1 / 5

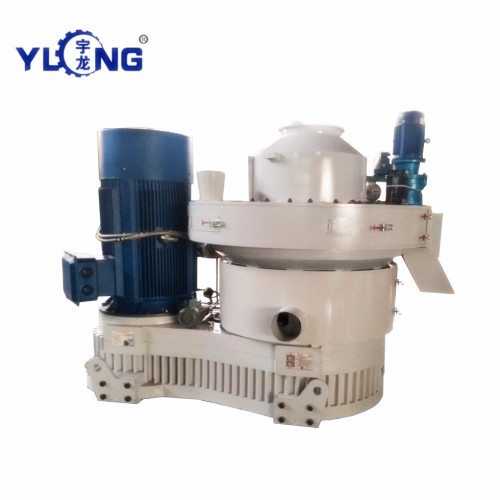

Machinery to Press Wood Pellets

| Model No. : | XGJ850 |

|---|---|

| Brand Name : | YULONG |

| Voltage : | 380V |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Video

Product description

Machinery to Press Wood Pellets XGJ series efficient centrifugal 6mm wood pellet mill is our main product which has adopted the essence of pellet mill in oversea market.The heart parts "double layer die" has unique structural assembly and "rollers" are made of high wearable alloy materials.These two parts have the following characters:particular design,reasonable structure,low energy,high efficiency,long lift and so on.Through many technical experts hard work,our company has developed this typical patent product which comes forth firstly in domestic market.The new machine has filled the country blank in vertical feeding for ring die pellet mill and reached the international advanced level.

Machinery to Press Wood Pellets advantages

1

Double-layer stainless steel ring die, up and down side. One ring die can be using 2 times by turn it over. Reduce operating costs.

2

Vertical ring die, feeding vertically, the raw materials can follow to the pellet machine pelleting room directly.

3

Vertical ring die structure, easy for heating dissipation, which can keep the machine running continually.

4

Ring die fixed, main shaft vertically, main shaft and roller rotating , the roller only can rotating inside of the ring die, so no deflection, no shaking, machine running more stably.

5

Vertical ring die fixed, roller rotating, with centrifugal force, making the materials evenly distributed around inside the die, also the centrifugal force will help improve the capacity.

6

Extremely compact kick-out device, more stable during working.

7

The cover of kick-out device adopt 304 stainless steel, anti-wear and corrosion -resistant.

8

The cover of kick-out device to be pressed one time forming, high strength.

9

Two sets lubrication system--one is lubrication pump to lubricate rollers, the other is lubrication pipe to lubrication main shaft and gear box which ensure the pellet machine can work long time.

10

Thin oil lubrication cooled by air, and equipped with overpressure protection and underpressure alarm, real-time display of circulating pressure, to ensure long-term high load operation of pellet mill.

11

The position of pellet outlet and kick-out reducer can be adjusted according to customers` wishes or factory field situation.

12

The main shaft adopt high stiffness load-bearing structure, diameter increased 15%. And the load-bearing surface of main shaft bearing added 1 time. More stable operation and lower failure rate, aimed to make the pellet machine output higher.

13

The new positioning structure of main shaft supporting frame makes it easier to disassemble the roller and greatly reduces the time for users to replace the roller.

14

The new pressure roller surface adopts the technology of the robot surfacing alloy which extend the service lifetime of the roller.

15

The mould all used high-end wear-resistant stainless steel plus advanced vacuum furnace quenching technology, hardness of surface and inside is the same.

16

The mould hole is machined by ultra-high speed gun drill, and the it can be used after grinding slightly.

Machinery to Press Wood Pellets XGJ series efficient centrifugal 6mm wood pellet mill is our main product which has adopted the essence of pellet mill in oversea market.The heart parts "double layer die" has unique structural assembly and "rollers" are made of high wearable alloy materials.These two parts have the following characters:particular design,reasonable structure,low energy,high efficiency,long lift and so on.Through many technical experts hard work,our company has developed this typical patent product which comes forth firstly in domestic market.The new machine has filled the country blank in vertical feeding for ring die pellet mill and reached the international advanced level.

Machinery to Press Wood Pellets advantages

1

Double-layer stainless steel ring die, up and down side. One ring die can be using 2 times by turn it over. Reduce operating costs.

2

Vertical ring die, feeding vertically, the raw materials can follow to the pellet machine pelleting room directly.

3

Vertical ring die structure, easy for heating dissipation, which can keep the machine running continually.

4

Ring die fixed, main shaft vertically, main shaft and roller rotating , the roller only can rotating inside of the ring die, so no deflection, no shaking, machine running more stably.

5

Vertical ring die fixed, roller rotating, with centrifugal force, making the materials evenly distributed around inside the die, also the centrifugal force will help improve the capacity.

6

Extremely compact kick-out device, more stable during working.

7

The cover of kick-out device adopt 304 stainless steel, anti-wear and corrosion -resistant.

8

The cover of kick-out device to be pressed one time forming, high strength.

9

Two sets lubrication system--one is lubrication pump to lubricate rollers, the other is lubrication pipe to lubrication main shaft and gear box which ensure the pellet machine can work long time.

10

Thin oil lubrication cooled by air, and equipped with overpressure protection and underpressure alarm, real-time display of circulating pressure, to ensure long-term high load operation of pellet mill.

11

The position of pellet outlet and kick-out reducer can be adjusted according to customers` wishes or factory field situation.

12

The main shaft adopt high stiffness load-bearing structure, diameter increased 15%. And the load-bearing surface of main shaft bearing added 1 time. More stable operation and lower failure rate, aimed to make the pellet machine output higher.

13

The new positioning structure of main shaft supporting frame makes it easier to disassemble the roller and greatly reduces the time for users to replace the roller.

14

The new pressure roller surface adopts the technology of the robot surfacing alloy which extend the service lifetime of the roller.

15

The mould all used high-end wear-resistant stainless steel plus advanced vacuum furnace quenching technology, hardness of surface and inside is the same.

16

The mould hole is machined by ultra-high speed gun drill, and the it can be used after grinding slightly.

Machine for pressing biomass pelletsMachinery to Press Wood Pellets Specifications:

|

Model |

Power(kw) |

Capacity(ton/h) |

Weight(ton) |

Dimension(mm) |

|

XGJ560(5th) |

90 |

1-1.5 |

5.3 |

2600*1300*2300 |

|

XGJ850(5th) |

220 |

2-3 |

14.5 |

3300*1400*3100 |

|

XGJ560(7th) |

132 |

1.5-2 |

4.5 |

2588*1250*1602 |

|

XGJ850(7th) |

250 |

3-4 |

13.5 |

2650*1850*2100 |

Machine for pressing biomass pellets manufacture machinery

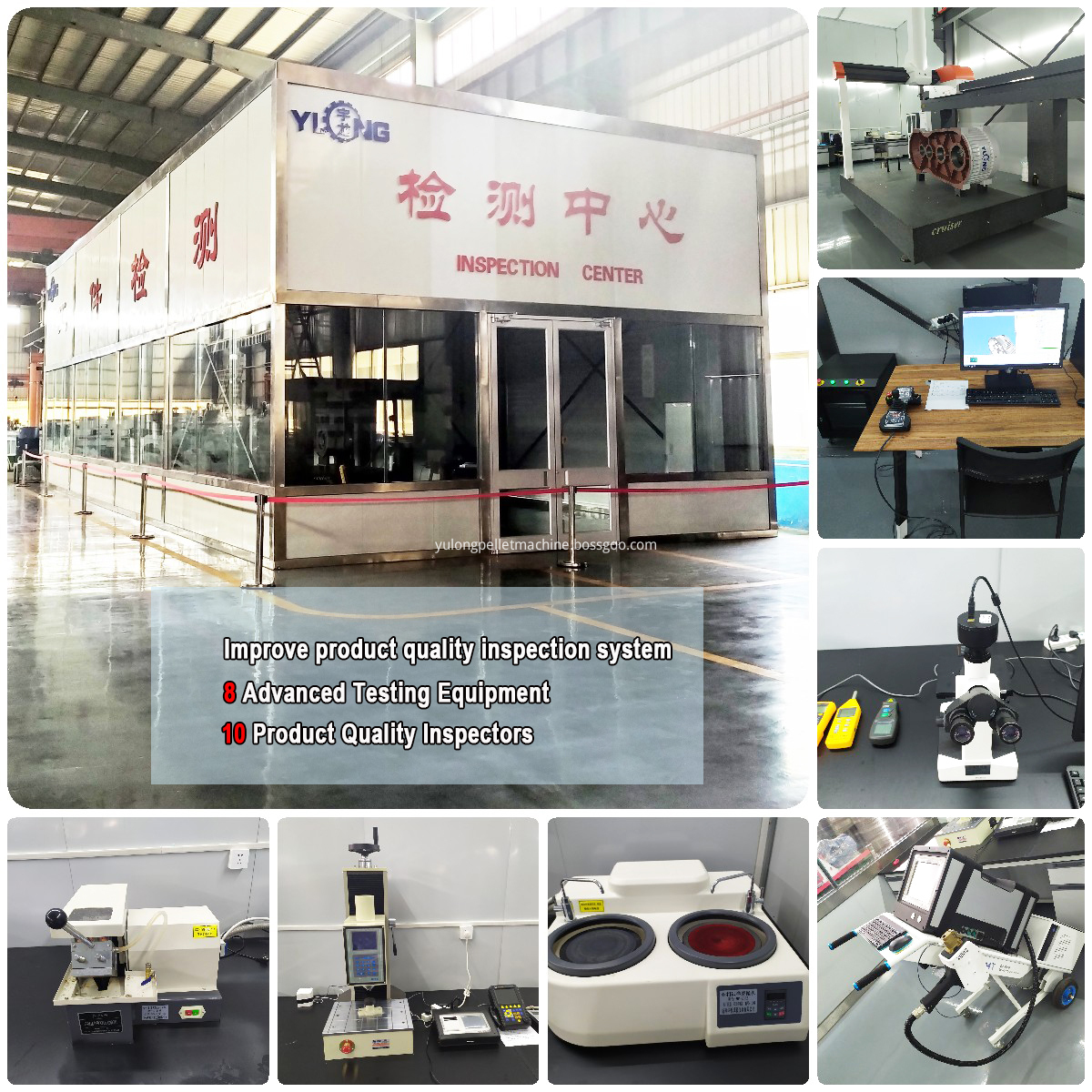

Machinery to Press Wood Pellets YULONG inpection center

Machinery to Press Wood Pellets company

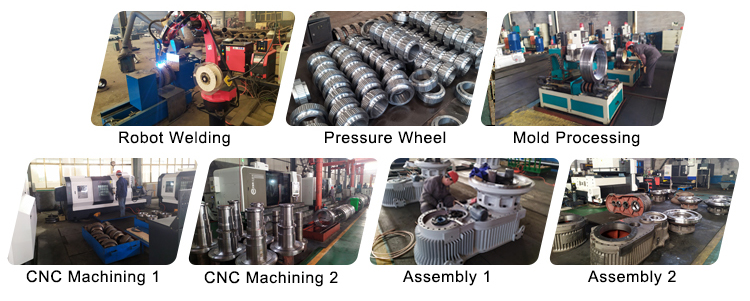

Machinery to Press Wood Pellets strengthen the transmission system

1.Deceleration structure :transmission with parallel shaft three hardened teeth helical slowdown,gear modulus increase,gear widening,strengthening,transmission strength is 3-5 times the conventional reducer.

2.Power input:the use of efficient energy-saving motor,plug directly connected,coaxial high,high-speed shaft with parallel shaft structure,gear shaft are two support rotation,high rigidity,smooth and reliable transmission,to abandon the greater power.

3.Power output:the deice output and the spindle into one,to abandon the limited form of connection,the strength increased 2-3 times.

4.Main shaft strengthening:the shaft length is shortened,the stiffness is significantly improved,high stiffness of the shaft can reduce the wear of mold and rollers.

5.Flexible installation:the device outlet can be multi-angle rotation,equipment installation more flexible and diverse.

Machinery to Press Wood Pellets produce process:

Machine for pressing wood pelletsMachine for pressing biomass pellets

Machine for pressing wood pelletsMachine for pressing biomass pellets

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Video

Send your inquiry to this supplier