1 / 4

Horizontal Autoclave for AAC Block Concrete Mixer Plant

$2000.00

≥1 Set/Sets

| Brand Name : | Yuanda |

|---|---|

| Applicable industry : | Construction Works |

Zhoukou, Henan, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

Product description

Horizontal Autoclave for AAC Block Concrete Mixer Plant

Industrial autoclaves is a kind of large steam curing pressure vessel and the key equipment to fabricate autoclaved aerated bricks and aerated concrete. Our high performance horizontal cylindrical aac block autoclave is made of high quality steel, autoclave for aac plant is widely used to steam fly ash brick, sand lime brick, slag brick, aerated concrete cut block, cement pile and other new lightweight wall materials. Our industrial autoclaves for AAC blocks is designed as per ASME Code which high levels of safety, high performance, flexibility process control and easy to operate.Industrial autoclaves is steeliness horizontal type, industrial autoclaves lid made of 16MnR steel plate, the body and cover of the autoclave made of 16Mn.

*Movable kettle doors;

*Mode of opening: manual & automatic;

*Steel horizontal cylinder-type device;

*Three forms of support: fixed, movable and special end support;

*Materials: kettle covers and cylinder made of Q345R steel plate;

*Equipped with safty valves, pressure gauges, temperature elements, INTAKE. EXHAUST valves, seals valve,draining valve, etc.

Industrial Autoclaves Applications:

Supercritical fluids (extraction, reactions)

Solubility and absorption measurements

Pyrolysis

Gasification of organic materials

Catalysis testing

High temperature corrosion studies

Gas adsorption / desorption (PSA, TSA)

Gas storage material testing

Gas separation

The autoclave reactor, also known as steam curing autoclave reactor, is a large and heavy pressure vessel and special equipment. Autoclave is widely used in autoclave curing of building material industry such as aerated concrete blocks, concrete piles, sand-lime brick, fly ash bricks, porous calcium silicate board, new lightweight wall materials, asbestos insulation, high strength gypsum, to complete hydrothermal reaction Cao-Si02-H2O in the reactor cylinder. It is also widely used in rubber products, wood drying and preservative treatment, heavy metal smelting, coal oil seepage firebrick invasion, high-strength glass autoclave curing, high pressure processing of chemical fiber products, high temperature high pressure processing of canned food, steam cooking of paper pulp, cable vulcanization, fishnet shape processing as well as in industries, for instance chemical , pharmaceutical, aerospace industry, insulation materials, textile, military etc. and other production projects that needs pressure steam autoclave curing process. Currently, China autoclave reactors and pressure vessels are mostly manufactured in Zhengzhou of Henan province and Changzhou of Jiangsu province, taking production technology imported from Germany.

| Specification(m) | Φ1.65×21 | Φ2×21 | Φ2.5×24 | Φ2.85×26 | Φ3×23 | |

| Rated Pressure(MPa) | 1.1/1.4 | 1.4 | 1.4/1.6 | 1.6 | 1.6 | |

| Design Temp(℃) | 187/195 | 195 | 195/204 | 204 | 204 | |

| Maximum Operating Pressure(MPa) | 1.0/1.3 | 1.3 | 1.3/1.5 | 1.5 | 1.5 | |

| Autoclave Inside track gauge (mm) | 600 | 600 | 800 | 600 | 915 | |

| Volume(m³) | 46 | 68 | 121 | 172 | 172 | |

| Weight(t) | 18.7/21.5 | 25 | 51/58 | 62 | 70 | |

| Dimension (m) | Length | 21.7 | 22.4 | 25.56 | 27.63 | 24.95 |

| Width | 2.62 | 3.05 | 3.25 | 3.58 | 3.65 | |

| Height | 2.6 | 3.3 | 4 | 4.49 | 4.85 | |

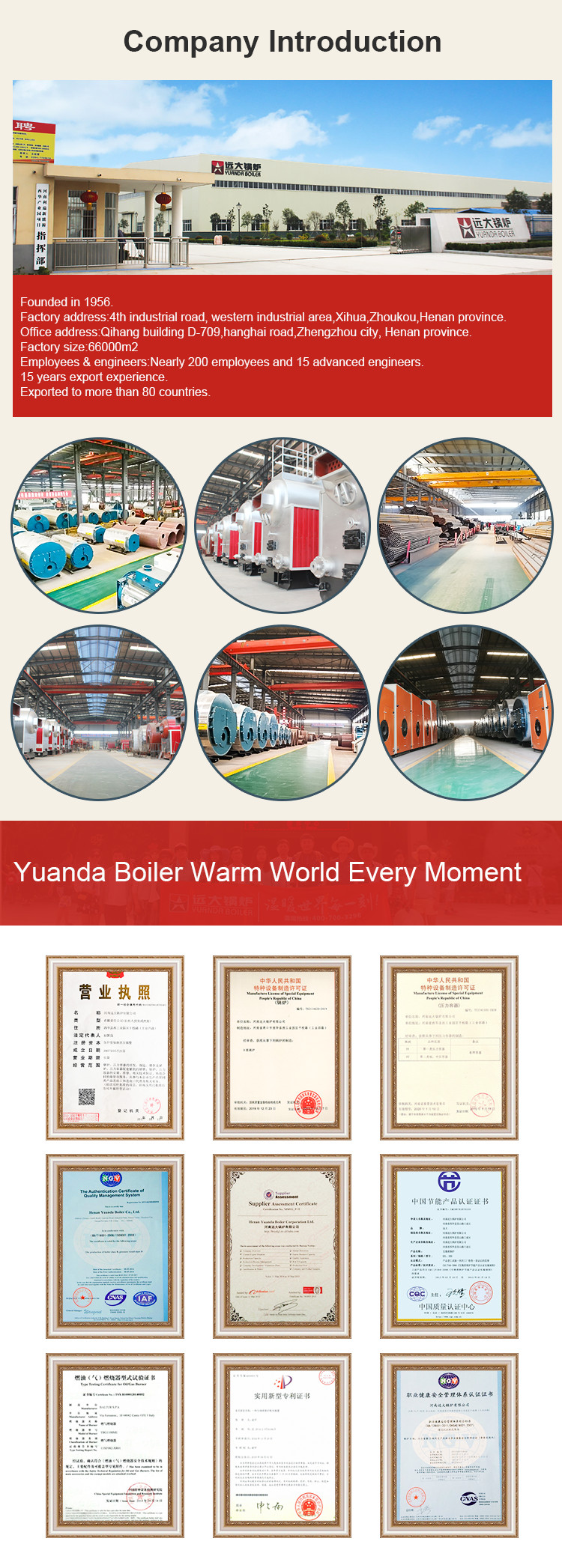

Henan Yuanda Boiler Co,. Ltd, founded in 1956, is one of the leading enterprises which firstly obtained boiler manufacturing license in China.

Our factory is located in the west industrial agglomeration area of Xihua county,Henan province. R & D center and marketing center are located in the capital city,Zhengzhou, Henan Province.We are high-tech enterprise combining with research, development and sales of heating system and power system. We have B-class boiler manufacturing license(professional for industrial boilers) and D-class pressure vessel manufacturing license, and passed ISO9001,ISO14001 and OHSAS18001.

The factory has beautiful environment with cover area 66000m2 and building area 30000m2. We have employees more than 200 people, including engineers 30 people and senior engineer 10 people. We have advanced equipment, with 430 sets of main production equipment and 30 sets of testing equipment.

We have our own R&D team and cooperate with famous high-tech research institutes at the same time , such as Beijing "Zhiguang" boiler institute,Harbin Institute of Technology and Xi'an Jiaotong University, which ensures our product and technology are in the forefront of technology and science. Till now, we have got more than 10 boiler patents.

Zhoukou, Henan, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

Send your inquiry to this supplier