1 / 3

High Thermal Conductivity Alumina Ceramic Plate / Substrate

| Model No. : | MRT-64 |

|---|---|

| Brand Name : | Mingrui |

| Color : | White,yellow |

Product description

Product Description:

High Thermal Conductivity Alumina Ceramic Plate / Substrate

This Alumina ceramic Substrates is characterized by its extremely high strength and thermal conductivity. The outstanding surface quality on both sides makes it the perfect companion for any commercial thick film paste and even makes it suitable for a number of thin film applications (sputtering).

With Its extremely fine surface quality, Alumina Ceramic Substrates is designed especially to meet the highest demands in thin-film technology.

Alumina Ceramic Substrates offers consistently reliable and convincing performance even when subject to high thermal and electrical loads in terms of its:

Thermocycling capability

Thermal shock resistance

Flexural strength

Surface quality

Thermal conductivity

We can make any thickness as you need from 0.25 to 1.2mm. Max length we can provide is 280mm.

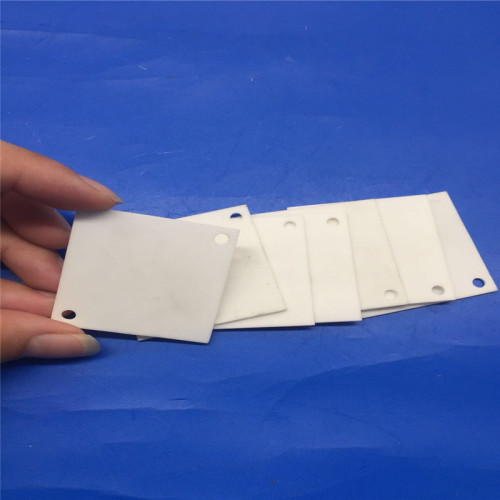

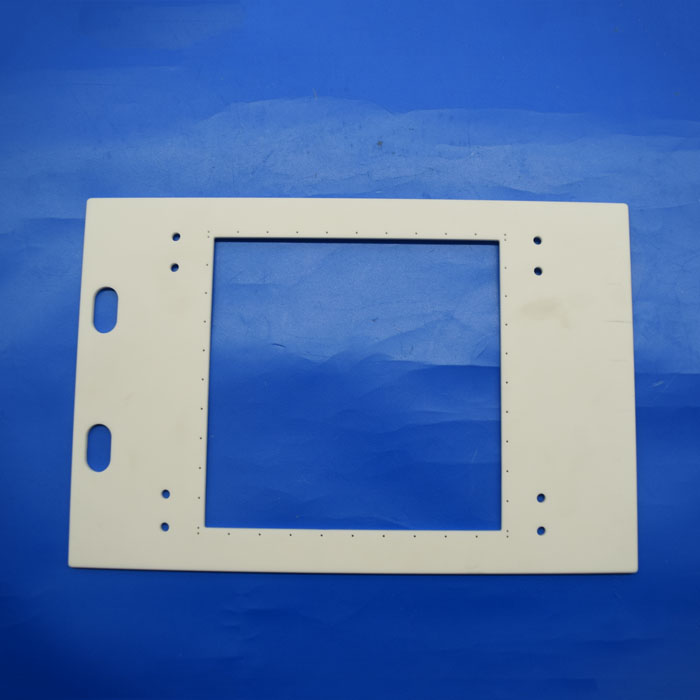

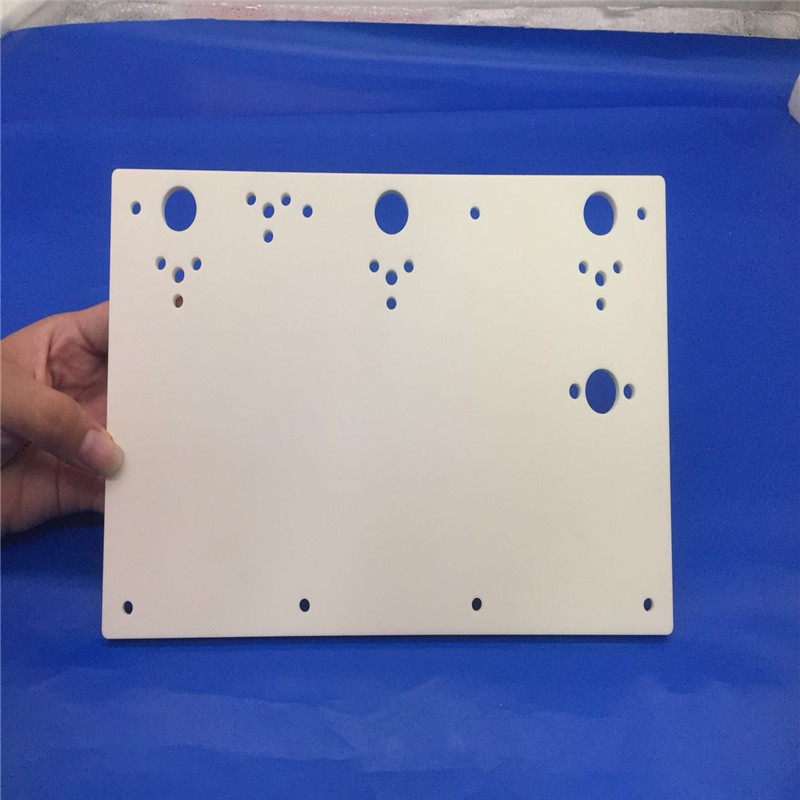

Detailed Image

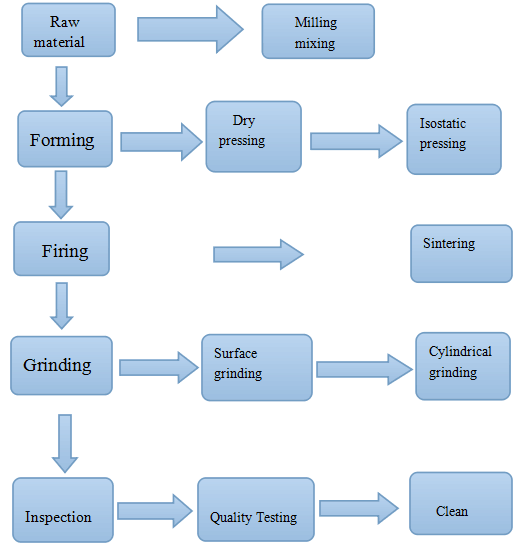

production process

Production range:

Mingrui offers you a wide range of production facilities like extrusion, injection moulding, pressing and casting. Depending on product geometry and quantities, we will choose the suitable technique for your products.For the final finishing of the parts we use CNC machining centres, equipped with diamond tools in order to meet high accuracies.

Our aim is to offer the ideal solution for any application. Our engineers therefore offer custom solutions that range beyond our existing product portfolio. With our well-equipped industrial development facilities, we produce innovations that can be rapidly commercially exploited

The range of products we can make is:Alumina ceramic, Zirconia ceramic , Ceramic Dowel pin, Zirconia Positioning pin, Insulating ceramic plate,Ceramic roller,Ceramic blade,Ceramic brackets,Ceramic disc,Ceramic insulator,Ceramic rod,ceramic atomizer,ceramic nozzle,ceramic necklace, ceramic pin, ceramic bushing, ceramic washer, zirconia ceramic plate, ceramic insert, white ceramic ring, ceramic shaft,ceramic pump, ceramic piston, , machinable ceramic, ceramic arms and so on.

The products made by zirconia and alumina products have excellent performances,the properties of our products:

|

Properties |

Units |

95 Alumina |

99 Alumina |

ZrO2 |

|

Density |

g / cm³ |

3.65 |

3.9 | 5.95-6.05 |

|

Water absorption |

% |

0 | 0 | 0 |

|

Coefficient of thermal expansion |

10-6/K |

7.9 |

8.5 | 10.5 |

|

Modulus of Elasticity Young's Mod |

GPa |

280 | 340 | 210 |

|

Poisson's ratio |

/ | 0.21 | 0.23 | 0.3 |

| HV Hardness |

MPa |

1400 | 1700 | 1300-1365 |

|

Flexural Strength @ room temperature |

MPa |

280 | 320 | 950 |

|

Flexural Strength @700°C |

MPa |

220 | 230 | 210 |

|

Compressive Strength @ room temperature |

MPa |

2000 | 2200 | 2000 |

|

Fracture Toughness |

MPa *m 1/2 |

3.8 | 4.3 | 10 |

|

Heat conductivity @ room temperature |

W/ m*k |

18-25 |

26-30 |

2-2.2 |

|

Electrical Resistivity @ room temperature |

Ω*mm2 /m |

10^15 |

10^16 |

10^15 |

|

Max use temperature |

°C |

1850 | 2200 | 1500 |

|

Resistance to acid alkaline |

/ |

high |

high |

high |

|

Dielectric Constant |

/ |

9.5 | 9.8 | 26 |

|

Dielectric Strength |

KV/mm |

10 | 10 | 10 |

|

Thermol Shock Resistance |

△ T ( °C ) |

220 | 190 | 280-350 |

|

Tensile Strength @ 25 °C |

MPa |

200 | 248 | 260 |

|

Thermal Conductivity(25℃) |

W/m·K |

30 | 35 | 3 |

Workshop overview:

We have almost all the precision processing machines of ceramic products:

Quality assurance:

We have complete testing equipment and good after-sales service:

Our certifications:

Delivery:

we will give you quick response to solve your problems at the first time. we also improved our logistics service system so that you can enjoy a one to one intimate service.Each of our product is elaborately packed to insure it is intact when arriving;We cooperate with professional logistics such as DHL UPS,Fedex,etc.and offer realtime tracking data to our customers in time.

FAQ;

1.are you manufacturer or trade company?

We are a factory with our own workshop located in Chang'an Town ,Dongguan City,which is known as

[The hometown of mould",We have strong precision processing ability and excellent matching manufacturer.

2.Can you provide the free samples?

Yes, we can provide the sample free of charge if we have the stock product as customer's requirements, but the freight is on your side.

3.Can you accept OEM&ODM?

Yes, we can produce the products according to your demand and drawing.

Send your inquiry to this supplier