1 / 1

Light Duty Live Center Machine Accessories

| Brand Name : | Qinfeng |

|---|

Product description

Brief introduction

Carbide Light Duty Live Center Machine Accessories, machine tool parts in machining. Tail with a taper shank, installed in the machine tool spindle taper or tailstock shaft hole, with its head against the workpiece cone. Can be used to face the complex parts and do not allow the central hole of the supporting parts. The top is mainly composed of a thimble, a clamping device, a shell, a fixed pin, a bearing and a core shaft. Thimble is the top of the inner hole of the center hole or pipe material, on the other end can be top end is a spherical or conical parts, thimble by the clamping device fixed. When the parts are not allowed or can not hit the central hole, the use of the clamping device to clamp the turning. The shell and the core shaft drill with pin hole, removing of the fixed pin pin or, to achieve the top two. Top can also be used for the work of the drilling, casing and hinge hole.

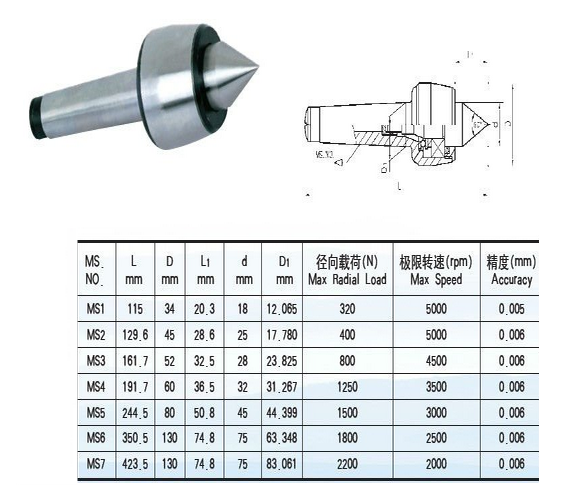

Specifications

1. Light Duty Live Center VPC-MT1,2,3,4,5

2. This live center's accuracy:0.005mm

3. Live live center, High-speed NC live center, Inter-changeable point live center,Lathe center are available.

4. Speed Max:1500~3200r.p.m

| Specification | Length | Diameter | Speed Max |

|

VPC-MT1 |

108 |

32 |

3200r.p.m |

| VPC-MT2 | 132 | 40 | 2800r.p.m |

| VPC-MT3 | 164 | 45 | 2000r.p.m |

| VPC-MT4 | 188 | 48 | 1800r.p.m |

| VPC-MT5 | 248 | 68 |

1500r.p.m |

1. Application and features:

It is an necessary accessory used on medium type lathe for such machine tools as spindle sleeve,tubes and other parts on lathe,locked by center hole.

This product can take big axial load with high precision,and easy operation,spare time and strength reliable performance.

2. Operation steps:A. Clean the taper hole of the tail-stock of the lathe and the shank of center,before putting the shank in the tail stock.

B. Push the tail-stock to clamp the workpiece,if contacting well,lock the tail-stock,then ready for cutting.

C. After finishing cutting,cut off the power,loosen the stock to load down the workpiece.

3. Maintenance:

A.Turn down the nut to grease the bearing by period.

B. If long stored,cleaning ad covering it with oil.

1. Reliable seal design, can prevent dust and cooling liquid penetrate into the interior, head oil hole, the internal bearing oiling maintenance and bearing protection, improve service life.

2. body material: 40Cr forging parts, heat treatment hardness HRC40-42

3. tip axis material: alloy tool steel, heat treatment hardness HRC58-60, with high rigidity and wear resistance.

4. bearing selection: precision cylindrical roller bearings, needle roller bearings.

Send your inquiry to this supplier