1 / 6

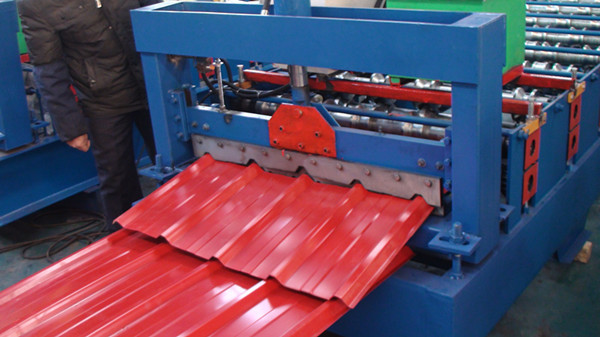

KEXINDA 840 sheet rollforming machine

| Model No. : | curve roof roll forming machine |

|---|---|

| Brand Name : | kexinda curve roof roll forming machine |

Product description

1 | Decoiler(manual or hydraulic for options) | 1 set |

2 | Feeding device | 1 set |

3 | Main Forming Machine | 1 set |

4 | Hydraulic step press device | without |

5 | Hydraulic cutting device | 1 set |

6 | Hydraulic Station | 1 set |

7 | PLC computer control system | 1 set |

8 | 4m Run Out Table | 1 set |

1 | Inner diameter of manual decoiler | 500mm |

2 | Outer diameter of manual decoiler | 1200mm |

3 | Weight capacity of manual decoiler | 5T |

4 | Appearance Size | 6500mm*1300mm*1200mm |

5 | Raw Material | colored steel or galvanized steel |

6 | Roller material | high grade 45# forged steel,polished,heated,quenched |

7 | Blade Material | CR12 with polished |

8 | Chrome Coating | coated with 0.05mm hard chrome |

9 | Control System | PLC control |

10 | Main motor power | 4KW |

11 | Hydraulic Power | 4KW |

12 | Roller station | 13 rollers |

13 | Material of chain | high grade 45# steel:polished,heated,quenched HRC 45-50 |

14 | Speed of Product | 10-12m/min |

15 | Thickness range | 0.2-0.7mm |

16 | Type of cutting | hydraulic cutting |

17 | Coil Width | 1000mm |

18 | Cover Width | 840 mm |

19 | Material of rack | complete welded structure of A3 steel plate |

20 | Machine frame stand | welded with 300H-steel |

21 | Type of forming machine | single station with chain transmission |

22 | Thickness of frame | 14mm |

23 | Shaft Diameter | 75mm |

24 | Weight | about 3.5T |

25 | Voltage | 380V 50HZ 3Phases( or as your local requirement) |

26 | Electrical control | PLC frequency control system |

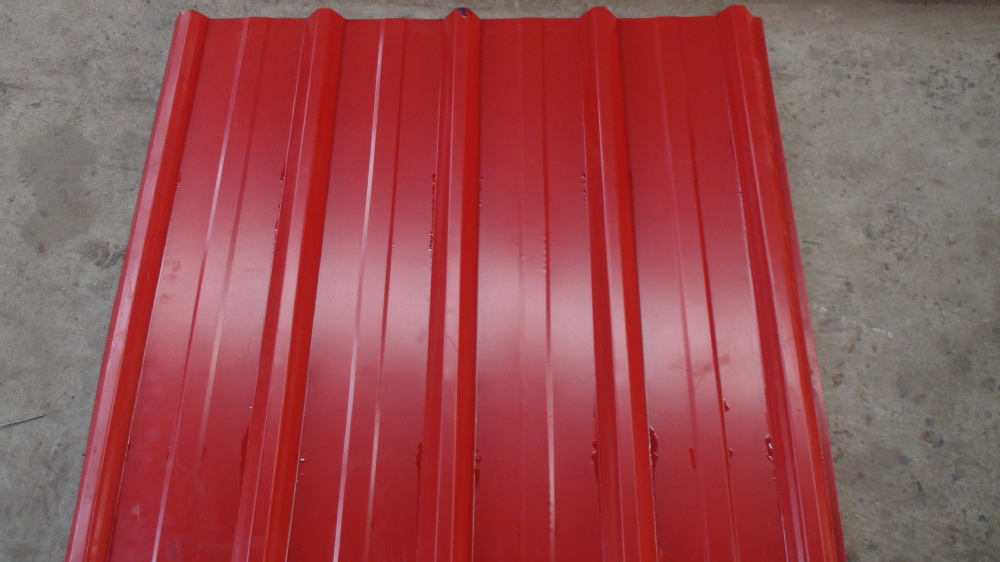

KEXINDA 840 roof panel wall panel rollformer machine pictures

KEXINDA 840 roof panel wall panel rollformer machine pictures  KEXINDA 840 roof panel wall panel rollformer machine

KEXINDA 840 roof panel wall panel rollformer machine

Cold Roll Forming Machine steel floor forming machine

Cold Roll Forming Machine steel floor forming machine this products used in tour beauty spot,hotel,exhibition,holiday village building Cold Roll Forming Machine Parameter:

1.Suitable to process:Colored Steel plate, galvanized board

2.Width of the plate:1000mm

3.Rollers:12-13rows

4.Rolling material: Forging Steel 45#

5.Rolling galvanization thickness:0.05 mm

6.Material of the cutting blade :Cr12

7.Hydraulic oil :40#

8.Dimensions:6.7*1.35*1.51m

9.Power:3+3kw

10.Thickness of the plate:0.3-0.6mm

11.Productivity:8-10m/min

12.Diameter of the roller:70mm

13.Weight:About 3.8 T

14.Voltage:380V 50Hz

15.Processing precision : within 1.00mm

16.Equipment components: Man-made uncoiler, Roll forming machine, compture control system, hydraulic control system, cutting

17.Transportation:one complate equipment need one 40feet container to hold

18.Delivery Time:30%deposit,and balance before delivery

19.Standard components: Chain 1 pcs, Hydraulic oil pipes: 2 pcs, electromagnetism valves 1 pcs. limit switch:2 pcs

20.This machine is compose of feeding table,forming machine,forming cutting device, hydraulic system,computer control system,discharge table.

Optional devices have manual uncoiler,hydraulic uncoiler,aoto stacker and so on.(Optional)

21.Our products are widely used in various industral factory,civilian building, warehouse and easy steel building manufacturing,and have features such as nice apparance and durable. Packaging & Shipping

Our Services Guarantee : 24 months guarantee for the machine. Service: We send technician to your country to fix the machine. All life door to door service The buyer should bear all the cost including: visa , Roundtrip tickets and suitable accommodation, also buyer should pay salary Company Information Botou Kexinda Roll Forming Machinery Co., Ltd. is a leading manufacturer of roll forming machine in China since 1998. We has many years' experience in designing and producing various of roll forming machines. We own a high-quality and professional team in designing, scientific researching, producing, sales and after-sales services. It has a strong technical force and many professional technicians in this field. We have advanced production equipments, strong production capacity and perfect after-sales services system. Our products have passed European CE certificate. And we carry out the standards strictly in the course of production. We are the specialized manufacturer in producing sandwich panel line all kinds of roll forming machines, such as glazed tile roll forming machine, roof/wall panel roll forming machine, double layer roll forming machine, C & Z purlin machine, floor deck roll forming machine, highway guardrail machine, dust shield machine, ridge cap machine, roll shutter door machine, uncoiling & leveling & slitting & recoiling line, all kinds of decoilers and stackers, and many other related equipments like shear, punch, slitter, leveler, crimping curving, bending and so on. We provide our customers with excellent products and integrated services, our products and brand have been approved unanimous by all customers and enjoyed good reputation from customers of domestic and overseas. Our products not only extended all over domestic markets but also entered international markets. At present, our products have been exported to many countries and regions, Russia, Saudi Arabia, the USA, Spain, Australia, Ethiopia, Kenya, Ghana, Srilanka, Malaysia, Nigeria, Afghanistan, Kazakhstan, Iran, India, Brazil, Mexico, Bolivia, Uruguay and so on. Insisting on correct principle, rooted in precise philosophy, and working to extend our presence internationally, we are looking forward to cooperating with your company for mutual benefit in the near future. FAQ 1 How can i get to your factory? First, fly to Beijing or Shanghai, Beijing is near our city, about 1 hours by highway train. Second, when arrive our city Cangzhou, Cherish and the team can pick you up, it is about 5 minutes from the sation to our office, It is about 40 minutes from the sation to our factory Kexinda.

Our Services Guarantee : 24 months guarantee for the machine. Service: We send technician to your country to fix the machine. All life door to door service The buyer should bear all the cost including: visa , Roundtrip tickets and suitable accommodation, also buyer should pay salary Company Information Botou Kexinda Roll Forming Machinery Co., Ltd. is a leading manufacturer of roll forming machine in China since 1998. We has many years' experience in designing and producing various of roll forming machines. We own a high-quality and professional team in designing, scientific researching, producing, sales and after-sales services. It has a strong technical force and many professional technicians in this field. We have advanced production equipments, strong production capacity and perfect after-sales services system. Our products have passed European CE certificate. And we carry out the standards strictly in the course of production. We are the specialized manufacturer in producing sandwich panel line all kinds of roll forming machines, such as glazed tile roll forming machine, roof/wall panel roll forming machine, double layer roll forming machine, C & Z purlin machine, floor deck roll forming machine, highway guardrail machine, dust shield machine, ridge cap machine, roll shutter door machine, uncoiling & leveling & slitting & recoiling line, all kinds of decoilers and stackers, and many other related equipments like shear, punch, slitter, leveler, crimping curving, bending and so on. We provide our customers with excellent products and integrated services, our products and brand have been approved unanimous by all customers and enjoyed good reputation from customers of domestic and overseas. Our products not only extended all over domestic markets but also entered international markets. At present, our products have been exported to many countries and regions, Russia, Saudi Arabia, the USA, Spain, Australia, Ethiopia, Kenya, Ghana, Srilanka, Malaysia, Nigeria, Afghanistan, Kazakhstan, Iran, India, Brazil, Mexico, Bolivia, Uruguay and so on. Insisting on correct principle, rooted in precise philosophy, and working to extend our presence internationally, we are looking forward to cooperating with your company for mutual benefit in the near future. FAQ 1 How can i get to your factory? First, fly to Beijing or Shanghai, Beijing is near our city, about 1 hours by highway train. Second, when arrive our city Cangzhou, Cherish and the team can pick you up, it is about 5 minutes from the sation to our office, It is about 40 minutes from the sation to our factory Kexinda. 2 Do you have some online tools? Yes, my whatsapp is: + 86 17703278193 Skype:rollformingmachine6 TM: cn1000393166

Send your inquiry to this supplier