1 / 6

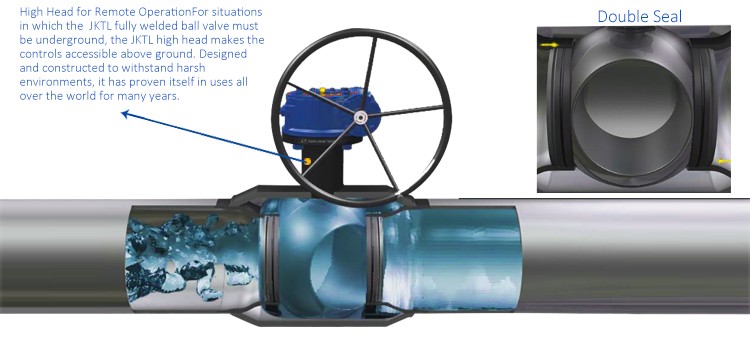

made in china heating system no leak wg ball valve

| Model No. : | ball valve |

|---|---|

| Brand Name : | JINKETONGLI |

Product description

Product Parameter

Product Parameter

Number | Parts | Material |

1 | Valve Body | Steel .DIN St/37.0/37.8 |

2 | Axis Guide | Steel .DIN St/37.0/37.8 |

3 | Valve Ball | Stainless Steel AISI304 |

4 | Stem | Stainless Steel AISI304 |

5 | Ball Valve Seal | Carbon reinforced PTFE |

6 | Body Extension Tube | Steel .DIN St/37.0/37.8 |

7 | Handle | Galvanized Steel |

8 | O-ring/Stem Seal | FPM |

9 | Gasket | PTEF |

Pressure range | ASME/ANSI Class 150 to 2500 |

Temperature range | -20°F to 250°F (-29°C TO 121°C) |

Body | ASTM A350 Gr. LF-2(M) |

End connection | ASTM A350 Gr. LF-2(M) |

Ball | ASTM A694 Gr.F50(M) Chrome plated or ENP |

Seat ring | AISI 1040 |

Seat load spring | AISI 1040 |

Stem seals | PTFE |

Lips | PTFE |

Seat ring insert | Nylon |

The torque stated are for guidance only, they have been obtained by measuring on new ball valve. The torque is to be understood as the pull-off torque applicable for a closed, but recently activated ball valve. The valves stated may rise to a factor of 1.5 after a long period of not being in service.

The torque stated are for guidance only, they have been obtained by measuring on new ball valve. The torque is to be understood as the pull-off torque applicable for a closed, but recently activated ball valve. The valves stated may rise to a factor of 1.5 after a long period of not being in service. Ball valve in fully open position. Medium: water. Density in 1000kg/m3 KVS:

Ball valve in fully open position. Medium: water. Density in 1000kg/m3 KVS: DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

Kv | 7 | 6 | 14 | 26 | 43 | 64 | 100 | 160 | 280 | 450 | 690 | 1100 | 1500 | 2770 |

A×10-4 | 0.79 | 0.79 | 1.77 | 3.14 | 4.9 | 8.04 | 12.56 | 19.63 | 33.18 | 50.27 | 78.54 | 122.72 | 176.71 | 314.16 |

z | 0.32 | 0.44 | 0.41 | 0.37 | 0.33 | 0.4 | 0.4 | 0.39 | 0.36 | 0.32 | 0.33 | 0.32 | 0.35 | 0.33 |

Handle | |

DN15-DN150 | Galvanized Steel |

DN200-DN250 | Spraying carbon steel |

DN250-DN1400 | No handle, using the handwheel |

We recommend DN300-DN1400 manual gearbox operation. | |

Running Condition: | |

temperature -30°C-+200°C(less than 0°C, contact us) | |

Product Advantage

Product Advantage

Certifications

Certifications  Production Process

Production Process  Product Use

Product Use  Contact Us

Contact Us

Send your inquiry to this supplier