Video

1 / 6

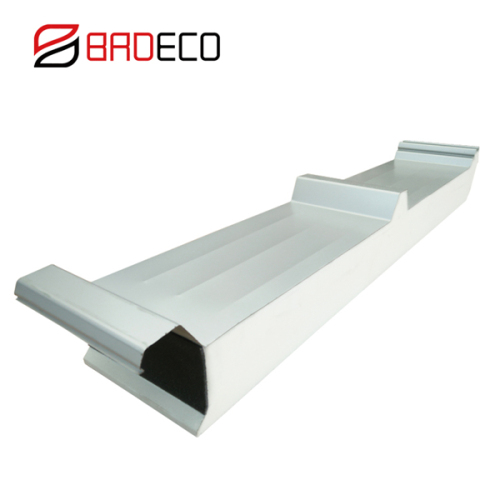

insulated pu sandwich panel insulation pu foam roof sandwich panel

$17.00

≥300 Square Meter

Options:

- PIR Sandwich Panels

- Polyurethane Sandwich Panels

- PU sandwich roof panel

Send Inquiry

| Warranty : | More Than 5 Years |

|---|

More

BRD New Material Co., Ltd.

You might also like

Product description

Product Description

As a new building material in construction, the polyurethane roof panel has been the most suitable choice for projects. The polyurethane roof panel is divided into two types: The three waves of polyurethane composite roof panel, The four waves of polyurethane composite roof panel. The characters of PU roof panel are heat insulation, waterproof, soundproof, and easy to install. The excellent features are the reason why so many people choose it as roof board.

Specification

Type | Polyurethane Sandwich Roof Panel |

Core Material | Polyurethane |

Surface Material | Color Steel Sheet |

Core Thickness | 100mm |

Steel Thickness | 0.4mm |

Length | 11.8m |

Fire Rating | B |

Density | 40-45kg/m³ |

Water Absorption(kg/m³) | <0.30 |

Color | Any Ral Color |

Surface Appearance | Small wave, Flat, Embossment, Big rib, etc. |

Advantages | Fireproof/Insulation/Waterproof/Easy Install/Lightweight |

Usage | prefab houses, warehouse, factory, shop, office ,etc. |

Price Description | double 0.4mm steel sheet, 100mm core material |

Details Images

Large carrying capacity

Large panel design, reinforced surface size, increase span space, slab design adopts trapezoidal high wave crest, roof panel has

large bearing capacity and fast drainage.

large bearing capacity and fast drainage.

Airtight and soundproof

Polyurethane has good sound-absorbing properties and can reduce the sound caused by impacts such as rain and hail.

Waterproof and rustproof

The unique interlocking joint design between the polyurethane wall panels effectively prevents water vapor intrusion. Screw hidden

node design prevents rust and has a long service life.

node design prevents rust and has a long service life.

Strong and sturdy

The polyurethane roof panel is filled with rigid foamed polyurethane, which has high strength and rigidity. Polyurethane panels

are produced in a highly controlled, constant temperature environment in the factory, with stable quality, fast construction, and

a service life of more than 35 years.

are produced in a highly controlled, constant temperature environment in the factory, with stable quality, fast construction, and

a service life of more than 35 years.

Advantage

1. Exclusively adopt the 3 wave roof, embedded installation, dark nail waterproof technology, easy installation.

2.Adopt the 40 cm peaks, increase the surface strength, easy drainage, reducing both snow load and wind load by 170%.

3.Super flame retardation

The coefficient of thermal conductivity is 0.023w/(m•k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building heat and brings enormous economic benefits.

4. Easy and quick installation

Compared with traditional thermal insulation methods, BRD use less material while the installation process are more time-saving and labor-saving leading to lower building costs.

Cases Display

Polyurethane sandwich panels are widely used in large industrial plants, cold storage, garages, mobile houses, exhibition halls, exhibition halls, stadiums, shopping, airports, power plants, villas, hospitals, stratum and high-rise buildings and other fields. Due to excellent thermal insulation performance, the main Applied to roofs and walls of industrial and civil buildings.

Company Profile

BRD GROUP

BRD Group, was established in 1995, we have more than 500 existing staffs in the company, and have more than 30 million square meters production area. BRD Group is a modern enterprise which focusing on full systems of steel building, such as steel structure, pu sandwich panel, thermal insulation and decorative panel, steel truss deck, and light steel villa.

BRD also has a strong productivity. We introduced several Italian totally automatic production lines and adopted Chinese Total Productive Management System. The annual output includes 1.2 million meters of polyurethane sandwich panel, and 10 million tons of steel structure. We take part in many famous exhibitions, like Canton Fair, Thailand ASEAN International Exhibition, and so on. We sincerely hope to cooperate with you to create a double win situation.

In the past 26 years, BRD committed is to creating high-quality products, internal, external finishes of solutions, to provide customers with high quality, safe, environmentally friendly building materials solutions, to meet all your needs from product design, technology, sales and construction.

BRD Exhibition

Our Customers

Till now, BRD sandwich panels have been exported to over 50countries and places and more and more customers have made twice or third order, which proves BRD is worth of your reliance.

Certificate

Contact Us

FAQ

Q: Are you a manufacturer or a trading company?

A: BRD New Materials Co., Ltd was established in 1995, located in south of Weiwu Road, Chang'ge Industrial Zone, Chang'ge, Henan. We are the lead in production and sales domestically, with 18 years' concentration on industry.

Q: What is required for a detailed quotation?

A: Please let us know the material, size, color, quantity, application, etc.

Q:How about the Technical Support?

A:We will provide installation instruction and video for you, technicians will be sent to help you if it is necessary. However, the visa fee, air tickets, accommodation,wages will be provided by buyers.

Q: How long is your delivery time?

A:Our monthly production includes 120,000 square meters of plate and 10,000 tons of all kinds of steel, with 3,000 of raw materials in stock, to guarantee100% on time delivery.

Q: How do you guarantee the quality of the products?

A:Each product from our factory has strict testing procedures, and must be 100% quality before delivery. Believing, Respecting, Doing the best.

Q: How can I get the quotation of the project ?

A:We will quote according to your drawings if you have.Our engineer will design drawings for you to confirm if you don't have, and then offer you a quotation.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Video

Send your inquiry to this supplier

Send Inquiry