1 / 1

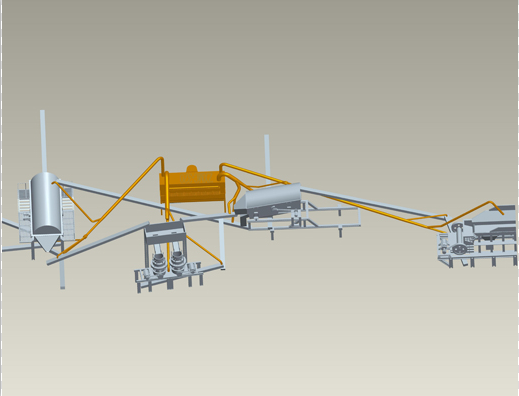

Industrial Filter Bag Dust Collector System for Crushing

| Model No. : | ZXMC-100-2.5 |

|---|---|

| Brand Name : | ZXMC |

| Medium Material : | Chemical Synthetic Fiber |

Product description

The working principle of pulse dust collector: After getting into sedimentation chamber, thick dust fall because of sudden decreasing speed, and fine one is raised by the air flow. Clean air passes through filter bags, gets into venturi pipes and expelled from the clean air chamber.

Dust accumulates on surface of filter bags and forms dust layer, which is to increase resistance for the sake of improving dedusting efficiency. To keep the working condition steady, the resistance of dust collector must be limited in an area (generally 1200-1500Pa), so dust layer should be cleaned regularly. Pulse dust collector adopts the compressed air as the clean power. Each row of filter bag is equipped with a1"jet pipe which forms a pulse net. According to the definite program, the controller urges the pulse valve to spray. At that time, compressed air through6.4mmnozzles on blow pipes, and induce ambient air, which is several times stronger than primary air, goes into filter bags through venturi pipe. In a instantaneous time, filter bags inflate rapidly and shakes off the dust layer. Meanwhile, the air current reversed and some dust in the filter bag is blown out.

The construction of the spray system, a side of the pulse valve connects with compressed air package and B side connects with the gas ejector pipe. The backpressure chamber of pulse valve connects with the control valve. The work of control valve is completed by the controller. If there is no signal with controller, the moving core of the controller block the air vent, the pulse valve is closed. If there is signal, the control valve will prompt the backpressure chamber of pulse valve to connect with the atmospheric pressure (releasing pressure) and the pulse valve is turned on. The compressed air in the air bag goes into the Venturi pipe through pulse valve and the small hole of spray and blow pipe, which makes the filter bag full of positive pressure instantaneously and so that the dust cleaning is finished.

Send your inquiry to this supplier