1 / 6

LB asphalt mixing plant

Get Latest Price

Send Inquiry

| Model No. : | LB2000, LB-2000 |

|---|---|

| Brand Name : | TAITE |

Wuxi Chiyang International Trading Co., Ltd.

You might also like

Product description

Product Description LB asphalt mixing plant

THE MAIN TECHNICAL CHARACTERISTICS of LB asphalt mixing plant 1.Have compact overall layout and novel structure, absorb advanced technology from Europe, Japan and Italy, perform excellently ; 2.Adopt microcomputer computer system, PLC, module function realize automatic and semi-automatic, manual and single control, real-time dynamic simulation screen display, all-round self trouble diagnosis; 3.Great protection for environmental with low noise because of seal 4.Adopt electronic measurement. Advanced double trechometer way has the function of automatic compensation, high measuring accuracy; 5.The core components are imported , so that the whole equipment is reliable.

THE MAIN TECHNICAL CHARACTERISTICS of LB asphalt mixing plant 1.Have compact overall layout and novel structure, absorb advanced technology from Europe, Japan and Italy, perform excellently ; 2.Adopt microcomputer computer system, PLC, module function realize automatic and semi-automatic, manual and single control, real-time dynamic simulation screen display, all-round self trouble diagnosis; 3.Great protection for environmental with low noise because of seal 4.Adopt electronic measurement. Advanced double trechometer way has the function of automatic compensation, high measuring accuracy; 5.The core components are imported , so that the whole equipment is reliable.

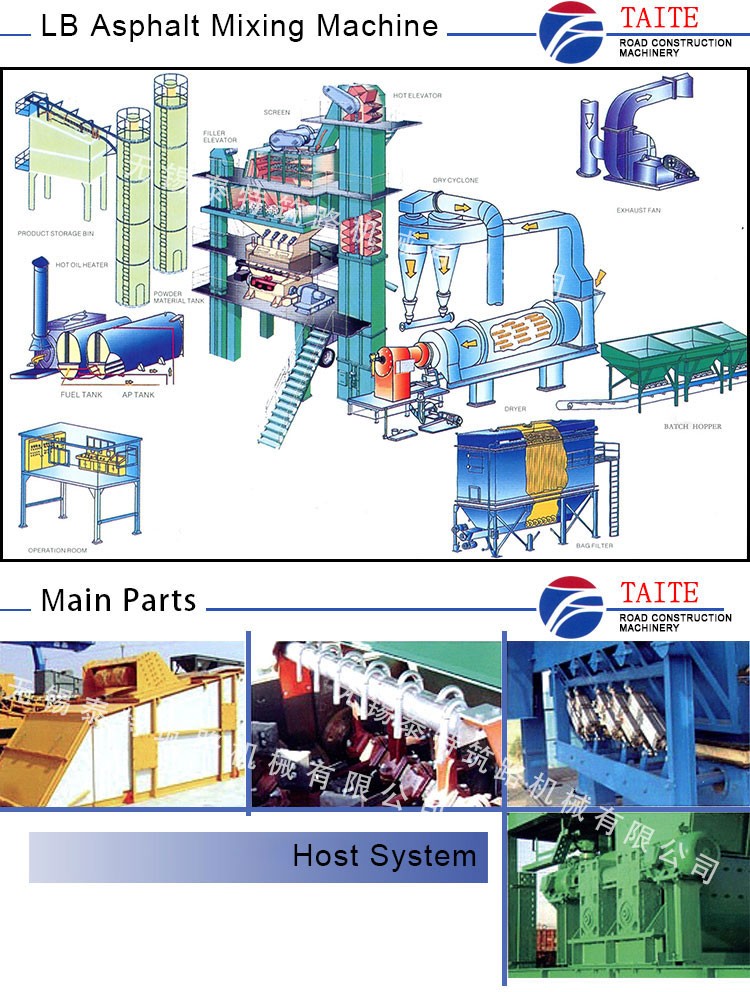

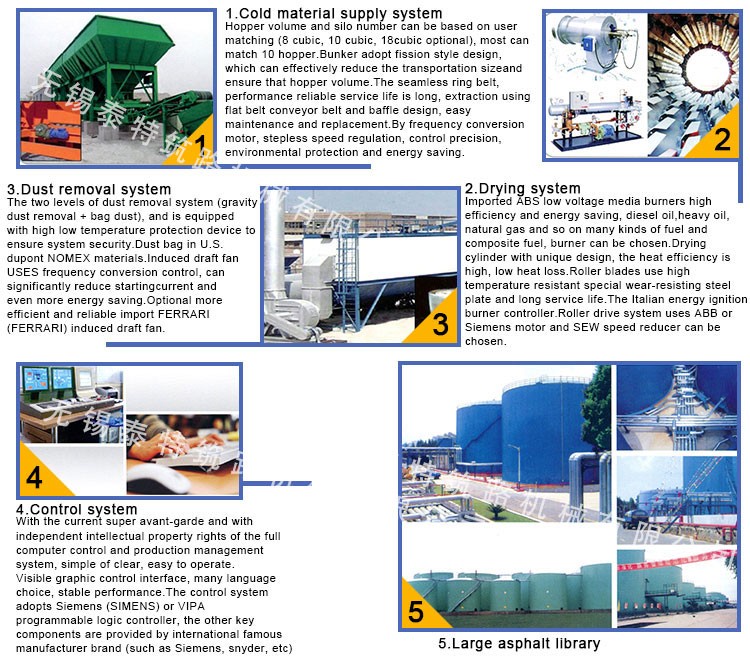

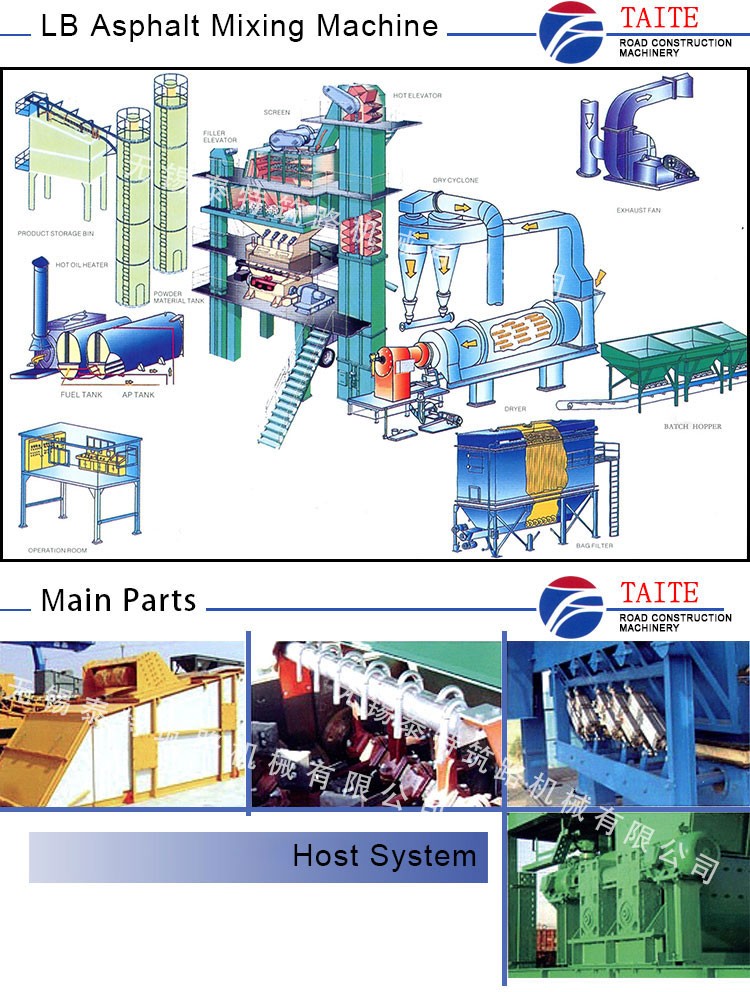

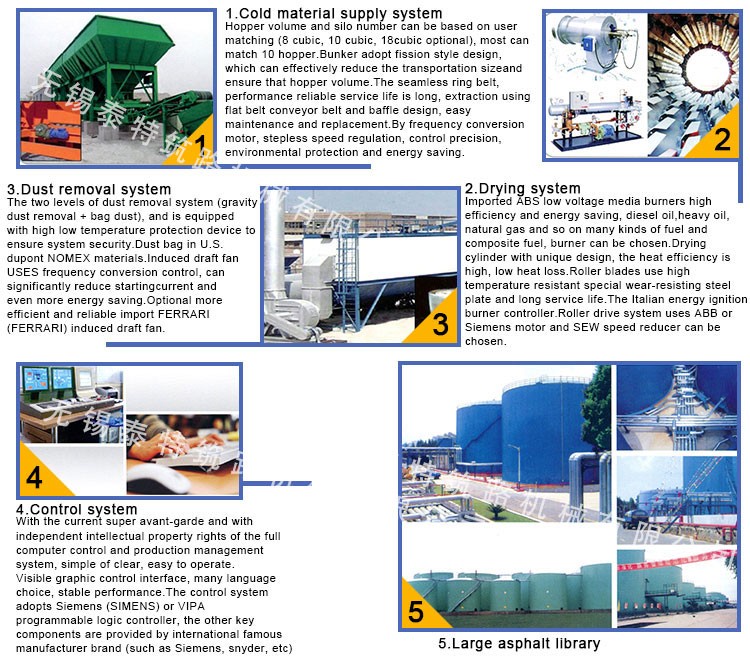

Detailed Information Here are the schematic structure of LB asphalt mixing plant  1.Double board (ring) a chain of bone/powder hoist, reliable performance, convenient maintenance.Vibrating structure design is reasonable, the free maintenance vibration motor startup, convenient to replace sieve net and maintenance.

1.Double board (ring) a chain of bone/powder hoist, reliable performance, convenient maintenance.Vibrating structure design is reasonable, the free maintenance vibration motor startup, convenient to replace sieve net and maintenance.

2.Aggregate door system with double schedule design, which can effectively improve the aggregate measurement precision, and control system itself can be on the error of measurement automatic compensation.

3.Asphalt measurement system using two measurement methods have automatic compensation function, to ensure the accuracy of measurement asphalt and meet the requirements of production ratio.

4.Using two asphalt measurement instrument guarantee the accuracy of the proportion; First set by number of weighing mixture asphalt (usually a little more), spray is according to the actual number of weighing the aggregate according to the right amount of asphalt mixture ratio spray.

5.Through special design of asphalt spray pipe pressure in under the action of the compulsory spray mixing pot, which can effectively reduce the spray time, provide spraying uniformity, and effectively prevent the asphalt falls or drop.

6.Powder measuring system using more small diameter of conveyor for spiral into scales, and by using the variable frequency drive, can significantly improve the accuracy of measurement powder.

7.Each weighing measures (aggregate, powder, asphalt) is equipped with three rumsfeld weighing sensor, stable work, reliable performance.

8.Special design of the dual-axial asphalt concrete mixer, mixing blade arm, leaf and the lining board all use special wear-resisting material, stirring, high efficiency, long life, and at the same time the high speed end ROSSI mechanical synchronous speed reducer,simple structure, low failure rate. Other main parts of LB asphalt mixing plant

Packaging To translate LB asphalt mixing plant, all the components are packaged in the container.

Packaging To translate LB asphalt mixing plant, all the components are packaged in the container. Company Information

Company Information  We are located in the beautiful scenery of the taihu lake, lingshan feet, from the southern jiangsu international airport is very near, south and adjacent the beijing-hangzhou grand canal, west to the 312 national road and beijing-shanghai inter-city high iron, adjacent to the ring taihu highway, the traffic is very convenient, the ground great location; The company is located in the Yangtze river delta region wuxi shuofang airport.lt high-tech industrial park, the region economy active, information quickly, with understanding of the technical support at home and abroad and products supporting ability to build ita mechanical equipment, as a representative of the products, reflects the modern industrial modernization development trend. The company is engaged in earlier domestic build ita the professional production manufacturer of equipment, complete with professional technology and innovation research and development ability, always pay attention to the introduction of foreign advanced new technology, new technology, and has accumulated rich experience in mechanical manufacturing the pavement, the establishment of a scientific management system and perfect testing means, with advanced technology and equipment, strong technical force, the development becomes many varieties, large-scale international competition for professional new technology enterprises. Companies with the first-class products and high quality service, the products sell well all over the country and exported to Mongolia, Indonesia, Bangladesh, Pakistan, Russia and Vietnam and other countries, for countries with international market position.

We are located in the beautiful scenery of the taihu lake, lingshan feet, from the southern jiangsu international airport is very near, south and adjacent the beijing-hangzhou grand canal, west to the 312 national road and beijing-shanghai inter-city high iron, adjacent to the ring taihu highway, the traffic is very convenient, the ground great location; The company is located in the Yangtze river delta region wuxi shuofang airport.lt high-tech industrial park, the region economy active, information quickly, with understanding of the technical support at home and abroad and products supporting ability to build ita mechanical equipment, as a representative of the products, reflects the modern industrial modernization development trend. The company is engaged in earlier domestic build ita the professional production manufacturer of equipment, complete with professional technology and innovation research and development ability, always pay attention to the introduction of foreign advanced new technology, new technology, and has accumulated rich experience in mechanical manufacturing the pavement, the establishment of a scientific management system and perfect testing means, with advanced technology and equipment, strong technical force, the development becomes many varieties, large-scale international competition for professional new technology enterprises. Companies with the first-class products and high quality service, the products sell well all over the country and exported to Mongolia, Indonesia, Bangladesh, Pakistan, Russia and Vietnam and other countries, for countries with international market position.

Related Products Not only LB asphalt mixing plant,but also other features of asphalt mixing plant can we provide.

Related Products Not only LB asphalt mixing plant,but also other features of asphalt mixing plant can we provide. FAQ Q: How about your packing?

FAQ Q: How about your packing?

A.-Standard exporting package. Q: What is your competitiveness? How can I trust your company?

A.-We are professional manufacturer with more than 20years' experience Q: How many days it need to install the concrete batching plant? A: -In general,it takes 2 weeks to install the concrete batching plant. Q: What will be total cycle time-feeding of material,mixing of material,discharging of concrete mix?(we believe that water,admixture,cement & fly ash are also poured parallely while feeding material) A:-The cycle time is 120 seconds. Q: Is PLC fully automatic or semi automatic? A:-PLC can be fully automatic and semi automatic. According to our experience, we recommend fully automatic PLC to you. It is easier to operate fully automatic PLC, thus saving labour cost. Q: Can we see the equipment before order? A:-You are warmly welcome to visit our factory, and our engineers will explain you the machines details one by one. Q: Will you help us to build the factory and install the machine? A:-Yes, our engineers will be sent to your site to help you for the installation. Q:Which payment terms can we accept? A:-Normally we can work on T/T term or L/C term sometimes DP term. 1. On TIT term, 30% down payment is required in advance and 70% balance shall be settled before shipment or against the copy or original B/L for old Client. 2. On LIC term, a 100% Irrevocable L/C without 'soft clauses' can be accepted. Please seek the advice from the individual sales manager whom you work with. Q:How long will our price be valid? A:-we are a tender and friendly supplier, never greedy on windfall profit. Basically, our price remains stable through the year. We only adjust our price eased on two situations: 1.The rate of USD: RMB varies significantly according to the international currency exchange rates. 2.Manufacturers/factories adjusted the machine price because of the increasing labor cost, and raw material cost. Contact Information

THE MAIN TECHNICAL CHARACTERISTICS of LB asphalt mixing plant 1.Have compact overall layout and novel structure, absorb advanced technology from Europe, Japan and Italy, perform excellently ; 2.Adopt microcomputer computer system, PLC, module function realize automatic and semi-automatic, manual and single control, real-time dynamic simulation screen display, all-round self trouble diagnosis; 3.Great protection for environmental with low noise because of seal 4.Adopt electronic measurement. Advanced double trechometer way has the function of automatic compensation, high measuring accuracy; 5.The core components are imported , so that the whole equipment is reliable.

THE MAIN TECHNICAL CHARACTERISTICS of LB asphalt mixing plant 1.Have compact overall layout and novel structure, absorb advanced technology from Europe, Japan and Italy, perform excellently ; 2.Adopt microcomputer computer system, PLC, module function realize automatic and semi-automatic, manual and single control, real-time dynamic simulation screen display, all-round self trouble diagnosis; 3.Great protection for environmental with low noise because of seal 4.Adopt electronic measurement. Advanced double trechometer way has the function of automatic compensation, high measuring accuracy; 5.The core components are imported , so that the whole equipment is reliable. LB Asphalt Mixing Plant Technical Specification | |||||||

| Model | Rated capacity(t/h) | Mixer capacity(kg) | Measurement accuracy | Total power (kw) | Fuel consumption (kg/h) | ||

| Aggregate | Powder | Asphalt | |||||

| LB1000 | 80t/h | 1000kg | ±0.5% | ±0.25% | ±0.2% | 255kw | 6.0kg/h |

| LB1500 | 120t/h | 1500kg | ±0.5% | ±0.25% | ±0.2% | 455kw | 6.0kg/h |

| LB2000 | 160t/h | 2000kg | ±0.5% | ±0.25% | ±0.2% | 510kw | 6.0kg/h |

| LB2500 | 200t/h | 2500kg | ±0.5% | ±0.25% | ±0.2% | 575kw | 6.0kg/h |

| LB3000 | 240t/h | 3000kg | ±0.5% | ±0.25% | ±0.2% | 735kw | 6.0kg/h |

| LB4000 | 320t/h | 4000kg | ±0.5% | ±0.25% | ±0.2% | 890kw | 6.0kg/h |

| LB5000 | 400t/h | 5000kg | ±0.5% | ±0.25% | ±0.2% | 998kw | 6.0kg/h |

| Model | Rated capacity(t/h) | Mixer capacity(kg) | Measurement accuracy | Total power (kw) | Fuel consumption (kg/h) | ||

| Aggregate | Powder | Asphalt | |||||

| GLB2000 | 160t/h | 2000kg | ±0.5% | ±0.25% | ±0.2% | 465kw | 6.0kg/h |

| GLB3000 | 240t/h | 3000kg | ±0.5% | ±0.25% | ±0.2% | 630kw | 6.0kg/h |

| GLB4000 | 320t/h | 4000kg | ±0.5% | ±0.25% | ±0.2% | 790kw | 6.0kg/h |

| Model | Rated capacity(t/h) | Mixer capacity(kg) | Measurement accuracy | Total power (kw) | Fuel consumption (kg/h) | ||

| Aggregate | Powder | Asphalt | |||||

| RLB2000 | 160t/h | 2000kg | ±0.5% | ±0.25% | ±0.2% | 470.5kw | 6.0kg/h |

| RLB3000 | 240t/h | 3000kg | ±0.5% | ±0.25% | ±0.2% | 635.5kw | 6.0kg/h |

1.Double board (ring) a chain of bone/powder hoist, reliable performance, convenient maintenance.Vibrating structure design is reasonable, the free maintenance vibration motor startup, convenient to replace sieve net and maintenance.

1.Double board (ring) a chain of bone/powder hoist, reliable performance, convenient maintenance.Vibrating structure design is reasonable, the free maintenance vibration motor startup, convenient to replace sieve net and maintenance.2.Aggregate door system with double schedule design, which can effectively improve the aggregate measurement precision, and control system itself can be on the error of measurement automatic compensation.

3.Asphalt measurement system using two measurement methods have automatic compensation function, to ensure the accuracy of measurement asphalt and meet the requirements of production ratio.

4.Using two asphalt measurement instrument guarantee the accuracy of the proportion; First set by number of weighing mixture asphalt (usually a little more), spray is according to the actual number of weighing the aggregate according to the right amount of asphalt mixture ratio spray.

5.Through special design of asphalt spray pipe pressure in under the action of the compulsory spray mixing pot, which can effectively reduce the spray time, provide spraying uniformity, and effectively prevent the asphalt falls or drop.

6.Powder measuring system using more small diameter of conveyor for spiral into scales, and by using the variable frequency drive, can significantly improve the accuracy of measurement powder.

7.Each weighing measures (aggregate, powder, asphalt) is equipped with three rumsfeld weighing sensor, stable work, reliable performance.

8.Special design of the dual-axial asphalt concrete mixer, mixing blade arm, leaf and the lining board all use special wear-resisting material, stirring, high efficiency, long life, and at the same time the high speed end ROSSI mechanical synchronous speed reducer,simple structure, low failure rate. Other main parts of LB asphalt mixing plant

Packaging To translate LB asphalt mixing plant, all the components are packaged in the container.

Packaging To translate LB asphalt mixing plant, all the components are packaged in the container. Company Information

Company Information  We are located in the beautiful scenery of the taihu lake, lingshan feet, from the southern jiangsu international airport is very near, south and adjacent the beijing-hangzhou grand canal, west to the 312 national road and beijing-shanghai inter-city high iron, adjacent to the ring taihu highway, the traffic is very convenient, the ground great location; The company is located in the Yangtze river delta region wuxi shuofang airport.lt high-tech industrial park, the region economy active, information quickly, with understanding of the technical support at home and abroad and products supporting ability to build ita mechanical equipment, as a representative of the products, reflects the modern industrial modernization development trend. The company is engaged in earlier domestic build ita the professional production manufacturer of equipment, complete with professional technology and innovation research and development ability, always pay attention to the introduction of foreign advanced new technology, new technology, and has accumulated rich experience in mechanical manufacturing the pavement, the establishment of a scientific management system and perfect testing means, with advanced technology and equipment, strong technical force, the development becomes many varieties, large-scale international competition for professional new technology enterprises. Companies with the first-class products and high quality service, the products sell well all over the country and exported to Mongolia, Indonesia, Bangladesh, Pakistan, Russia and Vietnam and other countries, for countries with international market position.

We are located in the beautiful scenery of the taihu lake, lingshan feet, from the southern jiangsu international airport is very near, south and adjacent the beijing-hangzhou grand canal, west to the 312 national road and beijing-shanghai inter-city high iron, adjacent to the ring taihu highway, the traffic is very convenient, the ground great location; The company is located in the Yangtze river delta region wuxi shuofang airport.lt high-tech industrial park, the region economy active, information quickly, with understanding of the technical support at home and abroad and products supporting ability to build ita mechanical equipment, as a representative of the products, reflects the modern industrial modernization development trend. The company is engaged in earlier domestic build ita the professional production manufacturer of equipment, complete with professional technology and innovation research and development ability, always pay attention to the introduction of foreign advanced new technology, new technology, and has accumulated rich experience in mechanical manufacturing the pavement, the establishment of a scientific management system and perfect testing means, with advanced technology and equipment, strong technical force, the development becomes many varieties, large-scale international competition for professional new technology enterprises. Companies with the first-class products and high quality service, the products sell well all over the country and exported to Mongolia, Indonesia, Bangladesh, Pakistan, Russia and Vietnam and other countries, for countries with international market position.

Related Products Not only LB asphalt mixing plant,but also other features of asphalt mixing plant can we provide.

Related Products Not only LB asphalt mixing plant,but also other features of asphalt mixing plant can we provide. FAQ Q: How about your packing?

FAQ Q: How about your packing?A.-Standard exporting package. Q: What is your competitiveness? How can I trust your company?

A.-We are professional manufacturer with more than 20years' experience Q: How many days it need to install the concrete batching plant? A: -In general,it takes 2 weeks to install the concrete batching plant. Q: What will be total cycle time-feeding of material,mixing of material,discharging of concrete mix?(we believe that water,admixture,cement & fly ash are also poured parallely while feeding material) A:-The cycle time is 120 seconds. Q: Is PLC fully automatic or semi automatic? A:-PLC can be fully automatic and semi automatic. According to our experience, we recommend fully automatic PLC to you. It is easier to operate fully automatic PLC, thus saving labour cost. Q: Can we see the equipment before order? A:-You are warmly welcome to visit our factory, and our engineers will explain you the machines details one by one. Q: Will you help us to build the factory and install the machine? A:-Yes, our engineers will be sent to your site to help you for the installation. Q:Which payment terms can we accept? A:-Normally we can work on T/T term or L/C term sometimes DP term. 1. On TIT term, 30% down payment is required in advance and 70% balance shall be settled before shipment or against the copy or original B/L for old Client. 2. On LIC term, a 100% Irrevocable L/C without 'soft clauses' can be accepted. Please seek the advice from the individual sales manager whom you work with. Q:How long will our price be valid? A:-we are a tender and friendly supplier, never greedy on windfall profit. Basically, our price remains stable through the year. We only adjust our price eased on two situations: 1.The rate of USD: RMB varies significantly according to the international currency exchange rates. 2.Manufacturers/factories adjusted the machine price because of the increasing labor cost, and raw material cost. Contact Information

Send your inquiry to this supplier

Send Inquiry