1 / 6

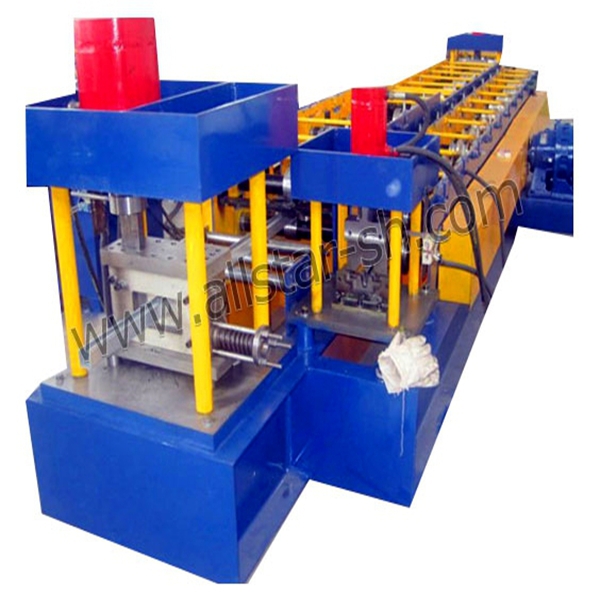

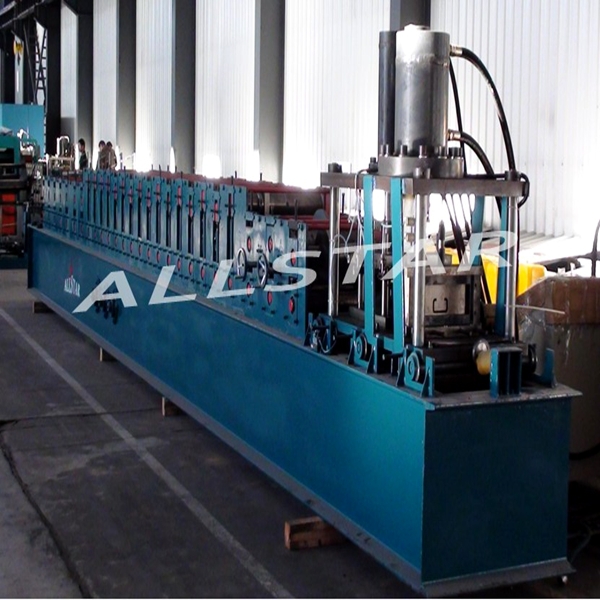

Metal stud roll forming machine, metal stud and track roll forming machine

| Model No. : | ZGM--STR11 |

|---|---|

| Brand Name : | Allstar |

Product description

Product Description A. Main technical parameters

Product Description A. Main technical parameters 1 | Suitable Thickness of Strip Material | 0.2-1.0mm, or as you require |

2 | Roll Forming Speed | 10-15m/min |

3 | Rolling Accuracy | less than ±1mm (in 5m) |

4 | Steps of Main Rollers | 26 steps |

5 | Roller Diameter | 132mm |

6 | Material of Rollers | GCr15, quenched, HRC58-62 |

7 | Material of Shafts | fine 45# steel |

8 | Material of Mould Cutter | Cr12 |

9 | Control System | PLC |

10 | Length Control System | servo motor from Taiwan, accuracy ±0.5mm |

11 | Power of Decelerator Motor | 15KW |

12 | Hydraulic | 8MPa |

13 | Hydraulic Follow Mould Cutting System | hydraulic parts from Taiwan |

14 | Main Electric Components | imported from Taiwan |

15 | Driving System | Cycloid pin wheel decelerator, worm wheel, gimbal drive |

16 | Raw Material | galvanized mild steel |

17 | Power of Hydraulic Motor | 3KW |

Certifications

Certifications  Contacting us Tel: 021-67353838 Fax: 021-57350108 Skype: live:business_949 Add: No.16 Xinshun Road,Zhujing Town Jinshan District Shanghai China.

Contacting us Tel: 021-67353838 Fax: 021-57350108 Skype: live:business_949 Add: No.16 Xinshun Road,Zhujing Town Jinshan District Shanghai China. Send your inquiry to this supplier