Video

1 / 1

High-precision Gear Hobbing Machines 3110CNC7

| Model No. : | Y3110CNC7 |

|---|---|

| Brand Name : | TOMAN |

| place of origin : | China |

Product description

Zhejiang TOMAN Intelligent Technology Co., Ltd. was founded in 2006, mainly engaged in the research and developments, manufacturing and service of Gear Automation Equipments, Bearing Automation Equipments, Intelligent Components、Industrial Internet Application and System Integration based on Industry 4.0.

TOMAN is committed to being a leader in the professional gear manufacturing field and creating wealth for customers and society.

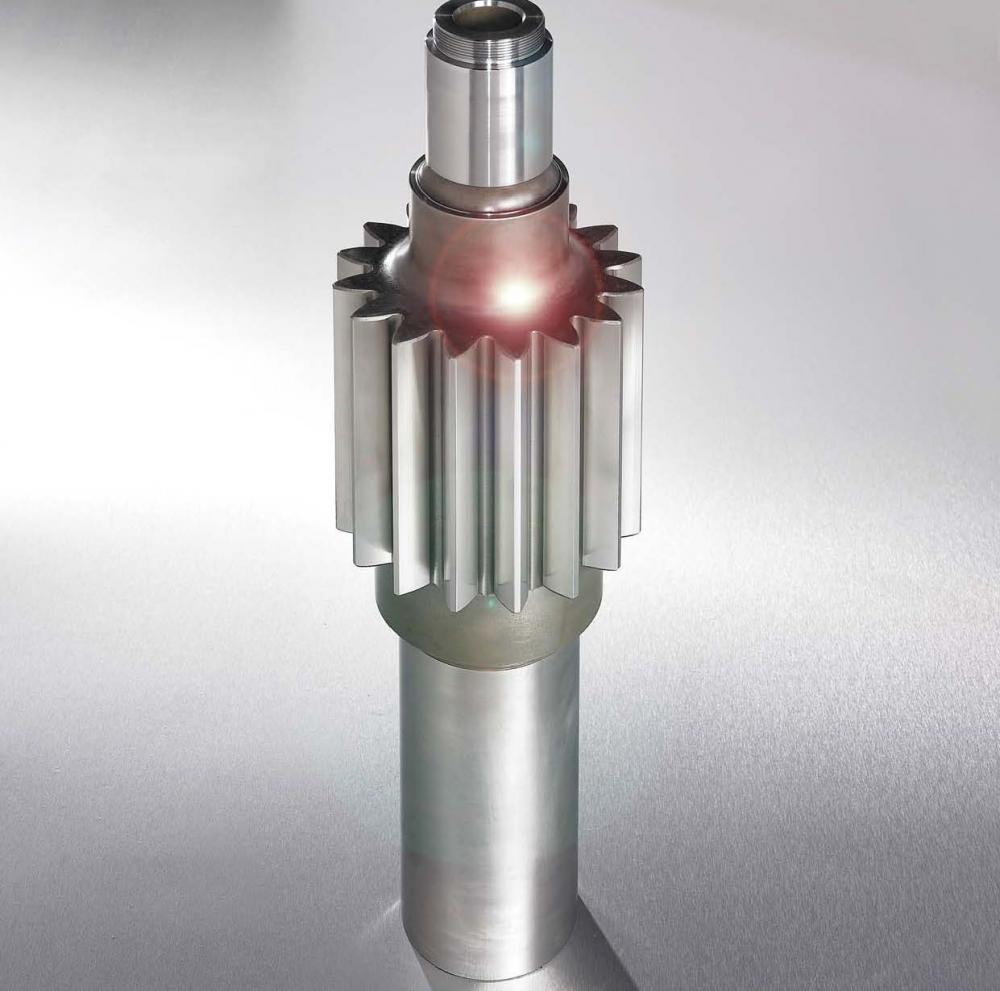

Y3110 CNC7 Hobbing Machines are vertical hobbing, which are capable of producing disc gear, shaft gear, helical gear and small taper tooth, drum gear, spline, worm gear, sprocket, double or multi-linkage gear with different modules,teeth number, helical angles and directions.

Customers can choose automatic loading and unloading device, automatic material storage machine, burring device ,coarse positioning device according to the processing demands.

Y3110 CNC7

An Engery Saving and Complete Dry Cut Hobbing Machine

FANUC numerical control system and servo drive, system reliability, simple operation

Automatic loading/unloading material device

(Dry Cutting Hobbing Machine or Wet/Dry Cut Hobbing Machine is optionally available.)

|

Max. Workpiece Diameter: Φ100 mm |

|

Max. Module: 3 |

Main Technology Parameter

|

CNC hobbing machine |

Unit |

TMY3110 |

|

|

|

Dry hobbing |

|

Maximum workpiece diameter |

mm |

Φ100 |

|

Maximum module |

mm |

3 |

|

Worktable surface diameter |

mm |

Φ150 |

|

Hob maximum assemble diameterx length |

mm |

Φ110x150 |

|

Horizontal distance between hob center and worktable center |

mm |

5-145 |

|

Maximum hob axial movement amount |

mm |

130 |

|

Hob head slide travel (Z axis displacement) |

mm |

190-400 |

|

Max. swiveling angle of the hob head |

Deg |

±45° |

|

Hob spindle motor power |

KW |

7.5 |

|

Maximum hob spindle rotate speed(B axis) |

rpm |

3000 |

|

Maximum worktable rotate speed(C axis) |

rpm |

400 |

|

Radial feed speed(X axis)(stepless) |

mm/min |

1-2000 |

|

Radial maximum rapid moving speed(X axis) |

mm/min |

8000 |

|

Axial feed speed(Z axis)(stepless) |

mm/min |

1-2000 |

|

Axial maximum rapid moving speed(Z axis) |

mm/min |

8000 |

|

Tangential travel feed speed(Y axis)(stepless) |

mm/min |

1-1000 |

|

Tangential maximum rapid travel speed(Y axis) |

mm/min |

3000 |

Standard Configuration

|

Hob arbor assembly ( Φ32) |

hydraulic system |

|

Hob arbor automatic clamping device |

NC controller system |

|

Workpiece automatic clamping device |

NC data memory card |

|

Spindle positioning |

Operational software |

|

Fully-enclosed safeguards |

Residual-current circuit breaker |

|

Woking light |

Hands action button |

|

Three colour lights indicate machine status |

RS232C connector |

|

Workpieces counter |

Air conditioner for electric cabinet |

|

Main spindle ampere meter |

Chip conveyor |

|

Chip cart |

Automatic lubrication system |

|

Cutting oil tank (Wet hobbing ) |

Mist collector |

|

Cold spray gun (Wet hobbing ) |

The sizing block for machine adjustment |

Optional Configuration

|

Automatic loading/unloading material device |

Workpiece clamping |

|

Automatic material storage |

Workpiece rough locator device |

|

Deburring device |

Automatic tooth align device |

|

Independent hob adjustment device |

Oil cooling device |

|

Hob arbor assembly:(metric system:Φ10, Φ13, Φ22, Φ27, Φ40),(Inch system: Φ16, Φ22.225, Φ26.988, Φ38.1) |

|

Application:

-

Steering Pinion;

- Geared Motor;

- Compact Reduction Gear;

-

Motorcycle Gear etc.

Main Features

6. The dual-station loading and unloading manipulator design of the processing position and the replacement position, compact and reliable structure, which saves the loading and unloading time to the greatest extent, and realizes less and unmanned processing, to improve the processing efficiency of the machine tool.

Video

Send your inquiry to this supplier