1 / 6

High Efficiency Vibrator Bowl Feeder for Mining

Get Latest Price

Send Inquiry

| Model No. : | GZD series |

|---|---|

| Brand Name : | SHUNKY |

Shanghai Shunky Machinery Co., Ltd.

You might also like

Product description

Specifications Vibrator Bowl Feeder:

1. Large capacity:20-600 TPH

2. Small power: 7.5-45 KW

3. Low price: 6000-20000 USD

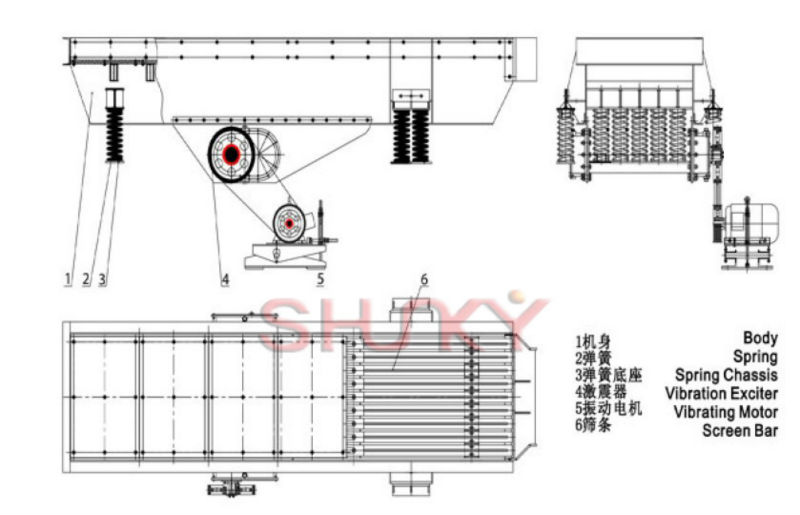

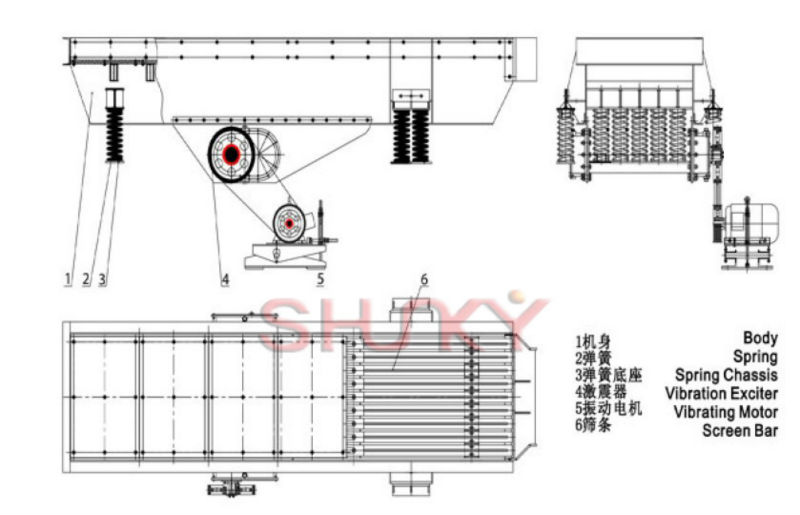

Product Description Vibrator Bowl Feeder Brief Introduction Vibrator Bowl Feeder , also known as vibrating feeding machine. The GZD series vibrating feeder is a new type and designed for transporting bulk materials before crushing and screening. Vibrating feeder use double eccentric shaft vibrator, ensure that the equipment can withstand the large impact of falling material. The massive, granular materials can be uniformed regularly and continuously from hopper to receiving device to avoid rushing phenomenon in the production process and to extend equipment using life. Structure The Vibrator Bowl Feeder is mainly consists of frame, spring, vibrator, motor and support, etc. Working principle GZD series Vibrator Bowl Feeder is make up of vibrating frame, vibrator, spring bearing, transmission device, etc. The vibrating power comes from vibrator, The vibrator is contains two fixed eccentric shafts with jogged gears, the motor transmits power through belt and drives one eccentric shaft, the other eccentric shaft moved through the gears, two eccentric shafts spin in the opposite way, which helps transfer materials from hopper to receiving device evenly and continuously.

Working principle GZD series Vibrator Bowl Feeder is make up of vibrating frame, vibrator, spring bearing, transmission device, etc. The vibrating power comes from vibrator, The vibrator is contains two fixed eccentric shafts with jogged gears, the motor transmits power through belt and drives one eccentric shaft, the other eccentric shaft moved through the gears, two eccentric shafts spin in the opposite way, which helps transfer materials from hopper to receiving device evenly and continuously.

Technical data

Pictures

Delivery Site

Delivery Site  Company Profile Shanghai Shunky Machinery Co., Ltd is a professional crushing and screening equipment manufacturer with R&D, production, marketing and service rolled into one. Since its foundation in 1996, Shunky has been devoted itself to the R&D and manufacture of mining crushing equipment, sand making equipment and industrial grinding mill, including jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher(sand making machine), mobile crushing plant, vibrating screen etc.

Company Profile Shanghai Shunky Machinery Co., Ltd is a professional crushing and screening equipment manufacturer with R&D, production, marketing and service rolled into one. Since its foundation in 1996, Shunky has been devoted itself to the R&D and manufacture of mining crushing equipment, sand making equipment and industrial grinding mill, including jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher(sand making machine), mobile crushing plant, vibrating screen etc.  Decades of experience in machinery R&D and manufacture, more than 100 square metres of production base, professional technology and a service team of nearly 1000 specialized staff provide Shanghai Shunky with infinite power to build its great foundation. Currently, Shanghai Shunky main products have passed the CE certification. In sales network, Shunky covers not only Hunan, Shanxi, Qinghai, Xinjiang, Guangxi and Yunnan province in China but also dozens of countries and regions like Russia, Mongolia, Vietnam, Sri Lanka, Saudi Arabia, Lebanon, Qatar, Malaysia, the Philippines, Nigeria, Congo, Ethiopia, Australia, Peru, Brazil with annual sales over 200 million RMB. Shunky agents developed in Saudi Arabia, Russia, Mongolia and Malaysia provide customers with convenient service. Workshops&Equipment

Decades of experience in machinery R&D and manufacture, more than 100 square metres of production base, professional technology and a service team of nearly 1000 specialized staff provide Shanghai Shunky with infinite power to build its great foundation. Currently, Shanghai Shunky main products have passed the CE certification. In sales network, Shunky covers not only Hunan, Shanxi, Qinghai, Xinjiang, Guangxi and Yunnan province in China but also dozens of countries and regions like Russia, Mongolia, Vietnam, Sri Lanka, Saudi Arabia, Lebanon, Qatar, Malaysia, the Philippines, Nigeria, Congo, Ethiopia, Australia, Peru, Brazil with annual sales over 200 million RMB. Shunky agents developed in Saudi Arabia, Russia, Mongolia and Malaysia provide customers with convenient service. Workshops&Equipment

Cooperation

Cooperation  Welcome customers all over the world come to inspect! Our products are exported to following countries:

Welcome customers all over the world come to inspect! Our products are exported to following countries:

Qualification&Honor

Qualification&Honor

Service Support Pre-sales service: (1)Select equipment model;

Service Support Pre-sales service: (1)Select equipment model;

(2)Design and manufacture products according to clients' specific requirement;

(3)Train technical personnel for clients; Service during the sale:

Service during the sale:

(1)Product inspection and acceptance.

(2) Associate clients to make program plan. After-sales service:

(1)Send the professional engineers to the customer’s site to guide to install and debug the equipment;

(2)Train the first-line operators on site;

(3) After the installation, we will leave 1-2 full-time staff and help customers observe the operating condition till their satisfaction. Please contact with us to get more details.

1. Large capacity:20-600 TPH

2. Small power: 7.5-45 KW

3. Low price: 6000-20000 USD

Product Description Vibrator Bowl Feeder Brief Introduction Vibrator Bowl Feeder , also known as vibrating feeding machine. The GZD series vibrating feeder is a new type and designed for transporting bulk materials before crushing and screening. Vibrating feeder use double eccentric shaft vibrator, ensure that the equipment can withstand the large impact of falling material. The massive, granular materials can be uniformed regularly and continuously from hopper to receiving device to avoid rushing phenomenon in the production process and to extend equipment using life. Structure The Vibrator Bowl Feeder is mainly consists of frame, spring, vibrator, motor and support, etc.

Working principle GZD series Vibrator Bowl Feeder is make up of vibrating frame, vibrator, spring bearing, transmission device, etc. The vibrating power comes from vibrator, The vibrator is contains two fixed eccentric shafts with jogged gears, the motor transmits power through belt and drives one eccentric shaft, the other eccentric shaft moved through the gears, two eccentric shafts spin in the opposite way, which helps transfer materials from hopper to receiving device evenly and continuously.

Working principle GZD series Vibrator Bowl Feeder is make up of vibrating frame, vibrator, spring bearing, transmission device, etc. The vibrating power comes from vibrator, The vibrator is contains two fixed eccentric shafts with jogged gears, the motor transmits power through belt and drives one eccentric shaft, the other eccentric shaft moved through the gears, two eccentric shafts spin in the opposite way, which helps transfer materials from hopper to receiving device evenly and continuously. Technical data

Model | Feed chute size (mm) | Max. feeding size(mm) | Handling capacity (t/h) | Power (kw) | Overall dimension (mm) | Weight (kg) |

GZD-960X3800 | 960X3800 | 500 | 120-210 | 11 | 3850X1950X1630 | 4200 |

GZD-1100X4200 | 1100X4200 | 650 | 180-400 | 15 | 4400X2050X1660 | 4800 |

GZD-1100X4900 | 1100X4900 | 650 | 250X480 | 15 | 5200X2050X1700 | 5300 |

GZD-1300X4900 | 1300X4900 | 800 | 300X550 | 22 | 5200X2350X1750 | 6700 |

GZD-1300X6000 | 1300X6000 | 800 | 400-800 | 30 | 6082X2580X2083 | 7800 |

Delivery Site

Delivery Site  Company Profile Shanghai Shunky Machinery Co., Ltd is a professional crushing and screening equipment manufacturer with R&D, production, marketing and service rolled into one. Since its foundation in 1996, Shunky has been devoted itself to the R&D and manufacture of mining crushing equipment, sand making equipment and industrial grinding mill, including jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher(sand making machine), mobile crushing plant, vibrating screen etc.

Company Profile Shanghai Shunky Machinery Co., Ltd is a professional crushing and screening equipment manufacturer with R&D, production, marketing and service rolled into one. Since its foundation in 1996, Shunky has been devoted itself to the R&D and manufacture of mining crushing equipment, sand making equipment and industrial grinding mill, including jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher(sand making machine), mobile crushing plant, vibrating screen etc.  Decades of experience in machinery R&D and manufacture, more than 100 square metres of production base, professional technology and a service team of nearly 1000 specialized staff provide Shanghai Shunky with infinite power to build its great foundation. Currently, Shanghai Shunky main products have passed the CE certification. In sales network, Shunky covers not only Hunan, Shanxi, Qinghai, Xinjiang, Guangxi and Yunnan province in China but also dozens of countries and regions like Russia, Mongolia, Vietnam, Sri Lanka, Saudi Arabia, Lebanon, Qatar, Malaysia, the Philippines, Nigeria, Congo, Ethiopia, Australia, Peru, Brazil with annual sales over 200 million RMB. Shunky agents developed in Saudi Arabia, Russia, Mongolia and Malaysia provide customers with convenient service. Workshops&Equipment

Decades of experience in machinery R&D and manufacture, more than 100 square metres of production base, professional technology and a service team of nearly 1000 specialized staff provide Shanghai Shunky with infinite power to build its great foundation. Currently, Shanghai Shunky main products have passed the CE certification. In sales network, Shunky covers not only Hunan, Shanxi, Qinghai, Xinjiang, Guangxi and Yunnan province in China but also dozens of countries and regions like Russia, Mongolia, Vietnam, Sri Lanka, Saudi Arabia, Lebanon, Qatar, Malaysia, the Philippines, Nigeria, Congo, Ethiopia, Australia, Peru, Brazil with annual sales over 200 million RMB. Shunky agents developed in Saudi Arabia, Russia, Mongolia and Malaysia provide customers with convenient service. Workshops&Equipment

Cooperation

Cooperation  Welcome customers all over the world come to inspect! Our products are exported to following countries:

Welcome customers all over the world come to inspect! Our products are exported to following countries:

Qualification&Honor

Qualification&Honor

Service Support Pre-sales service: (1)Select equipment model;

Service Support Pre-sales service: (1)Select equipment model;(2)Design and manufacture products according to clients' specific requirement;

(3)Train technical personnel for clients;

Service during the sale:

Service during the sale: (1)Product inspection and acceptance.

(2) Associate clients to make program plan. After-sales service:

(1)Send the professional engineers to the customer’s site to guide to install and debug the equipment;

(2)Train the first-line operators on site;

(3) After the installation, we will leave 1-2 full-time staff and help customers observe the operating condition till their satisfaction. Please contact with us to get more details.

Send your inquiry to this supplier

Send Inquiry