1 / 5

K72 series 4jaws Independent lathe chuck

| Model No. : | K72 250 |

|---|---|

| Brand Name : | HERF |

| Number Of Jaws : | 4 Jaws |

Zhongwei, Ningxia, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- SGS Certification

Product description

I. Summary

K72 250 is K72 series Four jaw Independent lathe chuck. 4-jaw independent chucks. Chuck adopt short cylindrical center mounting. Chucks adopt threaded transmission structure to move jaws independently by threaded bars to clamp workpieces .The steel chucks have high speed, high clamping force , long using life stc.

II. Model instruction

1. Model K72 250 : Size 250mm(10inch)

2. indepnedent and adjustable ,suitable for machining all kind of special-shaped workpieces

3.Chucks matched with two-pieces jaw

III.Chuck Selection

1. Users should choose a suitable chuck to the demanded dimensions of workpieces and permissible clamping range of chuck

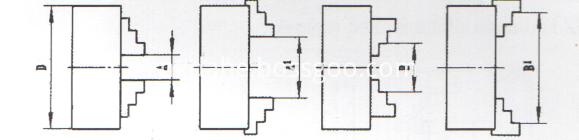

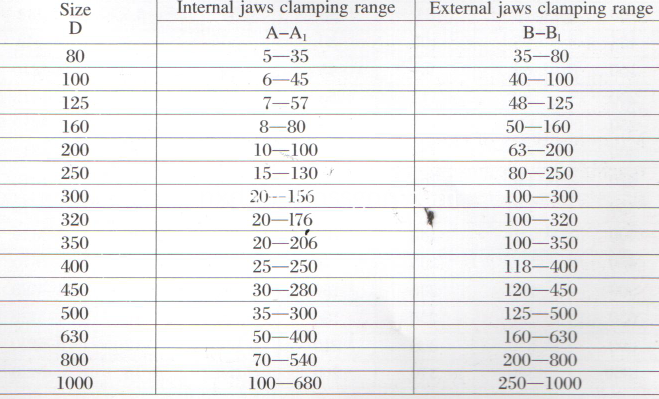

FIG 1.

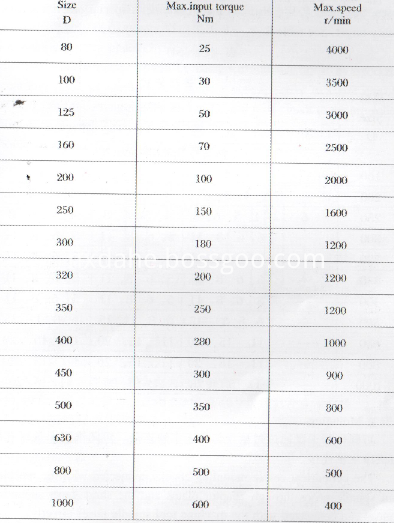

TABLE 1.

2.When chose a chuck you should consider the main parameters of machine tool such as its max. speed etc .

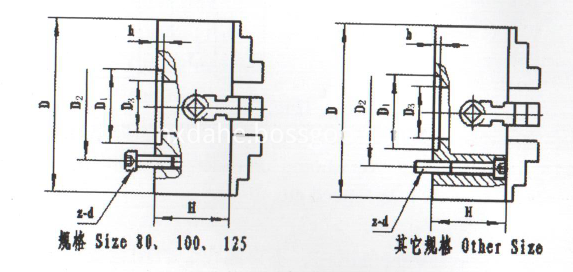

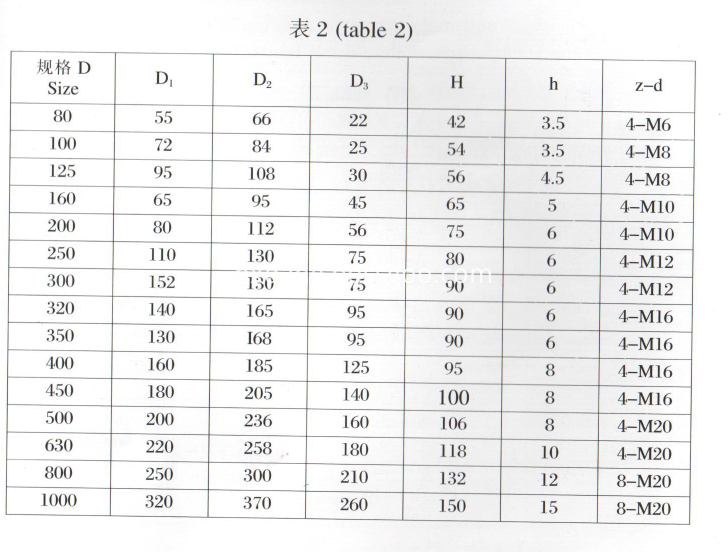

IV. The basic parameters of cylindrical cnetre mount chucks ,See FIG. 2, TABLE. 2 AND MAIN FEATURE ,SEE TABLE 3.

FIG. 2

TABLE.2

TABLE. 3

V. Mounting a cylindrical centre chuck

VI. Operation.

1.Check and test items as below before operation

(1)Ensure the chuck mounting be tight.

(2)Insert the wrench into the threaded bar hole and turn it to make the Jaw move freely.

(3)Setting lowest spindle rotated speed if it runs normally then increase speed and check its run-out and other abnormal phenomenas

2. Operation of the chucks

(1)Make the workpiece to conform with the clamping arc in the

(2)Use the attached wrench to clamp workpiece( clamping individually with 4 jaws) and the input torque should not exceed the values of table 3

3.Caution

a)Do not add the tube on the wrench when clamp workpiece to avoid the input torque to exceed its limit and break chuck

b)Do not clamp workpiece in the max clamping range if possible

c) Do not run at max speed when approach the max clamping limit

d) Do not exceed chucks max speed during operation

VII. Maintenance

1. Chucks should be maintained while the machine tools maintain

2. Lubricate and clean (use the compressed air) the chucks every day in order to maintain its accuracy and durability

3. Wash and lubricate all the working surface of the chucks at least two times every year. When the using frequency of the machine tool grow or at the special operation conditions, add the maintenance times of the chucks

Zhongwei, Ningxia, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- SGS Certification

Send your inquiry to this supplier