1 / 4

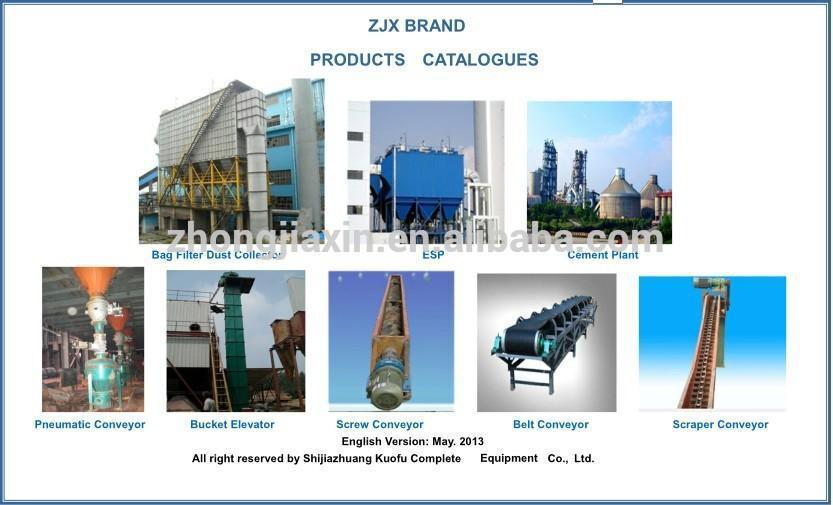

High performance Industrial Bag Filter for exhaust gas processing

| Model No. : | PPCS |

|---|---|

| Brand Name : | ZJX |

Product description

Note :We design dust collecting system with different air capacity as specific requriement.

Note :We design dust collecting system with different air capacity as specific requriement. Parameters of bag filter for your reference :

Model parameters | Air Capacity(m³/h) | Gross filtration area(m³) | Net filtration area(m³) | Chamber quantity | Filter bag | |

quantity | specification | |||||

PPCS32-3 | 6900 | 93 | 62 | 3 | 96 | 130×2450mm |

PPCS32-4 | 8930 | 124 | 93 | 4 | 128 | |

PPCS32-5 | 11160 | 155 | 124 | 5 | 160 | |

PPCS32-6 | 13390 | 186 | 155 | 5 | 192 | |

PPCS64-4 | 17800 | 248 | 186 | 4 | 256 | |

PPCS64-5 | 22300 | 310 | 248 | 5 | 320 | |

PPCS64-6 | 26700 | 372 | 310 | 6 | 384 | |

PPCS64-7 | 31200 | 434 | 372 | 7 | 448 | |

PPCS64-8 | 35700 | 496 | 434 | 8 | 512 | |

PPCS96-4 | 26800 | 372 | 279 | 4 | 384 | |

PPCS96-5 | 33400 | 465 | 372 | 5 | 480 | |

PPCS96-6 | 40100 | 557 | 465 | 56 | 576 | |

PPCS96-7 | 46800 | 650 | 557 | 7 | 672 | |

PPCS96-8 | 53510 | 744 | 650 | 8 | 768 | |

PPCS96-9 | 60100 | 836 | 744 | 9 | 864 | |

PPCS96-2×5 | 66900 | 929 | 836 | 10 | 960 | |

PPCS96-2×6 | 80700 | 1121 | 1028 | 12 | 1152 | |

PPCS96-2×7 | 94100 | 1308 | 1251 | 14 | 1344 | |

PPCS96-2×8 | 107600 | 1494 | 1401 | 16 | 1536 | |

PPCS96-2×9 | 121000 | 1681 | 1588 | 18 | 1728 | |

PPCS96-2×10 | 134500 | 1868 | 1775 | 20 | 1920 | |

PPCS128-6 | 67300 | 935 | 779 | 6 | 768 | 130×3060mm |

PPCS128-9 | 100900 | 1402 | 1246 | 9 | 1152 | |

PPCS128-10 | 112100 | 1558 | 1402 | 10 | 1280 | |

PPCA128-2×6 | 134600 | 1869 | 1713 | 12 | 1536 | |

PPCA128-2×7 | 157000 | 2181 | 2025 | 14 | 1792 | |

PPCA128-2×8 | 179400 | 2492 | 2336 | 16 | 2084 | |

PPCA128-2×9 | 201900 | 2804 | 2648 | 18 | 2304 | |

PPCA128-2×10 | 224300 | 3115 | 2959 | 20 | 2560 | |

PPCA128-2×11 | 247600 | 3427 | 3271 | 22 | 2816 | |

PPCA128-2×12 | 269100 | 3738 | 3582 | 24 | 3072 | |

PPCA128-2×13 | 294600 | 4050 | 3894 | 26 | 3328 | |

PPCA128-2×14 | 314000 | 4361 | 4205 | 28 | 3584 | |

Principle of bag filter : A bag filter is a dust collection device using a woven or non-woven filter bag that filters and collects the dust in process gas. When the filter cloth is made into a cylindrical-shaped bag and suspended, it is referred to as a baghouse or a fabric filter.The inside of a large fabric filter is divided into several compartments. Each compartment contains several filter bags in which filter cloth sewn into cylindrical shapes is installed. A hopper is provided in the bottom of the compartment to collect the dust removed from the filter bags.. It is important to select the filter material of a filter bag to suit the gas temperature, humidity, gas composition, and dust characteristics. The life of a filter bag is several years, but varies greatly depending on the gas and dust characteristics. The equipment cost of a fabric filter is lower than that of an electrostatic precipitator, but the maintenance cost of replacing the filter bag, etc., and the operating cost of the system fan to compensate for the pressure loss is somewhat larger. Fabric filters are widely used as the dust collection systems for industrial processes with a medium or low quantity of process gas. Main parts of bag filter :

\

\  Packaging & Shipping We test dust collector before it is packaged and transported: Packaging and transporting: we usually use composite material box or steel box to package the easy damage parts, we can also do as the customer's request.

Packaging & Shipping We test dust collector before it is packaged and transported: Packaging and transporting: we usually use composite material box or steel box to package the easy damage parts, we can also do as the customer's request.  Our Services We have strong technology term and installation personnel, we are able to design and manufacture the machines with different capacity. Consult → design → process planning → production → quality control → test → package → delivery → installation → commissioning → training Quality Assurance: 12months Quality warranty period (after put into operation formally). Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. All the machines provided by our factory will be tested before ship. Company Information Shijiazhuang Kuofu Complete Machinery Equipment CO.,Ltd is established in the year of 2002 and located in Shijiazhuang, Hebei Province where is near Beijing and Tianjin. It is important to design the fabric filter and select the filter cloth to suit the properties of the process gas and dust. We use our rich experience and knowhow to supply highly reliable fabric filters that take plant system status into account and have sufficient dust collection performance to meet customers' needs.

Our Services We have strong technology term and installation personnel, we are able to design and manufacture the machines with different capacity. Consult → design → process planning → production → quality control → test → package → delivery → installation → commissioning → training Quality Assurance: 12months Quality warranty period (after put into operation formally). Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. All the machines provided by our factory will be tested before ship. Company Information Shijiazhuang Kuofu Complete Machinery Equipment CO.,Ltd is established in the year of 2002 and located in Shijiazhuang, Hebei Province where is near Beijing and Tianjin. It is important to design the fabric filter and select the filter cloth to suit the properties of the process gas and dust. We use our rich experience and knowhow to supply highly reliable fabric filters that take plant system status into account and have sufficient dust collection performance to meet customers' needs. Certification:

Quality Certification of ISO9001:2008

Patent of Dust Humidifier

FAQ 1. Q: Are you a manufacturer or trading company? A: We are manufacturer, also have our own trading company .

FAQ 1. Q: Are you a manufacturer or trading company? A: We are manufacturer, also have our own trading company . 2. Q: Where is your factory located? How can I visit there? A: Our factory is located in Shijiazhuang City, the capital of Hebei Province.

It’s near the airport and train station. 3. Q: How does your factory do regarding quality control? A: Sure, we test our machine before shipping. Our factory has gained ISO9001:2008 authentication. Kindly contact us:

Send your inquiry to this supplier