the inlet port blocking. Working principle of Rotary Dryer : Rotary Drier mainly consists of revolution body, raise material board, transmission device, supportive device and sealing ring, etc. The heat sources of rotary dryer is from the combustion train, and is adopts down-flow heating methods. When the materials enter into the body from the feeding device, it will be pushed back by the spire raising board. As the rotary dryer is in an inclined position, the materials will be down to the lower end under the influence of gravity and rotation, but the raising board will be threw to the upper end for scattering. This procession makes the material well-distributed in the body, and then ensure the heat exchange with the heat wind. After repeated cycle with this procession, the moisture content will be dried.

Here are suggestions for installing your rotary dryer: 1, when the dryer transport by the manufacturer to your laundry room, you must first dryer routine check, check whether you purchased Which mechanical damage in the transportation process, and can not be used problems should immediately take photographs and contact with manufacturers. 2, before the dryer, you should determine the installation location of the dryer, dryer installation location selection should take into account the transport corridors, raw material turnover, water inlet and the location of the sewer, the male star washing equipment to remind you machine dryer should be installed in the dehydration machine, dryer and other equipment with these devices, reducing the distance, to prevent the inappropriate choice of the location of the subsequent troubles. Reference to the coal slime dryer manual, industrial washing machine in accordance with the instructions to find the electrical control cabinet door access to 380V three-phase power line and the zero line, press the terminal marked (in this case need to be reminded: the electricity consumption of the dryer 380V, prohibit access to low voltage or high voltage) 4, with reference to the dried body tag to the appropriate access to water pipes and steam pipes, such as with steam conditions, the inlet port blocking. Working principle of Rotary Dryer : Rotary Drier mainly consists of revolution body, raise material board, transmission device, supportive device and sealing ring, etc. The heat sources of rotary dryer is from the combustion train, and is adopts down-flow heating methods. When the materials enter into the body from the feeding device, it will be pushed back by the spire raising board. As the rotary dryer is in an inclined position, the materials will be down to the lower end under the influence of gravity and rotation, but the raising board will be threw to the upper end for scattering. This procession makes the material well-distributed in the body, and then ensure the heat exchange with the heat wind. After repeated cycle with this procession, the moisture content will be dried.

Rotary drum dryer features: 1. dryer anti-overload, large capacity, low fuel consumption, low-cost drying. 2, the downstream drying, smoke and wet material from the same side of the dryer, high temperature gas to high evaporation, dryer outlet temperature, high thermal efficiency. 3, according to different material properties to change the operating parameters, so that the material to form a stable full cut fabric curtain in the dryer cylinder body, the quality of heat exchange more fully. 4, the new feeding, nesting devices, put an end to the drum dryer feed plug, discontinuous, uneven, and returning materials such phenomena, reducing the dust load. Drying process needs to consume large amount of heat energy. In order to save energy, some materials with high moisture content, suspending liquid and solution which contain solid objects should be mechanically dewatered or heated first, and then they can be dried in a dryer to get dry solids. During drying process, heat and weight (moisture content) transfer need to be finished simultaneously, thus guaranteeing a higher moisture and water vapor partial pressure inside the dryer than that outside the dryer, and guaranteeing a higher temperature of heat source than that of materials. Technical Data of Rotary Dryer from Shanghai Minggong:

Rotary drum dryer features: 1. dryer anti-overload, large capacity, low fuel consumption, low-cost drying. 2, the downstream drying, smoke and wet material from the same side of the dryer, high temperature gas to high evaporation, dryer outlet temperature, high thermal efficiency. 3, according to different material properties to change the operating parameters, so that the material to form a stable full cut fabric curtain in the dryer cylinder body, the quality of heat exchange more fully. 4, the new feeding, nesting devices, put an end to the drum dryer feed plug, discontinuous, uneven, and returning materials such phenomena, reducing the dust load. Drying process needs to consume large amount of heat energy. In order to save energy, some materials with high moisture content, suspending liquid and solution which contain solid objects should be mechanically dewatered or heated first, and then they can be dried in a dryer to get dry solids. During drying process, heat and weight (moisture content) transfer need to be finished simultaneously, thus guaranteeing a higher moisture and water vapor partial pressure inside the dryer than that outside the dryer, and guaranteeing a higher temperature of heat source than that of materials. Technical Data of Rotary Dryer from Shanghai Minggong:

The process of manufacturing the product:  The main machine in our plant:

The main machine in our plant:  Our product sold to the whole world:

Our product sold to the whole world:  The quality of product guaranteed by below process:

The quality of product guaranteed by below process:

-----About us

coal rotary drum dryer

Rotary Dryer Introduction: The so-called rotary drum dryer, also known as rotary drum dryer. It a wide range of applications, mainly used in building materials, metallurgy, chemical and cement industries, and drying of materials limestone slag, coal ash, slag, clay. It mainly consists of the rotary body, lifting plates, transmission device, supporting device and seals and other components. And has a reasonable structure, well-made, high output, low energy consumption, convenient operation. On the other hand, the dryer is a bulky, heavy weight of the laundry facilities, so the machine should be installed on the solid foundation required to maintain the level at the same time to prevent the foundation uneven because the site when installation location equipment work to a larger vibration, thus affecting the life of the washing efficiency and roller dryer.

Rotary Dryer Introduction: The so-called rotary drum dryer, also known as rotary drum dryer. It a wide range of applications, mainly used in building materials, metallurgy, chemical and cement industries, and drying of materials limestone slag, coal ash, slag, clay. It mainly consists of the rotary body, lifting plates, transmission device, supporting device and seals and other components. And has a reasonable structure, well-made, high output, low energy consumption, convenient operation. On the other hand, the dryer is a bulky, heavy weight of the laundry facilities, so the machine should be installed on the solid foundation required to maintain the level at the same time to prevent the foundation uneven because the site when installation location equipment work to a larger vibration, thus affecting the life of the washing efficiency and roller dryer.  Here are suggestions for installing your rotary dryer: 1, when the dryer transport by the manufacturer to your laundry room, you must first dryer routine check, check whether you purchased Which mechanical damage in the transportation process, and can not be used problems should immediately take photographs and contact with manufacturers. 2, before the dryer, you should determine the installation location of the dryer, dryer installation location selection should take into account the transport corridors, raw material turnover, water inlet and the location of the sewer, the male star washing equipment to remind you machine dryer should be installed in the dehydration machine, dryer and other equipment with these devices, reducing the distance, to prevent the inappropriate choice of the location of the subsequent troubles. Reference to the coal slime dryer manual, industrial washing machine in accordance with the instructions to find the electrical control cabinet door access to 380V three-phase power line and the zero line, press the terminal marked (in this case need to be reminded: the electricity consumption of the dryer 380V, prohibit access to low voltage or high voltage) 4, with reference to the dried body tag to the appropriate access to water pipes and steam pipes, such as with steam conditions, the inlet port blocking. Working principle of Rotary Dryer : Rotary Drier mainly consists of revolution body, raise material board, transmission device, supportive device and sealing ring, etc. The heat sources of rotary dryer is from the combustion train, and is adopts down-flow heating methods. When the materials enter into the body from the feeding device, it will be pushed back by the spire raising board. As the rotary dryer is in an inclined position, the materials will be down to the lower end under the influence of gravity and rotation, but the raising board will be threw to the upper end for scattering. This procession makes the material well-distributed in the body, and then ensure the heat exchange with the heat wind. After repeated cycle with this procession, the moisture content will be dried.

Here are suggestions for installing your rotary dryer: 1, when the dryer transport by the manufacturer to your laundry room, you must first dryer routine check, check whether you purchased Which mechanical damage in the transportation process, and can not be used problems should immediately take photographs and contact with manufacturers. 2, before the dryer, you should determine the installation location of the dryer, dryer installation location selection should take into account the transport corridors, raw material turnover, water inlet and the location of the sewer, the male star washing equipment to remind you machine dryer should be installed in the dehydration machine, dryer and other equipment with these devices, reducing the distance, to prevent the inappropriate choice of the location of the subsequent troubles. Reference to the coal slime dryer manual, industrial washing machine in accordance with the instructions to find the electrical control cabinet door access to 380V three-phase power line and the zero line, press the terminal marked (in this case need to be reminded: the electricity consumption of the dryer 380V, prohibit access to low voltage or high voltage) 4, with reference to the dried body tag to the appropriate access to water pipes and steam pipes, such as with steam conditions, the inlet port blocking. Working principle of Rotary Dryer : Rotary Drier mainly consists of revolution body, raise material board, transmission device, supportive device and sealing ring, etc. The heat sources of rotary dryer is from the combustion train, and is adopts down-flow heating methods. When the materials enter into the body from the feeding device, it will be pushed back by the spire raising board. As the rotary dryer is in an inclined position, the materials will be down to the lower end under the influence of gravity and rotation, but the raising board will be threw to the upper end for scattering. This procession makes the material well-distributed in the body, and then ensure the heat exchange with the heat wind. After repeated cycle with this procession, the moisture content will be dried.

Rotary drum dryer features: 1. dryer anti-overload, large capacity, low fuel consumption, low-cost drying. 2, the downstream drying, smoke and wet material from the same side of the dryer, high temperature gas to high evaporation, dryer outlet temperature, high thermal efficiency. 3, according to different material properties to change the operating parameters, so that the material to form a stable full cut fabric curtain in the dryer cylinder body, the quality of heat exchange more fully. 4, the new feeding, nesting devices, put an end to the drum dryer feed plug, discontinuous, uneven, and returning materials such phenomena, reducing the dust load. Drying process needs to consume large amount of heat energy. In order to save energy, some materials with high moisture content, suspending liquid and solution which contain solid objects should be mechanically dewatered or heated first, and then they can be dried in a dryer to get dry solids. During drying process, heat and weight (moisture content) transfer need to be finished simultaneously, thus guaranteeing a higher moisture and water vapor partial pressure inside the dryer than that outside the dryer, and guaranteeing a higher temperature of heat source than that of materials. Technical Data of Rotary Dryer from Shanghai Minggong:

Rotary drum dryer features: 1. dryer anti-overload, large capacity, low fuel consumption, low-cost drying. 2, the downstream drying, smoke and wet material from the same side of the dryer, high temperature gas to high evaporation, dryer outlet temperature, high thermal efficiency. 3, according to different material properties to change the operating parameters, so that the material to form a stable full cut fabric curtain in the dryer cylinder body, the quality of heat exchange more fully. 4, the new feeding, nesting devices, put an end to the drum dryer feed plug, discontinuous, uneven, and returning materials such phenomena, reducing the dust load. Drying process needs to consume large amount of heat energy. In order to save energy, some materials with high moisture content, suspending liquid and solution which contain solid objects should be mechanically dewatered or heated first, and then they can be dried in a dryer to get dry solids. During drying process, heat and weight (moisture content) transfer need to be finished simultaneously, thus guaranteeing a higher moisture and water vapor partial pressure inside the dryer than that outside the dryer, and guaranteeing a higher temperature of heat source than that of materials. Technical Data of Rotary Dryer from Shanghai Minggong: Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity (%) | Highest Inlet Air Temperature (°C) | Main Motor (kw) | Weight (t) |

Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

The parameters are appr oximate and the actual capacity depends on the material and conditions. For more information please contact Shanghai Minggong. | ||||||

The main machine in our plant:

The main machine in our plant:  Our product sold to the whole world:

Our product sold to the whole world:  The quality of product guaranteed by below process:

The quality of product guaranteed by below process: |

|

|

Our good services:

|

|

The ISO and CE certifacate of our company:

|

| Shanghai Minggong Heavy Equipment CO., LTD is one high-tech enterprise, which involves R&D, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched equipments. |

|  |  |  |

Send your inquiry to this supplier

Send Inquiry