1 / 2

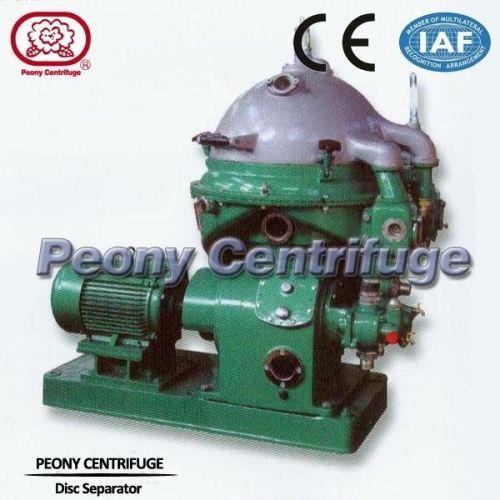

Marine Power Plant Diesel Engine Fuel Oil Handling System Disc Separator 5000 Lph

Product description

Marine Power Plant Diesel Engine Fuel Oil Handling System

Disc Separator 5000 LPH

Decription:

1.Model PDSD5000-H separator is mainly used to remove water and mechanical impurities from fuel oil, lubricating oil and other mineral oil in marine diesel engine unit and land-used diesel generator unit of power station so as to reduce wear of the dieselengine and other machine, and prolong engine life. The model is also used to separate two unsolvable liquids with different specificgravity or remove small amount of solid particle from liquid.

2.The machine adopts automatic control, it has the advantages of high efficiency, low oil consumption, convenient operation and economic maintenance cost.

3.The clear oil and dirty water are pumped out by centripetal pump, the sludge is discharged automatically and fully.

4.The machine is one kind of rotary machine with high speed, After accurate dynamic balancing, it can run for long time with low vibration, safety and security.

5.The design, product and acceptance are conformed to the standard of GB/T5745 “Marine Disc Separator”.

Main technical parameters:

|

Discharging type |

Partial discharge |

|

|

Max capacity |

L/h |

5000 |

|

G-force |

|

7860 |

|

Motor power |

kw |

11 |

|

N.W. |

kg |

1000 |

|

Dimension (L × W × H) |

mm |

1380*900*1477 |

Dimensions:

Consists of:

Condition for mineral oil separation and actual capacity (refer to the chart)

|

Oil types |

Heavy fuel oil |

Lubrication oil |

Steam turbine oil |

|||||

|

SAE30, 40 |

Detergence oil |

|||||||

|

Kinematical viscosity (mm²/s) |

mm²/s(50℃) |

mm²/s(40℃) |

||||||

|

13 |

20.5 |

36.2 |

80 |

100-120 |

65 |

|||

|

Density (kg/m³)(20℃) |

Kg/m³(20℃) |

|

||||||

|

< 900 |

900-991 |

880-900 |

< 900 |

|||||

|

Separating temperature (℃) |

40 |

60 |

80 |

80 |

75 |

|||

|

Recommended capacity (L/h) |

5500 |

5000 |

3000~3250 |

2500~3000 |

1250~1500 |

4000~4250 |

||

|

If you have special requirement, please connect with us. |

||||||||

Value Analysis:

1. Peony adopts SKF bearing , which is consistent with Alfa, Westfalia.

2. Alfa and Westfalia only provide clients with the bearing and the gear in the overhaul package(need to buy separately) while Peony has more sufficient attachment supply.

3. Peony never reduce the amount of spare parts and tools for users buying many sets of the same model machine. (unless the customer put forward in specially).

4. Regular spare parts are all in stock in Peony’s company.

Technical analysis:

Peony's Disc separator technology comparison with foreign companies

|

No. |

Technical Content |

Peony’s Marine Disc Separator |

Oversea famous brand Disc Separator |

|

1 |

The performance index of material |

Viscidity(380 ~700 cSt/50℃) density(1010kg/m3) |

Viscidity(380 ~700 cSt/50℃) density(1010kg/m3) |

|

2 |

Capacity |

1500~8000L/h |

1500~8000L/h |

|

3 |

System integration |

Standardized, modular |

Standardized, modular |

|

4 |

The transmission system |

High-speed flat belt + friction coupling |

High-speed flat belt + friction coupling |

|

5 |

Drum structure |

"No gravity ring" + full hydraulic discharge mode |

"No gravity ring" + full hydraulic discharge mode |

|

6 |

Full automatic control level |

Fulfill online detection, real-time monitoring, intelligent feedback control Meet the requirements of ship with unmanned engine room |

Fulfill online detection, real-time monitoring, intelligent feedback control Meet the requirements of ship with unmanned engine room |

|

7 |

Moisture sensors |

capacitance(the same as Westfalia)

|

capacitance |

|

8 |

Design of calculation method |

Finite element analysis (Structure design and the internal flow field analysis of drum) |

Finite element analysis (Structure design and the internal flow field analysis of drum) |

|

9 |

Drum material |

DSS, Special stainless steel |

DSS, Special stainless steel |

|

10

|

Belt

|

Super seamless ring belt

|

Super seamless ring belt

|

Cost Analysis :

Compared selling price and maintenance cost with Alfa Laval, Westfalia

and other domestic manufacturers

Guarantee:

Peony has advantages in price, service and quality.We have Military Product Quality System Certification, CE certificate,Quality System Certification,many professional equipments and advanced designs.

Principle and structure

Disc separator is vertical centrifuge. The drum is installed on the upper side of the vertical shaft. Driven by the motor, it will rotate at a high speed through the gearing. Inside the drum there is a group of dish parts overlaying each other – disc. There is very small gap between the disc. Suspension (or emulsion) is fed into the drum through the inlet in the middle of the drum. When the suspension (or emulsion) flows through the gap between the disc, under the action of the centrifuge, the solid particles (or droplets) go down to the disc in the formation of sediment (or liquid layer). Along the disc surface, the sediment slides out of the disc and accumulates at the part with the largest diameter inside the drum. After the separation, the liquid is discharge out of the drum from the drain outlet. The role of the disc is to reduce the sediment distance of solid particles (or droplets) and enlarge the sediment area of the drum. With the disc inside the drum, the capacity of the separator is improved greatly. The solid gathering inside the drum is manually removed by taking apart the drum after power off, or discharges from the drum through the slag-off part with the separator power on.

Overviews:

Packing:

Guarantee:

Peony Centrifuge has been dedicated to producing machinery and equipments and carrying out facility construction, pursuing the best quality and producing the best product at the same time.We are committed to reward you with a better quality in return for our interest in and faith toward.We will do our utmost for one more stepping forward, based on our infinite services and trust to customers.

Send your inquiry to this supplier