1 / 5

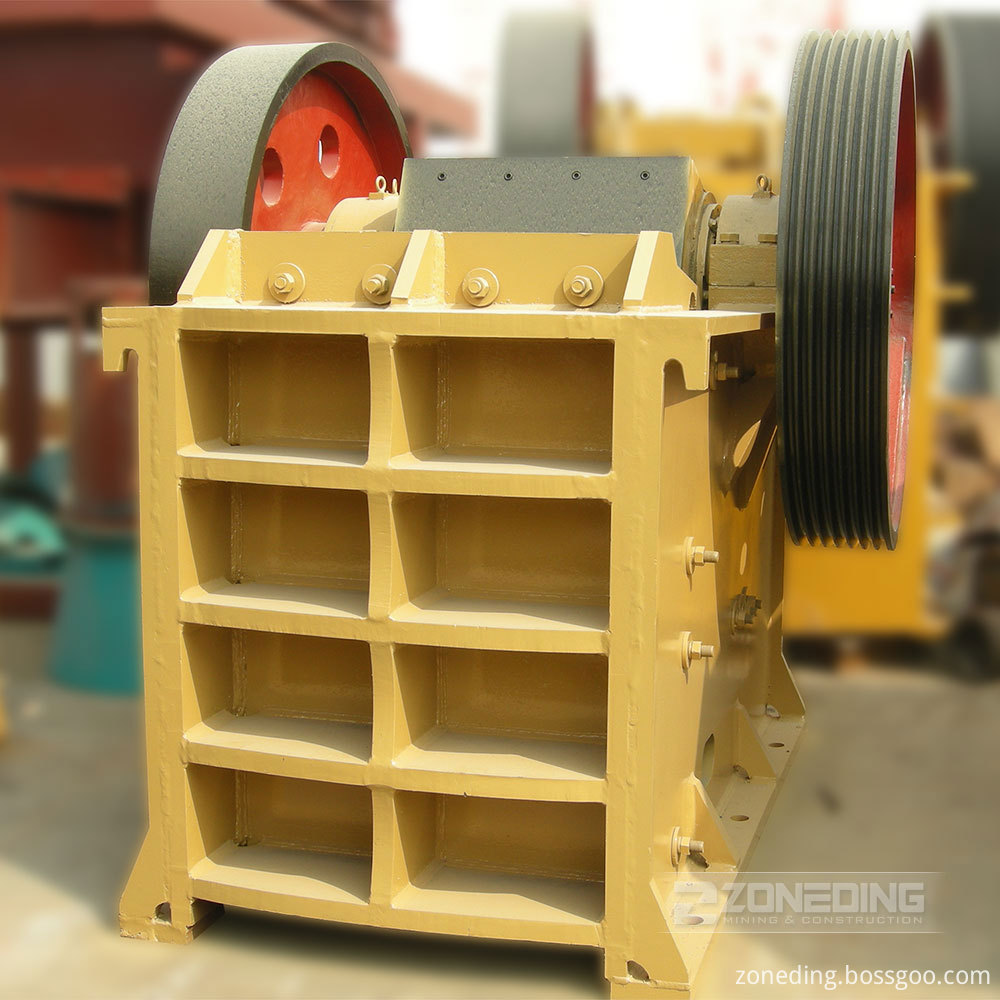

Industrial types of second hand jaw crusher pdf

Get Latest Price

Send Inquiry

| Model No. : | PE-400*600 |

|---|---|

| Brand Name : | Zoneding |

| Type : | Jaw Crusher |

More

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co.,Ltd.

You might also like

Product description

Large Crushing and Low Energy Jaw Crusher

Product Introduction of Jaw Crusher:

Jaw Crusher Machine PE series is ideally suitable for primary and secondary crushing. Primary Jaw Crusher is widely used in mining, metallurgy, construction, highway, railway, irrigation and chemical industries, and our Stone Crusher Machine have the features of high reduction ratio, even powder sizes, low power consumption and easy maintenance.Mini Jaw Crusher is up to 320 Mpa. SDLY Stone Crusher Machine is easy to be installed, operated and maintained.

Main Features of Jaw Crusher:1. Simple structure, easy maintenance;1. The movable jaw assembly uses high quality casting steel;

2. The heavy eccentric shaft adopts forging, heat treatment, annealing, crack detection etc. processing,then it can guarantee the stability of lead plane.

3. The inner bearing uses aligning roller, double row double roller bearing which can guarantee it with higher carrying capacity.

4. Simple structure, easy operation, convenient maintenance.

5. Deep crushing cavity and without dead zone, improve the ability of feed and output.

6. Large adjustable range of discharge opening can meet the different requirements of different specifications.

The strip and strip pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the movable jaw runs down, then the materials are crushed into pieces. It will become bigger when the movable jaw runs up. The movable jaw board leaves the fixed jaw board under the action of pole and spring ,then the end products come out from the crushing cavity.

Stone Crusher Machine Features And Benefits:

1. The movable jaw assembly uses high quality casting steel;1. Simple structure, easy maintenance;

2. High crushing ratio, even output granularity;

3. High reliability, low investment;

4. Low noise, less dust.

5. Jaw Crusher have flexible capacity.

Product Pictures Show:

Send your inquiry to this supplier

Send Inquiry