1 / 1

Metform time saving Hole Punching Machine for Angle Steel and BusBar

| Model No. : | Q35Y-16, Q35Y-16 |

|---|---|

| Brand Name : | Metform, metform machinery |

Product description

1.MOQ 1 SET

2.payment FOB Shanghai

3.competitive price

Metform time saving Hole Punching Machine for Angle Steel and BusBar Product Description Noiseless hydraulic Hole Punching Machine for Angle Steel and BusBar Q35Y Series Hydraulic Iron Worker 5 stations ironworker machine Ironworker machine, so called universal shearing machine, is a versatile machine. The Metform’s Hydraulic Iron Worker machines have 5 working stations which are described as below. Punch Large punch bed area, removable front block and quick changing design for punching pin Angle station This station provides large capacity angle cutting at 90° and 45°. Angles between 45° and 90° can be achieved by first cutting at 90° and then flange in the shearing station. Section cutting station For round and square bars, channel, joist, T-sections and may other special profiles. Shearing The shearing unit is fitted with a simple robust hold-down which is adjustable to any thickness of material within the cutting capacity of the machine. Feed table with adjustable guides. Notching station The notching station is fitted as standard with a rectangular notch table with adjustable stops, allowing repetitive positioning. Metform machines are supplied with standard tooling including repetition support tables at punch, Comprehensive safety guards are fitted as standard on all work stations. The hydraulic system is activated by two shielded foot controls for two operator utilization. one operating the punch end cylinder, the other operating the shear end cylinder. The shear cylinder provides the power to the three shearing and the notch stations. Easy for maintenance with centralized lubrication system. Metform Model Q35Y-12, Q35Y-14, Q35Y-16, Q35Y-20, Q35Y-25 and Q35Y-30 are available for cutting different steel size. Main Technical data

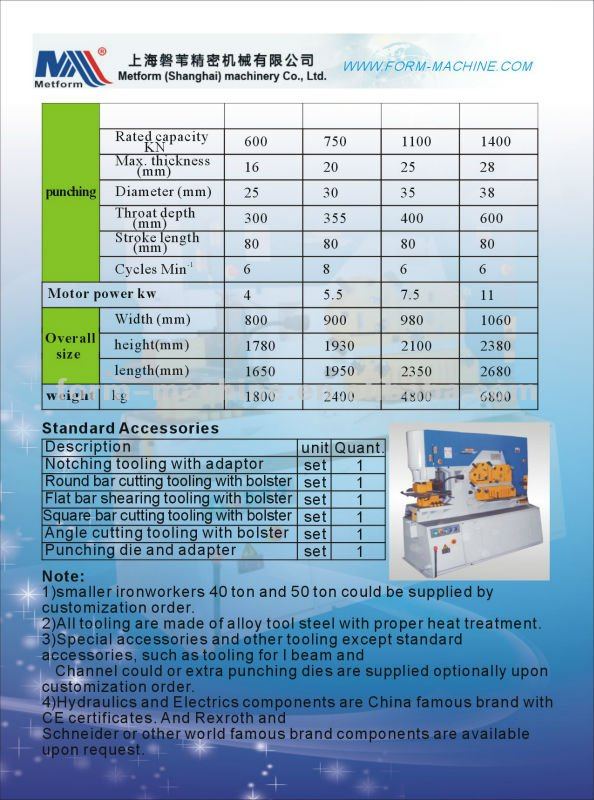

Specification Item | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | |

flat shearing | In max. thickness (mm) | 16*250 | 20*330 | 25*330 | 30*355 |

In max. width(mm) | 8*400 | 10*480 | 16*600 | 20*600 | |

Length of blade(mm) | 400 | 480 | 600 | 600 | |

|

|

|

|

| |

Section cutting | Square (mm) | 40*40 | 45*45 | 50*50 | 55*55 |

Round Dia. (mm) | 45 | 50 | 60 | 65 | |

Channel (mm) | 126*53*5.5 | 160*60*6.5 | 200*75*9 | 280*86*11.5 | |

I beam (mm) | 126*74*5 | 160*86*6 | 200*102*9 | 280*124*10.5 | |

Angle at 90°(mm) | 120*120*12 | 140*140*12 | 160*160*14 | 180*180*16 | |

Notching | Max. thickness (mm) | 10 | 13 | 14 | 16 |

Max. width (mm) | 57 | 57 | 57 | 57 | |

Depth (mm) | 100 | 100 | 100 | 100 | |

punching | Rated capacity KN | 600 | 750 | 1100 | 1400 |

Max. thickness (mm) | 16 | 20 | 25 | 28 | |

Diameter (mm) | 25 | 30 | 35 | 38 | |

Throat depth (mm) | 300 | 355 | 400 | 600 | |

Stroke length (mm) | 80 | 80 | 80 | 80 | |

Cycles Min-1 | 6 | 8 | 6 | 6 | |

|

|

|

|

| |

Motor power kw | 4 | 5.5 | 7.5 | 11 | |

Overall size | Width (mm) | 800 | 900 | 980 | 1060 |

height(mm) | 1780 | 1930 | 2100 | 2380 | |

length(mm) | 1650 | 1950 | 2350 | 2680 | |

weight | kg | 1800 | 2400 | 4800 | 6800 |

Main Products

machinery equipment- seam welding machines, spiral tube forming machines, elbow making machines, roll bending machines, angle steel flat steel volume circle machines, lock formers, hydraulic notching machines, hydraulic combined punching and shearing machine,CNC plasma/laser cutting machine,punch presses, metalworking machines,coil processing machinery, leveling machine,slitting line, cut-to-length lines, rolling mills.

Send your inquiry to this supplier