1 / 1

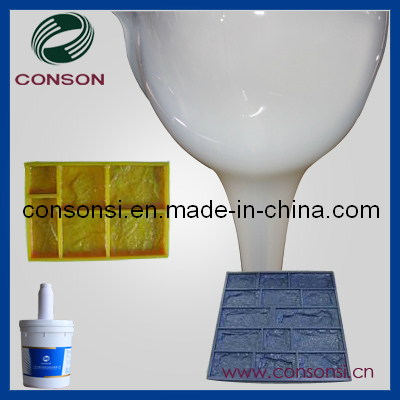

Liquid Silicon Rubber for Stone Moldmaking

Get Latest Price

Send Inquiry

| Model No. : | CSN-8735 |

|---|

Guangzhou Conson Silicone Materials Co., Ltd.

You might also like

Product description

FEATURES:

1. Two-part silicone rubber: Flowable liquid silicone;

2. Cures at room temperature within 1-5 hours;

3. Excellent fluidity and good operability, easy to demold;

4. Good tensile and tear strength, low shrinkage;

5. High temperature resistance;

6. High duplication times.

TECHNICAL GUIDELINES:

1. Stir the liquid silicone (Part A and part B) well before use (except when depending on machine ).

2. This is a 100 Part A to 100 Part B mixing ratio by weight. Weigh the desire amount of part A into a clean mixing container, and then weight the proper amount of part B into the container. Mix the two component together by stirring with a stick. Scrape the container walls and bottom well to insure a thorough mix.

3. Though it is often unnecessary to deair the material due to its low viscosity and our special formulation, it is better to do so to obtain a bubble free rubber. If so, place the container into a vacuum chamber and evacuate the entrapped air from the mixture using a vacuum pump capable of achieving 29 inches of mercury vacuum. The mixture will rise, crest and then collapse in the container. Interruption(bumping) of the vacuum may be necessary to prevent overflowing the container. Keep the mixture under full vacuum for 2-3 minutes.

4. Bleed air slowly into the vacuum chamber. When the chamber is at atmospheric equilibrium, remove the cover plate and take out the container.

5. Pour the deaired material slowly in a steady stream from one end of the mould so that the material flows evenly over the pattern. This should minimize entrapment of air bubbles under the flowing material. A "ready" mold may be poured firstly over the pattern, which will also help reduce the possibility of entrapping air on the pattern and in the cured rubber. A mold release agent may be applied on the pattern first to improve release.

6. Allow the rubber to cure for 2-4 hours at 24C before removing the cured rubber mold from the pattern. Heat acceleration is recommended if necessary.

S series molding silicone rubber, with good operability, high tear strength, no oil migration and excellent chemical resistance, are suitable to make molds for casting of culture stone, sand stone and artificial stone.

1. Two-part silicone rubber: Flowable liquid silicone;

2. Cures at room temperature within 1-5 hours;

3. Excellent fluidity and good operability, easy to demold;

4. Good tensile and tear strength, low shrinkage;

5. High temperature resistance;

6. High duplication times.

TECHNICAL GUIDELINES:

1. Stir the liquid silicone (Part A and part B) well before use (except when depending on machine ).

2. This is a 100 Part A to 100 Part B mixing ratio by weight. Weigh the desire amount of part A into a clean mixing container, and then weight the proper amount of part B into the container. Mix the two component together by stirring with a stick. Scrape the container walls and bottom well to insure a thorough mix.

3. Though it is often unnecessary to deair the material due to its low viscosity and our special formulation, it is better to do so to obtain a bubble free rubber. If so, place the container into a vacuum chamber and evacuate the entrapped air from the mixture using a vacuum pump capable of achieving 29 inches of mercury vacuum. The mixture will rise, crest and then collapse in the container. Interruption(bumping) of the vacuum may be necessary to prevent overflowing the container. Keep the mixture under full vacuum for 2-3 minutes.

4. Bleed air slowly into the vacuum chamber. When the chamber is at atmospheric equilibrium, remove the cover plate and take out the container.

5. Pour the deaired material slowly in a steady stream from one end of the mould so that the material flows evenly over the pattern. This should minimize entrapment of air bubbles under the flowing material. A "ready" mold may be poured firstly over the pattern, which will also help reduce the possibility of entrapping air on the pattern and in the cured rubber. A mold release agent may be applied on the pattern first to improve release.

6. Allow the rubber to cure for 2-4 hours at 24C before removing the cured rubber mold from the pattern. Heat acceleration is recommended if necessary.

S series molding silicone rubber, with good operability, high tear strength, no oil migration and excellent chemical resistance, are suitable to make molds for casting of culture stone, sand stone and artificial stone.

Send your inquiry to this supplier

Send Inquiry