1 / 1

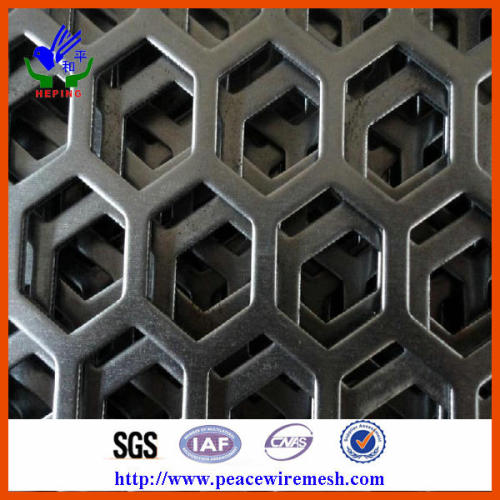

Hot Sale Perforated Metal Mesh (HP-C5)

Get Latest Price

Send Inquiry

| Model No. : | HP-C5 |

|---|

Peaceful Hardware & Mesh Co., Ltd.

You might also like

Product description

Concept definition

Definition: Metal mesh is the marked holes in different materials with different shapes to suit different needs.

Material: Metal mesh with most raw materials are: Stainless steel, carbon steel, galvanized sheet, PVC sheet, cold rolled coils, hot rolled steel, aluminum copper and so on.

Category: Pattern mesh, forming mesh, heavy metal mesh, perforated metal mesh special thin, porous metal mesh, perforated metal mesh wire cutting, laser punching net.

2 Hole Specifications

Perforated metal mesh main specifications are rectangular hole, square hole, diamond hole, hole, a long hole, hexagonal hole, cross hole, triangle hole, long waist hole, plum blossom hole, scale hole, hole pattern, character mesh, herringbone holes, pentagram hole, irregular holes, from the dark hole, hole, holes and other blinds.

1 coil thickness 0.2mm-1mm, length 20m

2 aperture 3mm-10mm

3 Zhang thickness 0.2mm-20mm; Width * length ≤ 1.5m * 5m

4 aperture 0.25mm-200mm

Perforated metal mesh ( 10 )

3 punching way

A continuous punching in the same direction: The use of partially overlapping rectangular metal mesh mold processing, it can be processed long hole, cutting and so on.

2, continuous forming: Forming a large die size than the metal mesh forming methods, such as large-size blinds, roll bars, rolling stairs and other processing methods.

3, nibble: Use small round mold with a smaller step for continuous punching arc processing methods.

4, continuous punching multi-directional: The use of small metal mesh mold macroporous processing methods.

4 defect correction

( 1 ) generated when the punching eccentricity correction: Because when punching anvil surface uneven, crooked and punch both ends of the billet heating surface uneven, eccentric aperture will produce. Correction methods available immersion method: When operating the thin side of the hole wall immersed in water, its temperature decreases, then punch reaming, the wall thickness of the side due to the higher temperature, plastic and thin, so that the whole wall forgings thick uniform, eccentric [ 1 ] is corrected. This method is suitable for plastic good material.

( 2 ) when punching blanks aliasing. I. E., below the metal punch pushed to around the height of the blank is reduced, the diameter increases, the recessed end surface, the end surface of the projection. The size and extent of aliasing before punching blank diameter D0, height H0 and pore size d1 and other relevant, D0/d1 smaller, the more severe the degree of aliasing. Correction approach is: Should control D0/d1 ≥ 2.5 ~ 3 as well. If you are punching a larger diameter, such as D0/dl <2.5, generally the first punch holes, then reaming to obtain pore size requirements.

5 practical purposes

Perforated metal mesh can be used for lots across the city highway, railway, subway and other transportation facilities in the municipal environmental noise control barriers, architectural objects, walls, generator room, factory buildings, and other noise sources of acoustic noise with sound absorbing panels, can be used for the ceiling of the building, wall suction audio network, audio speaker mesh material that can be used for building stairs, balconies, green chairs beautifully decorated plate can be used for machinery and equipment, protective cover, ornate speaker grille, food, feed, grinding sieve used in mining, mining sieve, sieve the word,

Definition: Metal mesh is the marked holes in different materials with different shapes to suit different needs.

Material: Metal mesh with most raw materials are: Stainless steel, carbon steel, galvanized sheet, PVC sheet, cold rolled coils, hot rolled steel, aluminum copper and so on.

Category: Pattern mesh, forming mesh, heavy metal mesh, perforated metal mesh special thin, porous metal mesh, perforated metal mesh wire cutting, laser punching net.

2 Hole Specifications

Perforated metal mesh main specifications are rectangular hole, square hole, diamond hole, hole, a long hole, hexagonal hole, cross hole, triangle hole, long waist hole, plum blossom hole, scale hole, hole pattern, character mesh, herringbone holes, pentagram hole, irregular holes, from the dark hole, hole, holes and other blinds.

1 coil thickness 0.2mm-1mm, length 20m

2 aperture 3mm-10mm

3 Zhang thickness 0.2mm-20mm; Width * length ≤ 1.5m * 5m

4 aperture 0.25mm-200mm

Perforated metal mesh ( 10 )

3 punching way

A continuous punching in the same direction: The use of partially overlapping rectangular metal mesh mold processing, it can be processed long hole, cutting and so on.

2, continuous forming: Forming a large die size than the metal mesh forming methods, such as large-size blinds, roll bars, rolling stairs and other processing methods.

3, nibble: Use small round mold with a smaller step for continuous punching arc processing methods.

4, continuous punching multi-directional: The use of small metal mesh mold macroporous processing methods.

4 defect correction

( 1 ) generated when the punching eccentricity correction: Because when punching anvil surface uneven, crooked and punch both ends of the billet heating surface uneven, eccentric aperture will produce. Correction methods available immersion method: When operating the thin side of the hole wall immersed in water, its temperature decreases, then punch reaming, the wall thickness of the side due to the higher temperature, plastic and thin, so that the whole wall forgings thick uniform, eccentric [ 1 ] is corrected. This method is suitable for plastic good material.

( 2 ) when punching blanks aliasing. I. E., below the metal punch pushed to around the height of the blank is reduced, the diameter increases, the recessed end surface, the end surface of the projection. The size and extent of aliasing before punching blank diameter D0, height H0 and pore size d1 and other relevant, D0/d1 smaller, the more severe the degree of aliasing. Correction approach is: Should control D0/d1 ≥ 2.5 ~ 3 as well. If you are punching a larger diameter, such as D0/dl <2.5, generally the first punch holes, then reaming to obtain pore size requirements.

5 practical purposes

Perforated metal mesh can be used for lots across the city highway, railway, subway and other transportation facilities in the municipal environmental noise control barriers, architectural objects, walls, generator room, factory buildings, and other noise sources of acoustic noise with sound absorbing panels, can be used for the ceiling of the building, wall suction audio network, audio speaker mesh material that can be used for building stairs, balconies, green chairs beautifully decorated plate can be used for machinery and equipment, protective cover, ornate speaker grille, food, feed, grinding sieve used in mining, mining sieve, sieve the word,

Supplier's popular products

Send your inquiry to this supplier

Send Inquiry