1 / 3

High Capacity Ducting PE Pipe Making Machine

| Brand Name : | LANGBO |

|---|---|

| place of origin : | China |

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

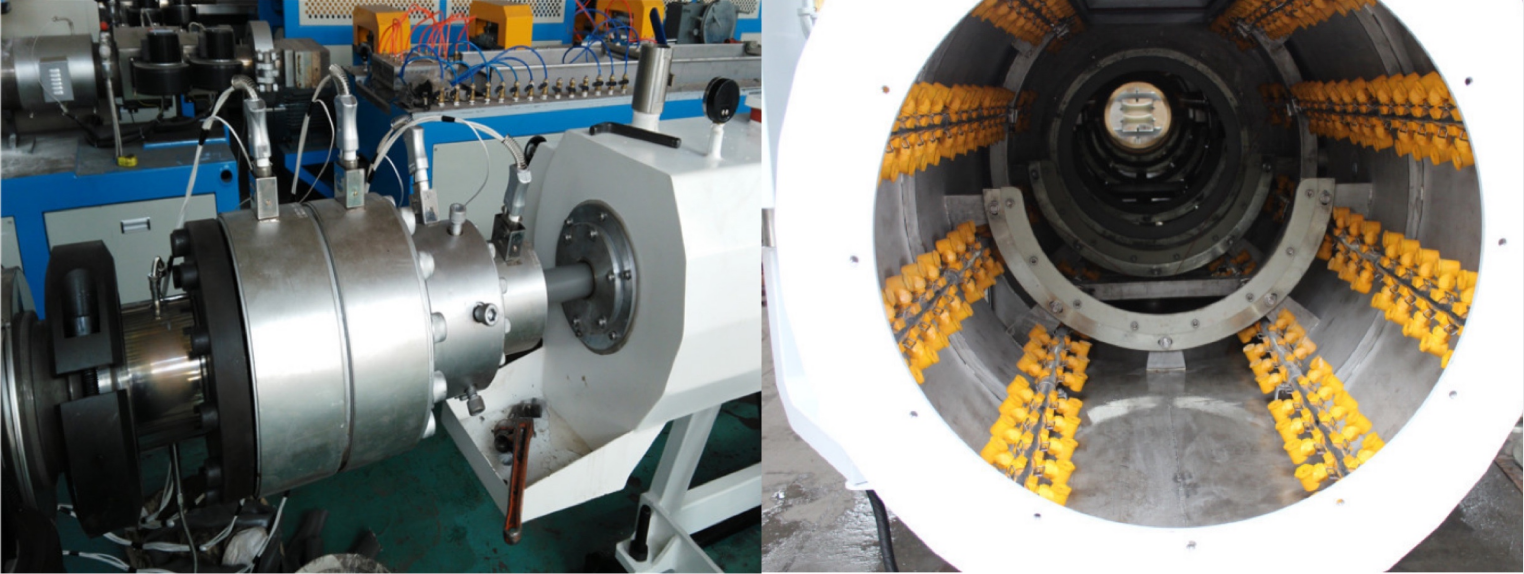

High Capacity Plastic Pipe Extrusion Line

HIGHLIGHT OF PRODUCTION LINE BY LANGBO MACHINERY:

• A great wealth of experience,

• A consistent focus on the highest quality

• A complete twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

• A highly motivated team

• Sophisticated process technology

• Customized solutions

PROCESS AND COMPONENTS OF THE FULL PRODUCTION LINE:

The first step of pipe production is the preparation of raw material. Customers can mix the PVC powder with other additives by themself. The mixture will be fed into extruder. The material will be plasticized in the extruder and then be extruded into the mould. The material is shaped by mould and goes out with the pipe looking. The pipe extruded from the mould is hot and soft. The pipe with unstable shape will be calibrated and cooled by vacuum sleeve in the vacuum calibration tank. And then the pipe goes into the cooling tank for a further cooling. Haul off unit stands next to the cooling tank and take the pipe away from the extruder. According to the defined length, the pipe will be cut and then packed for transport.

In a word, the whole process can be concluded into a more concise line as following:

A. Single screw extruder B. PPR/PE/PP pipe extrusion mould C. Vacuum shaping platform

D. Haul off machine E. Cutting machin F. Stacker

AFTER-SALE SERVICE&TECHNOLOGY SUPPORT:

• To install products and test products freely for customers.

• To provide the formulas and technologies of relevant products and the information of chemical

materials manufactures

• To direct technology aspect of relevant use according to customers’ requirements

• To provide technical training for clients’ employees.

• To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier