1 / 1

High Quality Aluminum CNC Machining Part

| Model No. : | Aluminum CNC Machining Part -001 |

|---|---|

| Brand Name : | Opoint |

Product description

1. Alloy

2. Finish: Mill, anoidized, powdercoated

3. OEM and ODM

4. SGS

High Quality Aluminum CNC Machining Part Product Description Material Composition

| Grade | 1050 | 1060 | 1070 | 3003 | 5052 | 6061 | 6063 | 6463 | |

| Standard | GB/T 3190-1996 | ||||||||

| Al | 99.5 | 99.6 | 99.7 | Remain | Remain | Remain | Remain | Remain | |

| Si | <=0.25 | <=0.25 | <=0.20 | <=0.60 | <=0.25 | 0.4~0.8 | 0.20~0.6 | 0.20~0.6 | |

| Cu | <=0.05 | <=0.05 | <=0.04 | 0.05~0.20 | <=0.1 | 0.15~0.4 | <=0.10 | <=0.20 | |

| Mg | <=0.05 | <=0.03 | <=0.03 | - | 2.2~2.8 | 0.8~1.2 | 0.45~0.9 | 0.45~0.9 | |

| Zn | <=0.05 | <=0.05 | <=0.04 | <=0.10 | <=0.1 | <=0.25 | <=0.10 | <=0.05 | |

| Mn | <=0.05 | <=0.05 | <=0.03 | 1.0~1.5 | <=0.1 | <=0.15 | <=0.10 | <=0.05 | |

| Ti | <=0.03 | <=0.03 | <=0.03 | - | - | <=0.15 | <=0.10 | - | |

| V | <=0.05 | - | <=0.05 | - | - | - | - | - | |

| Fe | <=0.40 | <=0.35 | <=0.25 | <=0.70 | <=0.4 | <=0.7 | <=0.350 | <=0.15 | |

| Cr | - | - | - | - | 0.15~0.35 | 0.04~0.35 | <=0.10 | ||

| Other | Single | - | - | - | 0.05 | 0.05 | - | 0.05 | 0.05 |

| Total | - | - | - | 0.15 | 0.15 | - | 0.15 | 0.15 | |

Item | Aluminum CNC Machining Part |

Model | Aluminum CNC Machining Part-001 |

HS Code | 7604 |

Surface Treatment | Anodic Oxidation |

Temp | T3-T8 |

Grade | 6000 series |

Standard | GB/T 3190-1996 |

Size | 80 |

Technique | Extruded |

Shape | T - Profile |

Application | Heatsink |

Certificate | SGS |

MOQ | 300 KG |

Price | USD3~6/KG |

Delivery Time | According to products |

| Mill finish | Finish of aluminum itself, with a natural anodic layer formed in the air, week corrosion resistance |

| Anodizing | Through an eletrical process to form a certain layer of anodic layer on the surface of profile, available in different colors, including silver, champagne, dark bronze, golden, black |

| Eletropharesis | Base on anodized process, an extra transparent film is formed to make the surface clearer and look bit of shining, with very good corrosion resistance. |

| Powder coating | The powdered paint is electrostatically charged and sprayed onto the part, to form a thick layer to protect the surface. With very good corrosion resistance, available in all kinds of colour |

| Wooden grain | New technology in finishing to form a texture look like real wood. Handtouch or film transfering are both available |

| Polishing | By buffing and chemical process to form mirror like finish, suitable for decorative application |

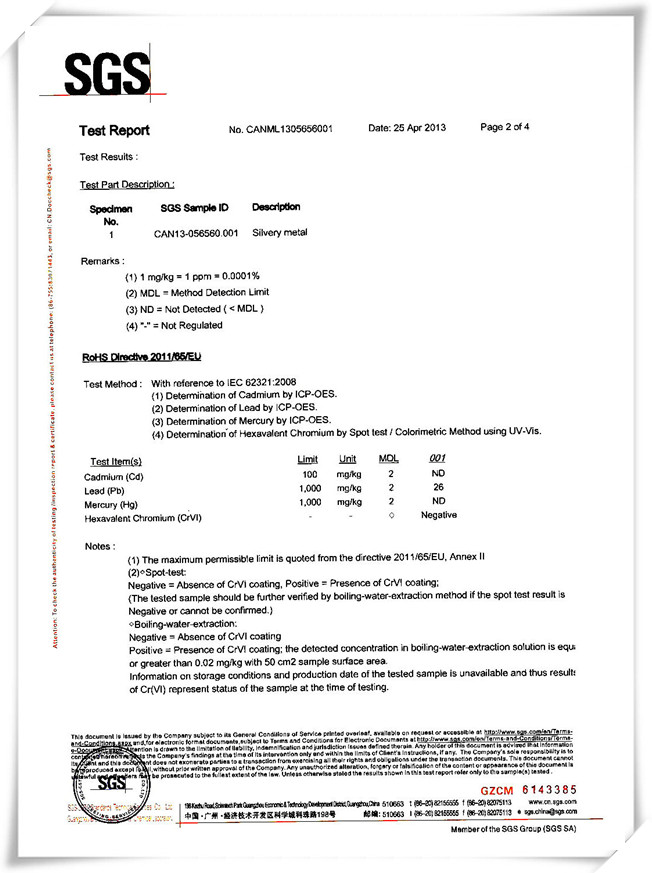

Certificate

Certificate  Packaging & Shipping Packaging EPE, PVC inner bag, then Wooden Pallets

Packaging & Shipping Packaging EPE, PVC inner bag, then Wooden Pallets  Payment ---Payment terms: Western Union, T/T,L/C ---Please remember to leave the correct contact information for delivery.

Payment ---Payment terms: Western Union, T/T,L/C ---Please remember to leave the correct contact information for delivery.  Shipment ---Shipping terms: DHL, UPS, FEDEX, TNT, EMS ---Port is Foshan, Huangpu, Shenzhen or as requests.

Shipment ---Shipping terms: DHL, UPS, FEDEX, TNT, EMS ---Port is Foshan, Huangpu, Shenzhen or as requests.  Our Services Sample Sample Fee: Negotiate Samples: Available for evaluation before place order. Sample Time: According the products Services 1. We're a well-established manufacture for aluminium products,having been in this line for 10 years,we're confident we can give our customers complete satisfication. 2. We can provide good quality with reasonable price 3. We can produce what size and shape of such heat sink you want. Company Information Opoint Aluminum LTD. is specialized in producing aluminum extrusion products used for architectural, decorative, medical equipment, industrial and other purposes, such as assembled parts of equipment, ladders, accessories of window and doors, shower rooms and furniture, aluminum hinges, heat sinks, frames, dryers, and so on.

Our Services Sample Sample Fee: Negotiate Samples: Available for evaluation before place order. Sample Time: According the products Services 1. We're a well-established manufacture for aluminium products,having been in this line for 10 years,we're confident we can give our customers complete satisfication. 2. We can provide good quality with reasonable price 3. We can produce what size and shape of such heat sink you want. Company Information Opoint Aluminum LTD. is specialized in producing aluminum extrusion products used for architectural, decorative, medical equipment, industrial and other purposes, such as assembled parts of equipment, ladders, accessories of window and doors, shower rooms and furniture, aluminum hinges, heat sinks, frames, dryers, and so on.Our production process includes extrusion, sawing (cutting), punching, milling, lathing, drilling, tapping, polishing, sliding, shot blasting, CNC, anodizing, powder coating and PVDF coating with various colors.

"Customer satisfaction" is our object and "making friends from all over the world" is our life. Please feel free to contact us for further information. Factory

Equipment

Equipment

Our Team

Our Team  Exhibition

Exhibition

Send your inquiry to this supplier