1 / 6

High Efficiency Limestone Quartz Marble Chemicals Mine Coal Granite Stone Jaw Crusher Machine Construction Crushing Machinery

| Model No. : | PE750*1060 JAW CRUSHER |

|---|---|

| Brand Name : | Shanai mini jaw crusher |

Product description

Jaw Stone Crusher Jaw crusher is a type of effective and energy conservation crushing machinery. Medium and large scale jaw crusher is main product of Shanai, and we have reached international level on designing and producing large scale crusher. Jaw crusher is main applied in all kinds of ore and big block material medium size crushing, material's hardness should be less than 320Mpa, coarse crushing and fine crushing are available. This series has a complete range of specifications, feeding size could be 125mm~750mm, it's the first choice of primary crushing. Jaw crusher could be widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industries.

Advantage of Jaw crusher

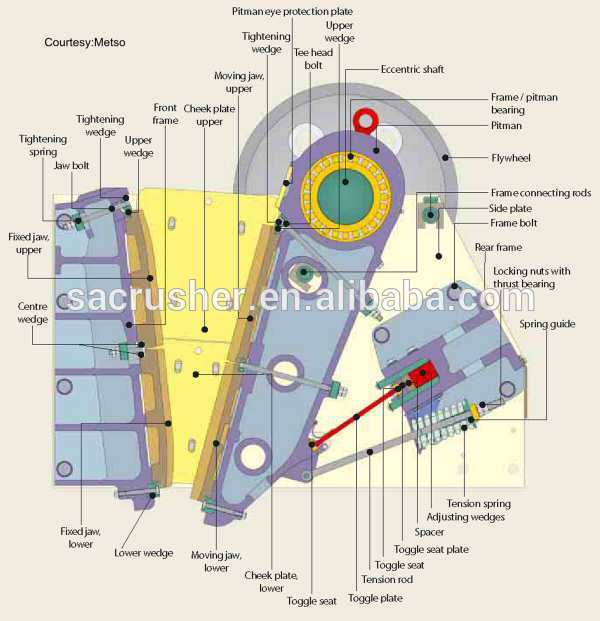

1.Compact Structure and Unique Design: Unique jaw head structure and perfect seal lengthen bearing’s service life.Unique flywheel design reduces the shock of machine to guarantee stable operation.

2.Adjustment Device of Discharge Port: Spacer type discharge port adjustment device is very reliable, wide range of adjusting, flexibility of the machine is increased. 3.Energy-Efficient & Long Service Life: Deep crushing cavity, no dead corner. Input size range and capacity are increased; big crushing radio, even final product, new oil-way design can match up with oil pump, easier and effective operation. 4.Mono-Block Cast & High Safety Factor: Adopting mono-block cast and and new assembly technology could make it match up with rack perfectly, radial strength is increased. Working Principle of Jaw Crusher: Motor drives eccentric shaft rotating by belt pulley, moving jaw is forced to move to or leave from fixed jaw, material will be squeezed, twisted and been grinding, material will be crushed to smaller size and final product will fall down and discharged from discharge port.

Technical parameters of jaw stone crusher

Technical parameters of jaw stone crusher Model | Feed Opening | Max. Feed Size | Capacity | Power | Discharge Opening | Weight (t) | Overall Dimension |

PE400×600 | 400×600 | 340 | 16-55 | 30 | 40-100 | 6.5 | 1565×1732×1586 |

PE500×750 | 500×750 | 425 | 32-80 | 55 | 50-120 | 10.3 | 1890×1916×1870 |

PE600×900 | 600×900 | 500 | 50-120 | 55-75 | 65-160 | 15.5 | 2305×1840×2298 |

PE750×1060 | 750×1060 | 630 | 100-180 | 110 | 80-140 | 28 | 2450×2472×2840 |

PE800×1060 | 800×1060 | 640 | 136-230 | 110 | 100-200 | 29 | 2500×2472×2840 |

PE870×1060 | 870×1060 | 660 | 190-336 | 110 | 200-260 | 30.5 | 2870×2430×2800 |

PE900×1200 | 900×1200 | 750 | 180-280 | 132 | 120-240 | 46.5 | 3435×2904×2990 |

PE1000×1200 | 1000×1200 | 850 | 200-300 | 132 | 220-340 | 47 | 3335×2904×2990 |

PE1200×1500 | 1200×1500 | 1000 | 300-500 | 200 | 150-300 | 79 | 4587×3342×3553 |

PE1500×1800 | 1500×1800 | 1200 | 500-800 | 280 | 220-350 | 122 | 5160×3660×4248 |

PEX-250×1000 | 250×1000 | 210 | 16-52 | 30-37 | 25-60 | 6.5 | 1530×1992×1380 |

PEX-250×1200 | 250×1200 | 210 | 20-60 | 37 | 25-60 | 7.7 | 1900×2192×1430 |

PEX-300×1300 | 300×1300 | 250 | 16-104 | 55 | 20-90 | 1.1 | 1750×2320×1400 |

PEX-350×1200 | 350×1200 | 300 | 70-140 | 75 | 70-140 | 11.43 | 2123×2250×1721 |

Why Choose us? 1. We are Manufacturer

Why Choose us? 1. We are Manufacturer a. We have complete production line for both spare parts and machineries, and our spare parts factory is one of the biggest in China. All products are made by ourselves, with competitive price, good quality and 7*24 after service plus technical support. b. We can provide OEM & ODM service for machineries and parts as per your request. Also, customize can be accepted.

2. Training & Service: a. We can provide pre-installtion scheme plan, process flow design as per your request. b. We can send technicians to the jobsite for installation guidance & adjustment, also we can train your operators if you need ( all of that is free). c. We keep stock for regular spare parts and machineries, which means the delivery and loading takes shorter time. 3. If you are new in this business, we can:

a. Help you to choose the right equipments and spare parts. b. Design complete production lines according to your demand. c. Assist spot or jobsite inspection and operator training. 4. We’d be glad to recommend suitable machine for you with best price. So please try to give us more information about your demand, such as: a.The type and size of raw material. b.The required size of final product(mm). c.The production capacity you want. Application APPLICABLE MATERIALS:

Chemicals, Mine, Coal, Granite, Rock, Stone, Marble, Griotte, Calcium Carbonate, Domolite, Limestone, Limerock, Calcareous Stone, Conquina, Siliceous Limestone, Chromite Ore, Mineral, Cement, Concrete, Compound, Cobblestone, Iron Ore, Ironstone, Iron-mineral soils, Copper Ore, Azurite, Copper Sulphide Ore, Quartz Stone, Quartzite, Keli Stone, Silestone, Coal, Gold Ore, Basalt, Whinstone, Shaly, Shale, Mudstone, Nonferrous Metals Ore, etc.

RANGE OF APPLICATIONS:

and Making Plant, Construction Waste Recycling, Household Waste Processing, Labratory, Quarry, Road Constructions, Building Construstion, Cement Plant, Building, Highway, Chemical, Metallurge, Mining Industries, Coal Mine, Gold Mine, Benification, Mineral Separation, Stone Production, Brick Making, Ore Dressing, etc.

FAQ Q:Instalation

A:At the client’s request, Shanai can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. Travel and accommodation costs, plus US$50 per day per man to be met by the client. Q:Payment A:30% by TT as deposit on signing the contract, 70% by as final payment of balance after the client’s satisfactory inspection of the equipment prior to the goods leaving the Shanai factory for stone crusher machine manufacturer

Q: What about Warranty? what will we do if the machine is broken down

A: The warranty period for all of Shanai’s structural and mechanical equipment is one year. The warranty period for all electric motors is half one year. Wear parts are not covered by warranty unless the component part is found to be flawed. Q: What should we need to do for if we want to get a best quotation

A: Hi, if you want us recommend a suitable type for you ,please let us know as follows:

1).the capacity (tons per hour ) 2).output size 3).stone type

Q: What could you help me to do for the business ?

A: Many thanks for your trust , we can provide you with proposal chart for complete production lines ,spot inspection and operator traning according to your demands and the conditions of applied spot , we can help you choose the right equipments , drilling rig ,loader ,trucks ,excavators and so on . Q:What's your After sales Service

A:All equipment manufactured by Shanai is of the highest standard and very rarely have our clients experienced any mechanical problems. Should any problems occur, our team of Engineers and Technicians will respond within12 hours of notice by the client for stone crusher machine manufacturer Q:Delivery time

A:Standard delivery time for stationary crusher plant is 30 days from receipt of deposit.the mobile crusher plant is 45 days,

Send your inquiry to this supplier