1 / 4

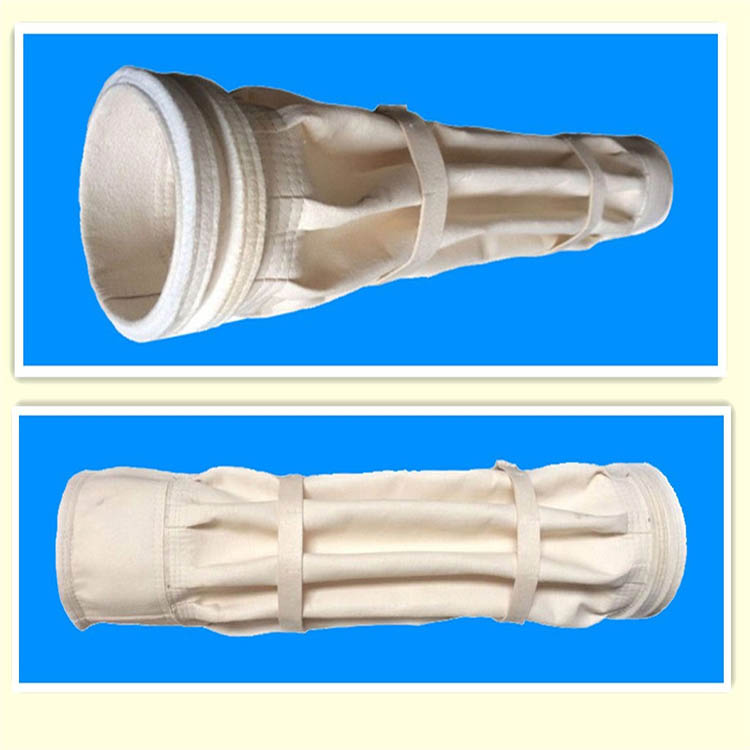

High temperature flue gas industry cloth bag

| Model No. : | Customized |

|---|

Product description

1. Application of glass fiber filter material in cement industry

Cement industry is the earliest and most widely used industry. In the middle and small cement plants, the temperature of the flue gas from the shaft kiln and the dryer are higher. The experts of the cement research and Design Institute have targeted the development of the dust collector of the glass fiber bag in the vertical kiln, the glass fiber bulge filter material which is cheap and beautiful, and the continuous filter material of glass fiber, used in the dust remover of the shaft kiln and the dryer. China's shaft kiln has a large volume, and in the past accounted for more than 80% of the cement output. Now it also accounts for about 40%, and cement output also reaches 5 billion tons. Thousands of enterprises, thousands of vertical kilns, used a large number of fiberglass bulked yarn filter material. With the passage of time, the cement industry in China has changed greatly, and it pays more attention to environmental protection. The quantity of the cement in the vertical kiln will be greatly reduced, and the amount of glass fiber filter material in this respect will also shrink greatly. The new dry cement production line has developed very fast in recent years. The production line of 5000t/d was only about 10 before 2000. In 2006, the production line of 5000t/d was about 200, and each line adopted the bag type dust collector more than 50. The electrostatic precipitator was used mainly in the dust removal of kiln head and kiln tail. After the national standard of flue dust emission concentration of the kiln tail dust collector was revised to less than 50mg/m3, more and more bag type dust remover was used in the kiln head and kiln tail. In 2007, most of the kiln heads and the end of the kilns used bag filters. Only a few of the two or three cement enterprises still used electrostatic precipitators. In many places, the electrostatic precipitator that can not be discharged is transformed into a bag filter or electric bag filter. The flue gas quantity of the kiln tail bag filter in 5000t/d is nearly 1 million m3/h, and the filter material is more than 15000m2. Most of the imported glass fiber coated filter material (domestic glass fiber film filter material begins to enter the kiln head and the kiln tail bag type dust collector), and a few of the P84 filter materials are used. The space of domestic glass fiber coated filter material for kiln head, kiln tail and clinker grinding bag filter is very large, and the market prospect is considerable.

Send your inquiry to this supplier