1 / 4

Intelligent electromagnetic flow meter for sewage or dirty water

| Model No. : | LD |

|---|---|

| Brand Name : | DDTOP |

Product description

1. Sensor parameter 1.1Flange connection (LD1)

1. Sensor parameter 1.1Flange connection (LD1) Suitable diameter | DN15-DN1000, other diameters are non-standard, according to user request |

Measuring pipe lining material | F46 (FEP Teflon), P0 (polyolefin), PUR (polyurethane) |

The electrode material | 316L, Hc(Hastelloy C),Hb(Hastelloy B),Ta() |

Operating pressure | DN15-DN80 diameter: 4.0Mpa (standard) DN100-DN150 diameter: 1.6 Mpa(standard) DN200-DN1000 diameter: 1.0Mpa (standard) |

More than the pressure standard is non-standard type, according to user requirement order other flange standard | |

Fluid temperature | F46lining:-40°C-180°C,P0lining: -20°C-80°C;PUR lining: 0-50°C |

Technology of connecting flange | Flange standard of this book is HG/T20592-2009,or according to user requirement order other flange standard. |

Grounding ring material | 304,321,316,Hc,Ti,Cu |

Measure range | flow rate 0.1-10m/s,each diameter flow= Tube cross-sectional area×flow rate |

Accurcy class | 0.3,0.5(flow rate≥0.5m/s),1.0(flow rate<0.5m/s),2.0(flow rate<0.2m/s) |

Electrical conductivity | >5µs/cm |

Output signal | 4-20mA,load≤750Ω;0-100Hz output pulse, with power24V, >10mA;RS485;4-20mA+HART |

Supply power | 220VAC±10%,50Hz±1Hz;24VDC±10% |

Power consumption | <7W |

Explosion proof | Exd(ia)iaqⅡCT6,Exd(ia)iaqⅡBT4 |

Housing protection | integrated: IP65; Split type: sensor IP68,converterIP65 |

Ambient temperature | -25°C to 60°C(Explosion proof to50°C) |

Ambient humidity | ≤85%RH(20°C) |

Electrical interface size | M20×1.5,1/2NPT(outside diameter of cableφ6-φ10) |

Diameter (DN) | The minimum flow measuring range (m/s)0-0.5m/s | The maximum flow measuring range (m/s)0-10m/s |

15 | 0-0.3 m³/h | 0-6.4 m³/h |

25 | 0-0.9 m³/h | 0-17.7 m³/h |

32 | 0-1.5 m³/h | 0-28.9 m³/h |

40 | 0-2.3 m³/h | 0-45.2 m³/h |

50 | 0-3.5 m³/h | 0-70.2 m³/h |

65 | 0-6.0 m³/h | 0-119.4 m³/h |

80 | 0-9 m³/h | 0-180 m³/h |

100 | 0-14 m³/h | 0-282.6 m³/h |

125 | 0-22 m³/h | 0-441.6 m³/h |

150 | 0-31.8 m³/h | 0-636 m³/h |

200 | 0-56.5 m³/h | 0-1130 m³/h |

250 | 0-88.3 m³/h | 0-1766 m³/h |

300 | 0-127.2 m³/h | 0-2543 m³/h |

350 | 0-173.1 m³/h | 0-3462 m³/h |

400 | 0-226.1 m³/h | 0-4522 m³/h |

500 | 0-353.3 m³/h | 0-7065 m³/h |

600 | 0-508.7 m³/h | 0-10174 m³/h |

700 | 0-692 m³/h | 0-13847 m³/h |

800 | 0-904 m³/h | 0-18086 m³/h |

900 | 0-1145 m³/h | 0-22890 m³/h |

1000 | 0-1413 m³/h | 0-28260 m³/h |

1200 | 0-2035 m³/h | 0-40694 m³/h |

1400 | 0-2770 m³/h | 0-55390 m³/h |

1600 | 0-3617 m³/h | 0-72346 m³/h |

1800 | 0-4578 m³/h | 0-91562 m³/h |

2000 | 0-5652 m³/h | 0-113040 m³/h |

4. Material of liner selection

4. Material of liner selection Material | Character | Range of application |

F-46 fluorinated ethylene-propylene | 1. Chemical stability, resistance to almost all chemical media corrosion. 2. heat-resistant, long-term work at 180 ℃. 3. High mechanical strength, good wear resistance. 4. The inner surface is smooth, and is not easy to adhere to precipitate. 5. The inner lining with metal mesh, vacuum-resistant, anti-vacuum. | All fluid addition to strong wear medium such as mortar. It can be used to medium has sanitary requirement such as drinks. |

PO polyolefin | 1. Has good physical and chemical properties, is a more advanced anti-corrosion materials now. 2. Long-term using at 80 ℃. 3. Has good stress cracking resistance, better than rubber. 4. Has good impact resistance. 5. Has good rigidity. | All fluid in addition to gasoline, diesel and acetaldehyde, the temperature is not higher than 80 ℃. |

PUR polyurethane | Good wear resistance, isn’t resistant to corrosion, operating temperature can not exceed 50 ℃ | Mortar and other strong abrasive fluids |

Material | Corrosion resistance |

|

Hc hastelloy C |

Anti-oxidizing acids such as nitric acid, chromic acid and sulfuric acid mixture. Also resistant to oxidizing salts or other oxidant-containing corrosive environment. Seawater, alkali solution, chloride solution with good corrosion resistance.

|

|

Hb hastelloy B |

Sulfuric acid, phosphoric acid, hydrofluoric acid and other non-oxidizing acid, alkali, salt, with good corrosion resistance.

|

|

Ta tantalum |

Addition to hydrofluoric acid, it can resist almost all chemical media. Because of its price is so high, it is only used for hydrochloric acid and concentrated sulfuric acid.

|

|

316L stainless steel |

It is used for weak corrosive medium such as industrial water, domestic water and waste water, neutral solution and weak acid such as carbonic acid and acetic acid.

|

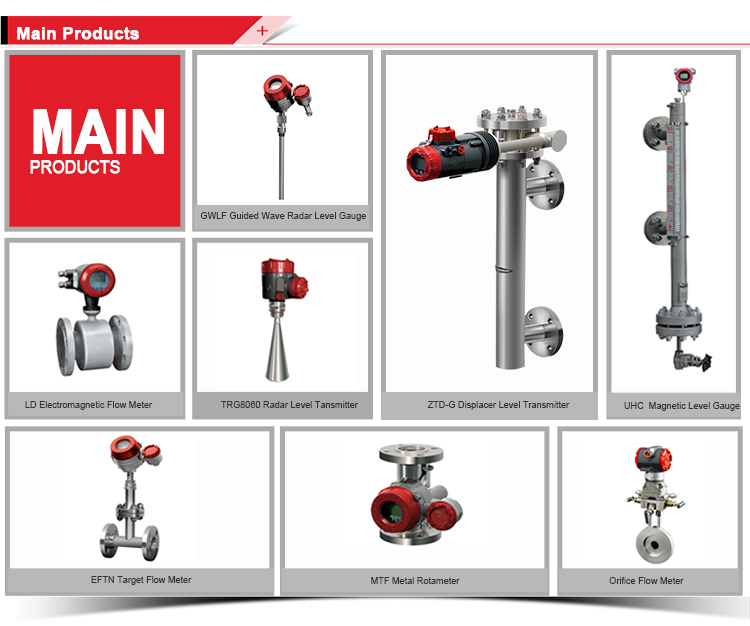

6. Ground ring selection 6.1 Standard ground ring: both sides of sensor must install ground ring on plastic and cathodic protection pipes. 6.2 protection ring with neck: if medium has strong abrasiveness, you should select protection ring with neck to protect liner. 6.3 protection ring: F46 liner sensor should select protection ground ring, fixed on flange via screw to protect the flanging of liner from damage. The material of ground ring is stainless steel 1Cr18Ni9Ni, if you have special requirement, please tell us when ordering goods. 7. Protection class selection of house Protection class of the housing on integrated flow meter is IP65, the sensor section is IP68, and transmitter section is IP65. 8. The determination of the fission You should use split type flow meter in hostile environment such as ponding, corrosion, high temperature, low temperature, strong vibration and maintenance inconveniently, etc. Transmitter is connected to sensor only with a cable. Please ensure the specific length with the manufacturer when ordering goods, if not, the length is only 5 meters. Others select integrated flow meter. When you can’t make the decision, you can ask to manufacturer. You May Like:

6. Ground ring selection 6.1 Standard ground ring: both sides of sensor must install ground ring on plastic and cathodic protection pipes. 6.2 protection ring with neck: if medium has strong abrasiveness, you should select protection ring with neck to protect liner. 6.3 protection ring: F46 liner sensor should select protection ground ring, fixed on flange via screw to protect the flanging of liner from damage. The material of ground ring is stainless steel 1Cr18Ni9Ni, if you have special requirement, please tell us when ordering goods. 7. Protection class selection of house Protection class of the housing on integrated flow meter is IP65, the sensor section is IP68, and transmitter section is IP65. 8. The determination of the fission You should use split type flow meter in hostile environment such as ponding, corrosion, high temperature, low temperature, strong vibration and maintenance inconveniently, etc. Transmitter is connected to sensor only with a cable. Please ensure the specific length with the manufacturer when ordering goods, if not, the length is only 5 meters. Others select integrated flow meter. When you can’t make the decision, you can ask to manufacturer. You May Like:

Free OEM and free LOGO service accepted! To PROTECT our customers, all prices on the Net are just a guiding price. Leave an INQUIRY to know more details about PRICE, PACKING, SHIPPING and DISCOUNT.

Free OEM and free LOGO service accepted! To PROTECT our customers, all prices on the Net are just a guiding price. Leave an INQUIRY to know more details about PRICE, PACKING, SHIPPING and DISCOUNT.  Company Information

Company Information

Our Services

Our Services  Packaging & Shipping

Packaging & Shipping  Trade Shows

Trade Shows

Send your inquiry to this supplier