Video

1 / 5

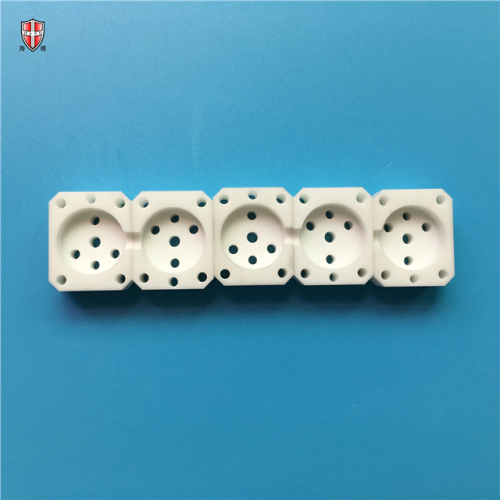

high precision custom alumina ceramic machined parts

$3.00

≥10 Piece/Pieces

$1.00

≥100 Piece/Pieces

$0.50

≥1000 Piece/Pieces

$0.10

≥10000 Piece/Pieces

| Model No. : | Al2O3 340 |

|---|---|

| Brand Name : | Hard |

| place of origin : | China |

Shenzhen, Guangdong, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Product description

high precision custom alumina ceramic machined parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Compared with blast furnace slag, alumina desiliconization slag has high iron oxide content, and the original Al2O3-SiC-C type iron groove refractory material is seriously eroded in the slag line. Therefore, the material is changed in the slag line, the size of the molten iron groove is expanded in the desiliconizing agent, and the forced air-cooling tube is buried in the side wall of the iron groove. The desiliconized slag of the high iron oxide is eroded due to oxidation of SiC and C. It can be replaced by Al2O3-MgO refractory material, and the corrosion resistance mainly depends on the amount of liquid phase formed by the slagging reaction. The experiment confirmed that when MgO/Al2O3>1, the formation of the liquid phase was inhibited because the reaction of FeO with Al2O3-MgO in the desiliconized slag produced high-melting minerals. It is generally believed that the thermomechanical damage of the sintered refractory oxide product is mainly caused by microcracks, and the generation and growth of the microcracks depend on physical strengths such as strength, elastic modulus, thermal conductivity, and linear expansion coefficient of the product. For sintered products, the higher the high temperature strength, the smaller the factors that inhibit crack generation, the existing microcracks tend to grow, the fracture toughness is poor, and the cracks are easily broken at high temperatures. The high-temperature alumina is fired into refractory products such as burnt magnesia bricks. The key weakness of the calcined magnesia-chrome bricks is that the thermal shock resistance is poor and the defects of the slag are easily absorbed. Under the premise of determining the material and the binder, it is essential to produce a high-quality spray material, and the particle size ratio of the aggregate is essential. The critical particle size is large, and the corrosion resistance is good, but the fluidity is poor and the rebound rate is high in the spray filling operation. The critical particle of the semi-dry spray is usually 3 mm.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Video

Shenzhen, Guangdong, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Send your inquiry to this supplier