1 / 5

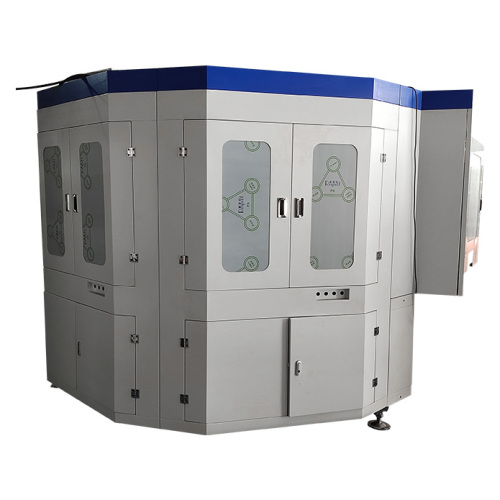

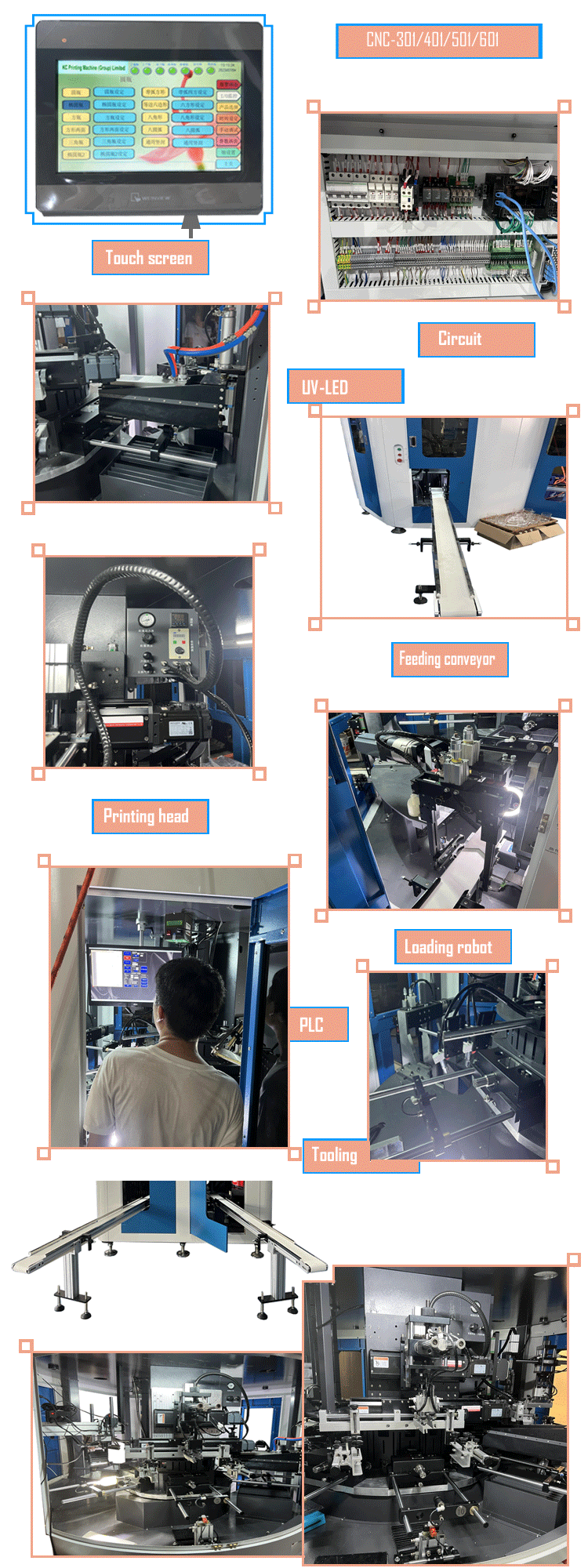

High speed automatic multi fuction screen printing machine

$125000.00

≥1 Set/Sets

Model:

- S-CNC501

| Model No. : | S-CNC501 |

|---|---|

| Brand Name : | KC |

| Applicable industry : | Machinery Repair Shops,Printing Shops,Manufacturing Plant,Food Shop,Retail,Building Material Shops |

Dongguan, Guangdong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- The Belt And Road

Product description

Samples

Description

Description

Specially developed for plastic bottles and glass bottles. After manually placing the bottles on the feeding conveyor belt, the mechanical gripper transfers the bottles to the printing tooling. At the same time, the CCD camera captures the bottom and body of the bottle and cooperates with the servo motor for precise positioning. Two silk printing stations and two colors are completed at the same time. . Then the robot clamps the finished bottle to the unloading line. the

The machine has high efficiency, and the round bottle can reach more than 55 per minute, and the square bottle can reach more than 45 per minute. And the overprinting precision is high, the degree of intelligence is high, and the pass rate of product quality is high.

The main frame of the machine is welded by high-strength and high-quality steel parts, the circular turntable is designed, the main components are processed by CNC, and the plexiglass protective door is installed, which shows the safety of humanization and operation, and meets European safety standards; the control system , Servo motors, electrical components, and pneumatic components are all made of well-known brands from Germany, Japan, and France to ensure the accuracy and stability of the machine's operation. It is suitable for multi-color silk screen printing of round, square, square with arc, oval, rhombus, special-shaped and other bottle shapes.

ITEM

STANDARD ITEMS

Q

1

Feeding system

In-feeding

conveyor with motor-driven

1

Feeding robot

1

2

Pre-treatment

Flame

treatment device

1

3

Workbench

1.5M rotating

workbench with high accurate splitter

1

4

Print system

High accurate

screen printing system

3

Servo screen

plate system

3

Servo

rotating positioning system

3

CCD positioning

system

3

Safety cover

1

PLC Control system

1

5

UV LED system

UV curing

system

3

6

Downloading

Downloading

robot + 1.5M downloading conveyor

1

|

ITEM |

|

STANDARD ITEMS |

Q |

|

1 |

Feeding system |

In-feeding conveyor with motor-driven |

1 |

|

|

|

Feeding robot |

1 |

|

2 |

Pre-treatment |

Flame treatment device |

1 |

|

3 |

Workbench |

1.5M rotating workbench with high accurate splitter |

1 |

|

4 |

Print system |

High accurate screen printing system |

3 |

|

|

|

Servo screen plate system |

3 |

|

|

|

Servo rotating positioning system |

3 |

|

|

|

CCD positioning system |

3 |

|

|

|

Safety cover |

1 |

|

|

|

PLC Control system |

1 |

|

5 |

UV LED system |

UV curing system |

3 |

|

6 |

Downloading |

Downloading robot + 1.5M downloading conveyor |

1 |

Technical parameter:

|

ITEM |

|

Parameters |

Q |

|

1 |

Feeding system |

Speed : 0-10M/ |

|

|

|

|

Conveyor width: 50mm |

|

|

2 |

Pre-treatment |

Fire width: 250mm |

|

|

3 |

Workbench |

Rotating plate diameter : 1.5M |

|

|

4 |

Print system |

Max print diameter: 100mm |

|

|

|

|

Max print length: 300mm |

|

|

|

|

Screen plate up-down adjustment : 150mm |

|

|

|

|

Overprint accurate: 0.05-0.1mm |

|

|

|

|

Max print speed: 3000pcs/H |

|

|

|

|

Air : 5-7 bar |

|

|

|

|

Print color number: 3 colors |

|

|

|

|

Materials: plastics, glass, ceramic,. |

|

|

|

|

PLC Control system |

|

|

5 |

UV system |

UV Wattage: 4KW |

|

|

6 |

Downloading |

Conveyor width : 0.5M |

|

|

|

|

Conveyor speed: 0-10M/min |

|

|

7 |

Power supply |

3 P380V |

|

System Configuration

|

Items |

Description |

Brand |

Note |

|

1 |

Pneumatic components |

SMC , AIRTAC |

Japan, Taiwan |

|

2 |

PLC |

Beckhoff |

Germany |

|

3 |

Light sensor |

Omron/KEYENCE/SICK |

Japan |

|

4 |

Electrical components |

Schneider/Omron |

Germany /Japan |

|

5 |

Splitter |

GOIZPER |

Spanish |

|

6 |

Servo system |

INOVANCE |

China |

Details description

Dongguan, Guangdong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- The Belt And Road

Send your inquiry to this supplier