1 / 5

Metal Corrugated Sheet Cold Forming Machinery

| Model No. : | ZY |

|---|---|

| Brand Name : | ZHIYE |

| Certification : | ISO |

Cangzhou, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- Trade Company

- OEM service

- Platform Certification

- Video

Product description

Metal Corrugated Sheet Cold Forming Machinery

Production Description

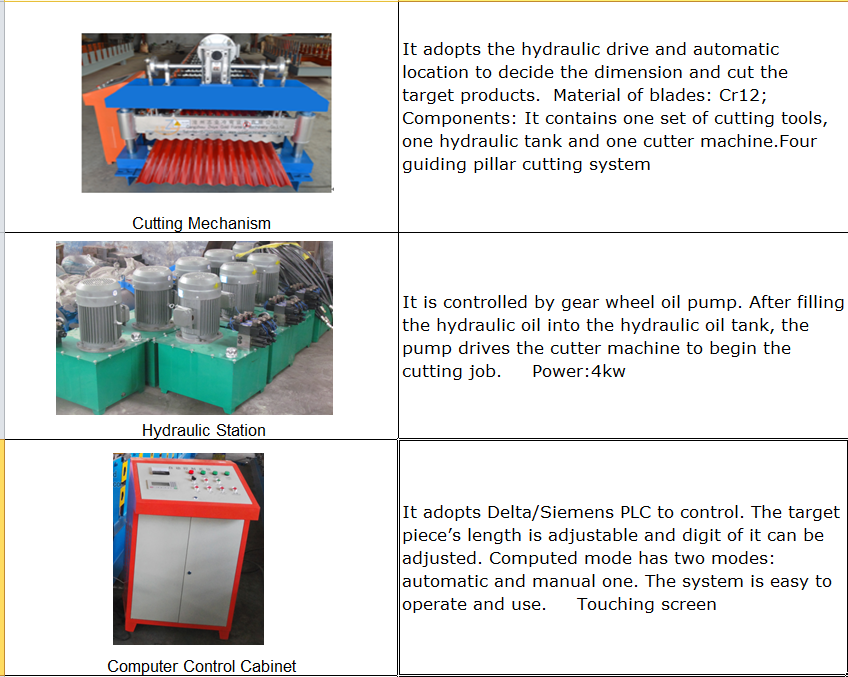

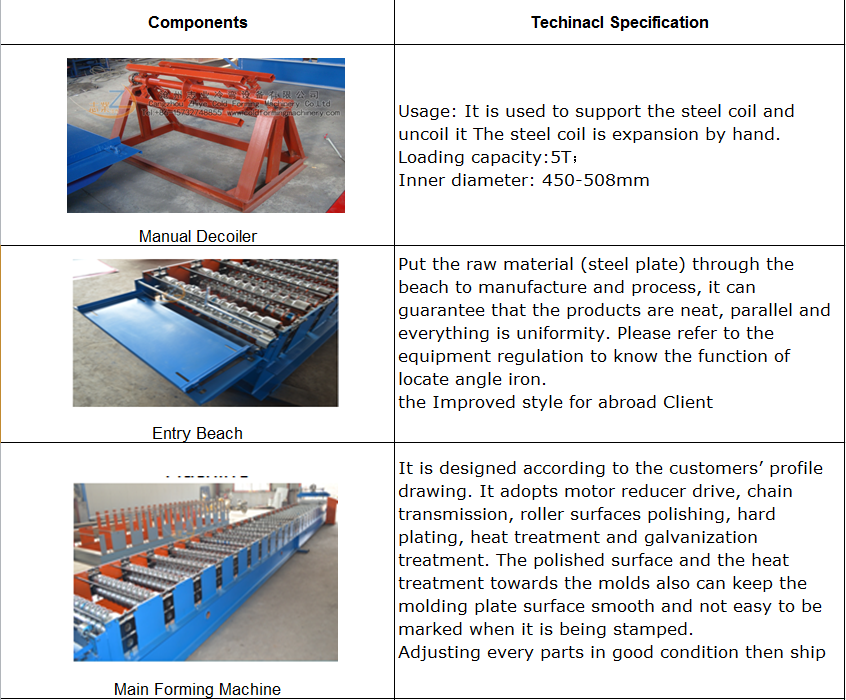

The tiles produced by Metal Corrugated Sheet Cold Forming Machinery are widely used in all kinds of factories, houses, warehouses and simple steel shed, and with beautiful appearance, high efficiency and reliable working.It consists of feeding platform, main molding core, shearing mechanism, hydraulic station, computer control cabinet, high precision counter and so on.

Usage:Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat, parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate angle iron.

Machine Parts Information of the Metal Corrugated Sheet Cold Forming Machinery

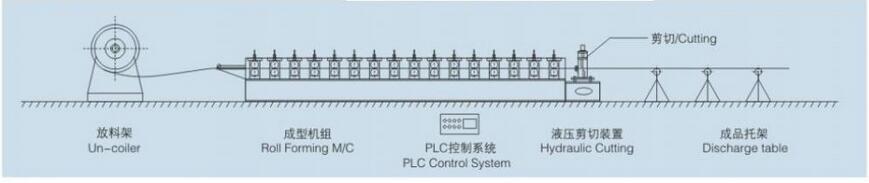

Machine Processing Flow of the Metal Corrugated Sheet Cold Forming Machinery

Machine Specifications and Pictures of the Metal Corrugated Sheet Cold Forming Machinery

Company Information

Cangzhou Zhiye Cold Forming Machinery Co.,Ltd products at large scales have been sold to more than 50 countries and regions, Thailand,India,Malaysia,Turkey,Saudi Arabia, Russia,Albania,Armenia,the United States, Grenada,Bolivia,Colombia,Chile,South africa,Kenya, Tanzania,Egypt and etc, and has won the universal appreciation and commendation from the customers all over the world.

Our Company is the manufacturer specialized in various cold forming machineries and automatic production lines. Main products are: Metal Corrugated Sheet Cold Forming Machinery,Metal Roofing Galvanized Aluminum Sheet Making Machine, C/U/Z purlin roll forming machines, floor decking roll forming machines, steel frame truss roll forming machines, pipe roll forming machines and customerized machines.

Packaging & Shipping

Usually the Corrugated Profile Sheet Roll Forming Machine can be packed into one 20 feet or 40 feet container. we have good relationship wih the shipping agent to get good freight price for you and you can also find yourself at your side.

Our Service

1..Technology R&D

We have R&D centers and innovative designing teams for different kinds of production lines.

2..Quality Control

We have independent QC departments both in the company and factories which strictly control the quality of each process to enable our production lines to reach Chinese National Standards, even International Standards.

3..After Sale Service

Warranty period 2 years , after this period , we are willing to give help if customer needs accessory . The real cooperation will not end at the delivery . we believe that satisfied after sale service means a lot.

4..Inspected by the Sellers

After completing the manufacturing and assembling of the equipments, we will test the machines and commissioning in the workshop.

5..Inspected by the Buyers

After confirmation of a sound work of the line, we will invite our customer to send their representatives to inspect the production lines in our factories.

6..Packing style

Naked but fixed in the container with iron wire to ensure that the machine is kept from colliding;

rust-proof treatment(whole machine covered by plastic film);

spare parts and some small parts shall be packed in boxes.

Our Customers

Contact Information

Cangzhou, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- Trade Company

- OEM service

- Platform Certification

- Video

Send your inquiry to this supplier