1 / 4

Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill

Get Latest Price

Send Inquiry

| Model No. : | vertical milling machine |

|---|---|

| Brand Name : | Zenith |

Shanghai Zenith Mining And Construction Machinery Co., Ltd.

You might also like

Product description

How to quickly understand Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill ? LUM series ultrafine vertical roller mill is my company combined with grinding machine production experience for many years, on the basis of common vertical mill, roller technology using the latest Taiwan and Germany choose powder technology, independent design and development of new type of superfine grinding equipment.Superfine grinding, classification, transmission in the integration of ultrafine vertical mill, has become the first choice of superfine powder industry.LUM series ultrafine vertical roller mill is widely used in cement, building materials, electric power, metallurgy, chemical industry, non-metallic mineral industries such as all kinds of solid materials grinding and super finely grinding process.

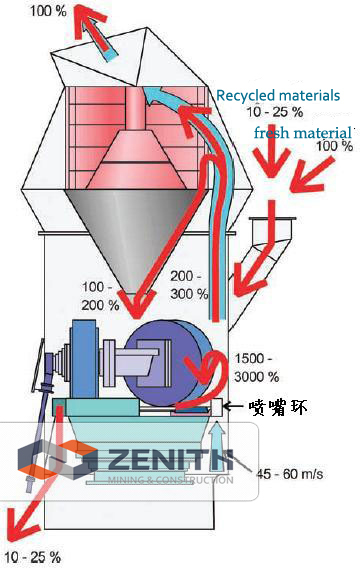

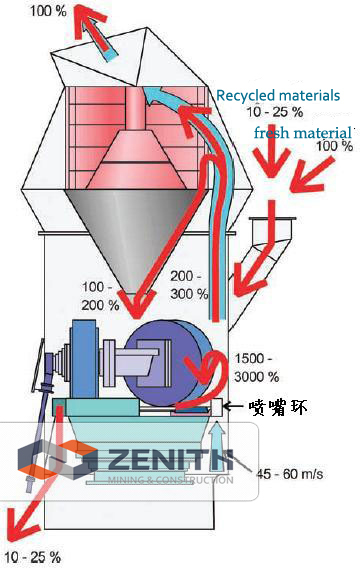

Parts classification( If you already have grinding mill,zenith provide a variety of accessories ) How to work the Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill? Driven by the main motor reducer rotating disc, while wind from the inlet into the LUM superfine vertical mill, the material through the screw feeder to feed port falls under the central disc, the centrifugal force, the material evenly from the center to the edge of the disc moving through the area when the grinding disc on the roller by rolling mill rolls, bulk materials directly crushed fine material formed by extrusion material bed after the inter-particle crushing.

Parts classification( If you already have grinding mill,zenith provide a variety of accessories ) How to work the Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill? Driven by the main motor reducer rotating disc, while wind from the inlet into the LUM superfine vertical mill, the material through the screw feeder to feed port falls under the central disc, the centrifugal force, the material evenly from the center to the edge of the disc moving through the area when the grinding disc on the roller by rolling mill rolls, bulk materials directly crushed fine material formed by extrusion material bed after the inter-particle crushing.

Crushed material to the disc edge continues to move until it is taken at the air ring strong airflow, while larger particles of material to fall again on the disc to continue grinding material flow through the upper portion of the separator, the rotor under the action of the blade, coarse particles back on disc grinding, qualified powder together with the air out of grinding, is collected powder collector system, are collected into a vertical mill ultrafine powder is milled products. When mixed with the material of iron and other debris material moves to the edge of the disc, which can not be due to the large windblown own weight, falling to the mill to be installed at the bottom of the lower chamber of the disc scraper plate scraped into the slag discharge port outside the machine. Why choose zenith Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill ? 1.low investment cost, the machine set crushing, drying, grinding, sorting conveyor at an organic whole, the system is simple, layout is compact, cover an area of an area small, and can be open to decorate, a lot of lower investment cost.

Why choose zenith Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill ? 1.low investment cost, the machine set crushing, drying, grinding, sorting conveyor at an organic whole, the system is simple, layout is compact, cover an area of an area small, and can be open to decorate, a lot of lower investment cost.

2.high grinding efficiency, the grinding roll on direct rolling mill grinding materials, low energy consumption, and the ball mill system compares and economizes 30% of energy

1.LUM has excellent grinding-efficiency for the special design of roller shell and grinding plate curve.

2.Low investment cost: LUM use PLC/DCS automatic control system, well save the cost of operators.

3.Utilize advanced working principle and reduce the grinding time, as a result, the final products has little iron and the whiteness and purity are raised.

4.LUM is of little dust and noise, achieving Environmental Protection Request, it is quite environmentally friendly. consumption - 40%.

3.drying ability: this machine USES the hot gas conveying material, therefore, in the grinding machine can dry grinding water up to 15% of the material, saves raw material drying system, and by adjusting the hot blast temperature, meet different humidity material requirements.

4.product quality is stable, because the material stay in the grinding time is short, easy to detect and control the product particle size and chemical composition, reduce duplication of grinding, stable product quality, is used for grinding white or transparent materials, high whiteness and clarity of the product. Which kinds of Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill is more suitable for you? LUM Ultrafine Vertical Roller Mill

tips: Too many models, only lists the main products!

The production capacity>0.4t/h,Our machine all can be used! Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill price? 1.Different models, different prices; 2. Message of reply, I will immediately report to you the price! what is the raw material do you want to process?

what is the capacity per hour do you need? what is the raw material input size?

what is the output size of your product? 3.Reply message can get 5% discount! Production Line Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Products and Capacity:

5-500ton per hour crushing equipments and milling equipments Covers:

jaw crusher, impact crusher, double roller crusher, hammer crusher, vertical combination crusher, cone crusher; ball mill, coal mill, ceramic ball mill, cement ball mill, rod mill

10-200ton per hour Mineral processing equipments Covers:

spiral classifier, agitating tank, flotation machine, magnetic separator, shaking table, spiral chute, jig separator, high frequency screen, rotary kiln, thickener, belt conveyor, feeder

10-500ton per hour artificial stone and sand production line equipments Covers:

vibrating feeder, jaw crusher, impact crusher, vibrating screen, dust catcher, belt conveyor, ball mill, sand making machine, sand washing machine, rotary dryer zenith production line of cases in various countries (Jeddah;Brunei;Angola;UAE;Palestine;Mexico;Kenya;Ghana;INDIA;KSA; Oman;Egypt;Indonesia; Etc.) zenith all kinds of aggregate plant( Basalt;Granite;Feldspar;River Stone;Limestone;Iron Ore;Dolomite;Calcite;Gypsum;Gold; Bauxite;Copper;Construction Waste;Etc.) Packaging & Shipping About the logistics 1.Choose the most efficient logistics company; 2. Port in Shanghai, convenient transportation, lead in all directions; 3. Transport packaging is rigorous, accessories in the wooden box; 4. If there is a problem of logistics, can leave a message.

Packaging & Shipping About the logistics 1.Choose the most efficient logistics company; 2. Port in Shanghai, convenient transportation, lead in all directions; 3. Transport packaging is rigorous, accessories in the wooden box; 4. If there is a problem of logistics, can leave a message.  zenith products sales site distribution map

zenith products sales site distribution map  Company Information Shanghai Zenith Mining and Construction Machinery Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices.

Company Information Shanghai Zenith Mining and Construction Machinery Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices.

Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future. We hold "Pursuing the Zenith Technology and Quality" as our management concept all the time.

Relying on absorbing world leading crushing and powder processing technology, advanced management and quality control system, as well as our full efforts, ZENITH has earned high reputation among our customers. Factory picture Headquarter of Zenith is located in Shanghai, China and now we have two manufacturing bases as our strong support.

One is located in Shanghai about 450,000 square meters, and the other is in Qidong city, about 600,000 square meters. It takes about one-hour driving from Shanghai to Qidong city. Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry. With the development of our ZENITH, we would like to help more and more customers start their business in mining and construction industries, offer them the best solution, much more advanced machinery and better service. Our Services We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience. We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience. Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Pre-sales Service:

Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit zenith working machines or complete plant in the site. To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc. Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also. After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of Zenith, they are now strategically located home and abroad, working for our customers. Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Technological support:

New products development is a key part of Zenith culture since it was founded. Zenith R&D team is made of 78 senior engineers. The top seven engineers are winners of special central government allowance, which are for the outstanding contribution in science and technology. They are good at not only principle of mechanics, but also integration of theory and practical feedback, based on this they give solid support to our sales. Depending on our national patent machines such as XZM ultrafine mill, MTM mill, B Series Deep Rotor Vertical Shaft Impact Crusher, etc., Zenith win good reputation from markets home and abroad. Recent development includes the MTW series mill, vertical mill, Hydraulic impact crusher,Track mounted crusher, PEW series jaw crusher, etc. Deeply believe that the measure of our worth is in the development and innovation of new products, and we are pursuing the “Zenith direction of technology and quality” all the way. FAQ We have more than 100 kinds of products, there is always a right for you! If you are new for this business: Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry. 1.What is the type and size of raw material? 2.What is your required capacity(t/h)? 3.what is the raw material input size? 4.what is the output size of your product? Look forward to your inquiries! ....

We have more than 100 kinds of products, there is always a right for you! If you are new for this business: Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry. 1.What is the type and size of raw material? 2.What is your required capacity(t/h)? 3.what is the raw material input size? 4.what is the output size of your product? Look forward to your inquiries! ....

Parts classification( If you already have grinding mill,zenith provide a variety of accessories ) How to work the Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill? Driven by the main motor reducer rotating disc, while wind from the inlet into the LUM superfine vertical mill, the material through the screw feeder to feed port falls under the central disc, the centrifugal force, the material evenly from the center to the edge of the disc moving through the area when the grinding disc on the roller by rolling mill rolls, bulk materials directly crushed fine material formed by extrusion material bed after the inter-particle crushing.

Parts classification( If you already have grinding mill,zenith provide a variety of accessories ) How to work the Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill? Driven by the main motor reducer rotating disc, while wind from the inlet into the LUM superfine vertical mill, the material through the screw feeder to feed port falls under the central disc, the centrifugal force, the material evenly from the center to the edge of the disc moving through the area when the grinding disc on the roller by rolling mill rolls, bulk materials directly crushed fine material formed by extrusion material bed after the inter-particle crushing.Crushed material to the disc edge continues to move until it is taken at the air ring strong airflow, while larger particles of material to fall again on the disc to continue grinding material flow through the upper portion of the separator, the rotor under the action of the blade, coarse particles back on disc grinding, qualified powder together with the air out of grinding, is collected powder collector system, are collected into a vertical mill ultrafine powder is milled products. When mixed with the material of iron and other debris material moves to the edge of the disc, which can not be due to the large windblown own weight, falling to the mill to be installed at the bottom of the lower chamber of the disc scraper plate scraped into the slag discharge port outside the machine.

Why choose zenith Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill ? 1.low investment cost, the machine set crushing, drying, grinding, sorting conveyor at an organic whole, the system is simple, layout is compact, cover an area of an area small, and can be open to decorate, a lot of lower investment cost.

Why choose zenith Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill ? 1.low investment cost, the machine set crushing, drying, grinding, sorting conveyor at an organic whole, the system is simple, layout is compact, cover an area of an area small, and can be open to decorate, a lot of lower investment cost.2.high grinding efficiency, the grinding roll on direct rolling mill grinding materials, low energy consumption, and the ball mill system compares and economizes 30% of energy

1.LUM has excellent grinding-efficiency for the special design of roller shell and grinding plate curve.

2.Low investment cost: LUM use PLC/DCS automatic control system, well save the cost of operators.

3.Utilize advanced working principle and reduce the grinding time, as a result, the final products has little iron and the whiteness and purity are raised.

4.LUM is of little dust and noise, achieving Environmental Protection Request, it is quite environmentally friendly. consumption - 40%.

3.drying ability: this machine USES the hot gas conveying material, therefore, in the grinding machine can dry grinding water up to 15% of the material, saves raw material drying system, and by adjusting the hot blast temperature, meet different humidity material requirements.

4.product quality is stable, because the material stay in the grinding time is short, easy to detect and control the product particle size and chemical composition, reduce duplication of grinding, stable product quality, is used for grinding white or transparent materials, high whiteness and clarity of the product. Which kinds of Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill is more suitable for you? LUM Ultrafine Vertical Roller Mill

| Model | LUM1125 | LUM1232 | LUM1436 |

| Wheel diameter(mm) | 1100 | 1200 | 1400 |

| Capacity (t/h) | 5~12 | 7~16 | 8~18 |

| Fineness 400~650Mesh | ~D97 | ~D97 | ~D97 |

| Material Size(mm) | <10 | < 10 | <10 |

| Moisture | <3% | <3% | <3% |

| Main Motor Power(KW) | 250 | 315 | 355 |

| Roller(set) | 3 | 3 | 3 |

| Classifier Motor Power | 15 KWx5 | 15 KWx7 | 15 KWx7 |

The production capacity>0.4t/h,Our machine all can be used! Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill price? 1.Different models, different prices; 2. Message of reply, I will immediately report to you the price! what is the raw material do you want to process?

what is the capacity per hour do you need? what is the raw material input size?

what is the output size of your product? 3.Reply message can get 5% discount! Production Line Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Products and Capacity:

5-500ton per hour crushing equipments and milling equipments Covers:

jaw crusher, impact crusher, double roller crusher, hammer crusher, vertical combination crusher, cone crusher; ball mill, coal mill, ceramic ball mill, cement ball mill, rod mill

10-200ton per hour Mineral processing equipments Covers:

spiral classifier, agitating tank, flotation machine, magnetic separator, shaking table, spiral chute, jig separator, high frequency screen, rotary kiln, thickener, belt conveyor, feeder

10-500ton per hour artificial stone and sand production line equipments Covers:

vibrating feeder, jaw crusher, impact crusher, vibrating screen, dust catcher, belt conveyor, ball mill, sand making machine, sand washing machine, rotary dryer zenith production line of cases in various countries (Jeddah;Brunei;Angola;UAE;Palestine;Mexico;Kenya;Ghana;INDIA;KSA; Oman;Egypt;Indonesia; Etc.) zenith all kinds of aggregate plant( Basalt;Granite;Feldspar;River Stone;Limestone;Iron Ore;Dolomite;Calcite;Gypsum;Gold; Bauxite;Copper;Construction Waste;Etc.)

Packaging & Shipping About the logistics 1.Choose the most efficient logistics company; 2. Port in Shanghai, convenient transportation, lead in all directions; 3. Transport packaging is rigorous, accessories in the wooden box; 4. If there is a problem of logistics, can leave a message.

Packaging & Shipping About the logistics 1.Choose the most efficient logistics company; 2. Port in Shanghai, convenient transportation, lead in all directions; 3. Transport packaging is rigorous, accessories in the wooden box; 4. If there is a problem of logistics, can leave a message.  zenith products sales site distribution map

zenith products sales site distribution map  Company Information Shanghai Zenith Mining and Construction Machinery Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices.

Company Information Shanghai Zenith Mining and Construction Machinery Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices.

Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future. We hold "Pursuing the Zenith Technology and Quality" as our management concept all the time.

Relying on absorbing world leading crushing and powder processing technology, advanced management and quality control system, as well as our full efforts, ZENITH has earned high reputation among our customers. Factory picture Headquarter of Zenith is located in Shanghai, China and now we have two manufacturing bases as our strong support.

One is located in Shanghai about 450,000 square meters, and the other is in Qidong city, about 600,000 square meters. It takes about one-hour driving from Shanghai to Qidong city. Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry. With the development of our ZENITH, we would like to help more and more customers start their business in mining and construction industries, offer them the best solution, much more advanced machinery and better service. Our Services We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience. We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Pre-sales Service:

Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Pre-sales Service:The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit zenith working machines or complete plant in the site. To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc. Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also. After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of Zenith, they are now strategically located home and abroad, working for our customers. Large-scale LUM Series Ultrafine Vertical Roller Mill ultra fine grinding mill Technological support:

New products development is a key part of Zenith culture since it was founded. Zenith R&D team is made of 78 senior engineers. The top seven engineers are winners of special central government allowance, which are for the outstanding contribution in science and technology. They are good at not only principle of mechanics, but also integration of theory and practical feedback, based on this they give solid support to our sales. Depending on our national patent machines such as XZM ultrafine mill, MTM mill, B Series Deep Rotor Vertical Shaft Impact Crusher, etc., Zenith win good reputation from markets home and abroad. Recent development includes the MTW series mill, vertical mill, Hydraulic impact crusher,Track mounted crusher, PEW series jaw crusher, etc. Deeply believe that the measure of our worth is in the development and innovation of new products, and we are pursuing the “Zenith direction of technology and quality” all the way. FAQ

We have more than 100 kinds of products, there is always a right for you! If you are new for this business: Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry. 1.What is the type and size of raw material? 2.What is your required capacity(t/h)? 3.what is the raw material input size? 4.what is the output size of your product? Look forward to your inquiries! ....

We have more than 100 kinds of products, there is always a right for you! If you are new for this business: Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry. 1.What is the type and size of raw material? 2.What is your required capacity(t/h)? 3.what is the raw material input size? 4.what is the output size of your product? Look forward to your inquiries! .... Send your inquiry to this supplier

Send Inquiry