Video

1 / 4

High Production Silicone Cover Injection Making Machine

$4500.00

≥1 Set/Sets

$3000.00

≥2 Set/Sets

| Model No. : | JY-B01 |

|---|---|

| Brand Name : | JINYU |

| Core components : | Engine,Motor,Pump,Pressure Vessel |

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Product description

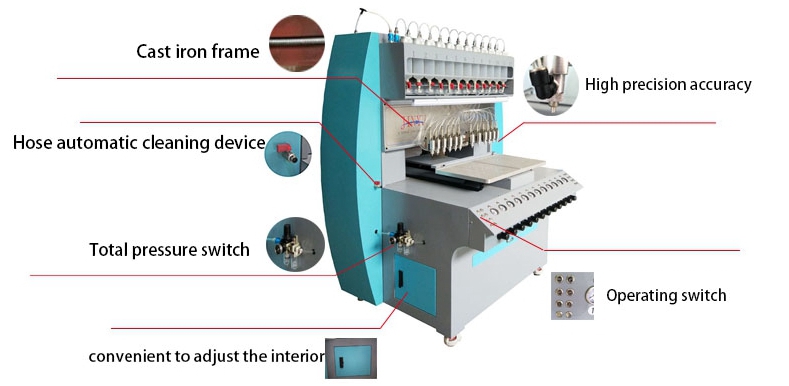

High Production Silicone Cover Injection Making Machine

High Production Silicone Cover Injection Making Machine configuration can be packed in 8 different colors, each hose can operate independently, improve production efficiency, rubber hose can be 360 ° rotation.

Specification:

| Model |

JY-B02 |

|

Repeat positioning control precision |

+-0.01 |

|

Transport system |

Servo motor screw drive |

|

Worktable size |

550*300 mm |

|

Power supply |

Single phase 220 v/50 HZ |

|

Dispensing needle |

8 |

|

Total power |

1.2 kw |

|

Work stroke |

X-350 mm Y-300 mm Z-40 mm |

|

Weight |

500 kg |

|

Speed |

6 m/min |

|

Spit frequency times/min |

800 |

|

Machine size |

900*1050*1450 mm |

Main Features:

1. Three-axes linkage, support high-speed continuous interpolating of any 3D curve, the speed reaches 999 mm/s.

2. High-speed ladder-shaped acceleration and deceleration, handle the continuo speed based on speed forecasting technology.

3. Repeat positioning control precision can reach 0.5 pulse.

High efficiency procession control:

1. Cooperating high speed movement with the sync glue head and double-sided cycle file procession. you can make the best use of the machine.

2. Choose the file with the shortcut button, can realize compels multiple dispensing procession.

Perfect programming support:

1. Humanized software design idea, easy for study and use.

2. Excellent compatibility, support many design software(including JD paint, Auto CAD, Coreidraw) and various file form-wt which generated. In addition, it also support scanning and teaching programming, without and limit on the graphic track planning.

3. Fast parameter setting and debugging, connection with PC, can amend the graphic immediately, and run it right now.

Application:

label , keychain , rubber patch , fridge magnet , luggage tag , photo frame , bar mat , floor mat , car mat , small mat , hair clip , brooch , coasters , mobile phone strap , moblie phone holder , key holder , USB case , zipper puller etc.

Service:

Pre-sale service:

1. We offer the mechanical parameters and the analysis of the machine for you.

2. You may obtain the ex-factory price of the machine.

3. Welcome to visit our factory and training.

After-sale service:

1. Send technicians abroad maintenance.

2. Free training service.

3. 24hours and whole year service without vacation.

4. We will set files for the old and new machine,and provide service for the hydraulic machine of other factory.

5. All sold machine will be provided with warranty of one year.

6. free warranty of one year ,and maintenance all life of machine,and the service will be provided in your company.If you meet with any problem about the machine.

Company View:

Dongguan Jinyu Automation Equipment Co.,Ltd. is founded in 2000, located in xiangdong industrial area, mainly dealing with silicone, pvc trademarks gifts making equipment, in a short few years, from guangdong pearl river delta to whole coastal area of China, jinyu equipment is all over this industrial, jinyu got the industry's highly recognized. As to reduce the environmental damage,we found silicone industrial, it is environment protection an no harm to human, it is the best choose.

Jinyu research and developed full automatic dispensing machine, special silicone /rubber dropping, full automatic vulcanizing machine, is the best foundation of the industrial, jinyu equipment have the features of labors saving, saving electricity, saving management.

Package & Shipment:

FAQ

Q; Are you trading company or manufacturer

A: We are industry and trade integration, provide the whole set of silicone machines, pvc machines, kpu machines. With more than 20 years experience in the industry, already serve all over the world.

Q: How long is your delivery time

A: Generally for 25 days delivery.

Q: Can you provide technical support

A: We provide free training from 2 to 3 weeks.

Q: How to help when machine wrong

A: Generally, we will send the damaged parts by post.

Q: Can produce customized products

A: We can produce customized products for you.

Q: Why you choose Dongguan Jinyu Automation Equipment Co., Ltd.

A: We have independent research and development of products, enhance mechanical efficiency every day. Jinyu Machinery, brand TUA, our machines have spread all over the world.

Video

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier