1 / 4

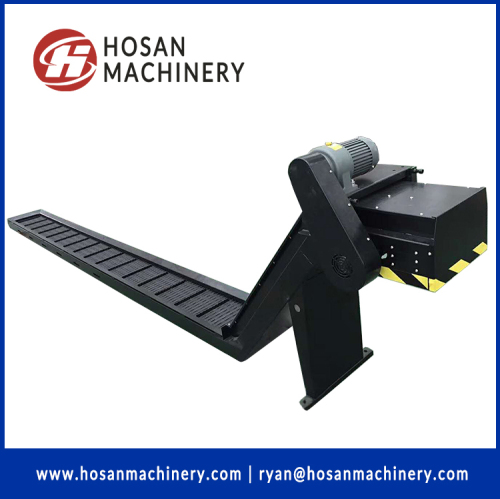

hinged belt copper swarf chips conveyor

| Model No. : | HS-018069213 |

|---|---|

| Brand Name : | Hosan |

| Material : | Stainless Steel |

Cangzhou, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

Product Description

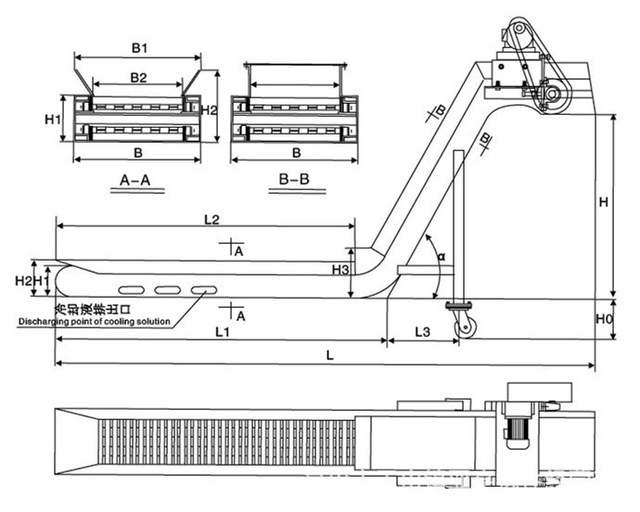

The scraper type chip removing device is driven by a speed reducing motor, and the chip is driven by the chain to scrape the chips deposited on the bottom plate of the chip discharging machine into the chip collecting car. The device has reliable operation, stable performance, quantitative chip removal, no noise and long service life.

The scraper type chip removing device is provided with a permanent magnet type magnetic field on the bottom plate of the chip discharging machine based on the scraping type chip discharging device, and the chips are first adsorbed on the bottom plate and then the scraping plate is forcibly scraped out. In wet processing, the scraper chip conveyor is the preferred model to replace the permanent magnet chip conveyor

scraper type chip conveyor is mainly used for separation and removal of non-agglomerate and fine debris with a length of not more than 150mm in dry or wet processing. It is suitable for various chip materials. The magnetic scraper type chip conveyor is mainly suitable for the conveying of short broken steel scraps and cast iron scraps by wet processing.

| Specification | Option | |||||

| Reduce Speed Motor | 1/4HP1/165 220/380V | CE Specification Device | Simple CE device of exit | |||

| Pitch of Chain | R 2050 P= 31.75mm | Full cover CE device of exit | ||||

| Scraped Width | 175,150-600 | Manual Control Device | standard/CE spec emergent stop | |||

| Scraped Device | One-three pieces for every 6 pitch | remote control boxes | ||||

|

|

||||||

| Scraped Speed | 1.2-1.4M/min(50/60HZ) | remote controller cable lines | ||||

| Safety Device | HTL-350-2 | Torque limit device | ||||

| Angle of Conveyor | 60° | prevent chips roll up device |

|

|||

Why Choose Us

1. With 30 years experience of hydraulic components in China.

2. Best manufacturing machinery, quality level, best price, best service.

3. We have very good and comprehensive after-sales service.

4. We have no MOQ for clients and tailor made to clients request for our huge inventory.

Our Service

Pre-sale service: we provide pre-sale in our first cooperation make clear your situation and give you some advice.

In-sale Service: We will track the production progress and quality, check the exact model and quantity one by one before delivering.

After-sale Service: We will provide a one year free warranty and lifetime maintenance. We will change all questions in 7*24hours if you buy from us.

Packing

Eternal Brand, Neutral or Customer's requires label.

Neutral carton or same as the Customer's requires, export standard carton.

All cartons should be packed into the pallets more carefully.

All of the productions are inspected carefully one by one by QC before delivery.

Payment term:

T/T 50% as deposit in advance, the balance should be paid before delivery.100% L/C is acceptable.Western Union and PayPal is acceptable.

Transportation: By sea; By air; By truck; By express (DHL,TNT,UPS,FEDEX)

Trading term: FOB,FCA,CIF

FAQ

Question 1: Did you accept products customization? Do they need mould fee?

Answer: Yes, we accept products customization. Need mould fee, because products usually need extra mould cost.

But we can return the mould fee when order reach a specific quantity.

Question 2: Can we get free samples?

Answer: The sample expense and freight expense will be borne by the buyers, and will be returned in the following orders.

Question 3: How long is normal production period for a 20-foot shipping container?

Answer: Accoring to the current productive capacity, usually need 3-14 days from producing to delivery. (not including customized products)

Question 4: What is the type of payment?

Answer: Usually, you should prepay 50% of the total amount. The balance should be paid before delivery. (We'll send photos of product to you for checking before delivery)

Question 5: How to guarantee the high quality?

Answer: We have testing department to make sure quality of every product, appearance and pressure test are good.

Cangzhou, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier