1 / 1

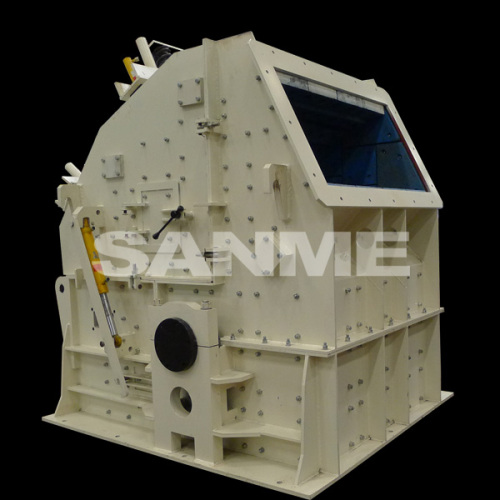

HC Series Impact Mill Crusher For Gravel Aggregate

Get Latest Price

Send Inquiry

| Model No. : | HC impact mill crusher |

|---|---|

| Brand Name : | SANME impact mill crusher |

Shanghai Sanme Mining Machinery Co., Ltd.

You might also like

Product description

Specifications 1, impact mill crusher

2,50-1200TPH

3,ISO/CE, German Tech

4, After-sale service available

SHANGHAI SANME MINING MACHINERY CO., LTD., leading crushing and screening equipment manufacturers in China, a joint venture with HAZEMAG, Germany.

HC Series impact mill crusher HC Series impact mill crusher are built on advanced technology with a combination of domestic applications. The overall structure is simple, practical and reasonable.

HC Series impact mill crusher HC Series impact mill crusher are built on advanced technology with a combination of domestic applications. The overall structure is simple, practical and reasonable.  Features and technology advantages of impact mill crusher: 1. High-quality plates and wear parts to reduce abrade and improve the production efficiency of various conditions; advanced processing technology is the basis of equipment performance. 2. Strong product commonality can reduce cost. Two-cavity small stone crusher machine can becomes three-cavity machine by adding grinding racks, and no need to change other parts. 3. Heavy type rotor, finite element endurance analysis, optimized design, reasonable structure and enhancing moment of inertia lead to bigger crushing ratio and better abrasion resistance. 4. Static and dynamic balancing test for the welding rotor should be done before assembling. To make sure the rotor has a smoothly running and long working life. 5.Main shaft is finished by quality forging, adopts keyless design and world advanced cover tightening connection to ensure the reliable working and make the maintenance easier. 6.Unique locking device for hammers makes the tightening moment of force more safe and bigger. And the replacement of hammers can be more simple and convenient.

Features and technology advantages of impact mill crusher: 1. High-quality plates and wear parts to reduce abrade and improve the production efficiency of various conditions; advanced processing technology is the basis of equipment performance. 2. Strong product commonality can reduce cost. Two-cavity small stone crusher machine can becomes three-cavity machine by adding grinding racks, and no need to change other parts. 3. Heavy type rotor, finite element endurance analysis, optimized design, reasonable structure and enhancing moment of inertia lead to bigger crushing ratio and better abrasion resistance. 4. Static and dynamic balancing test for the welding rotor should be done before assembling. To make sure the rotor has a smoothly running and long working life. 5.Main shaft is finished by quality forging, adopts keyless design and world advanced cover tightening connection to ensure the reliable working and make the maintenance easier. 6.Unique locking device for hammers makes the tightening moment of force more safe and bigger. And the replacement of hammers can be more simple and convenient.  7.Standard design for liners increase the interchangeability, decrease the repertory and variety of liners. 8.Simple but practical locking device lock the shell 1 and shell 2 together. This device has a easy operation and saves locking time. 9.Unique hydraulic device design is convenient for opening the fame racks to replace wear parts and adjust the discharge size. 10.Simple structure for impact racks and grinding racks. Easy operation, long working life, convenient maintenance and low cost.

7.Standard design for liners increase the interchangeability, decrease the repertory and variety of liners. 8.Simple but practical locking device lock the shell 1 and shell 2 together. This device has a easy operation and saves locking time. 9.Unique hydraulic device design is convenient for opening the fame racks to replace wear parts and adjust the discharge size. 10.Simple structure for impact racks and grinding racks. Easy operation, long working life, convenient maintenance and low cost.  Optimized crushing chamber, higher capacity for impact mill crusher The crushing chamber of HC series impact mill crusher is optimized, which obtains extra capacity, improves crushing reduction and lower your capital costs. Bigger feed opening design, bigger material crushed for impact mill crusher By optimization, HC series impact mill crusher use enlarged feed opening design, which can crush bigger material. When crushing medium hard material eg. Limestone, they can replace jaw crusher. Especially in crushing oversized concrete in the construction waste, they have more advantges. Adding grinding cavity design (Optional), wide application for impact mill crusher With the design of grinding cavity, HC series impact mill crusher achieves bigger crushing ratio, lower discharge opening and excellent product shape. More choice for customers makes more application. Heavy rotor design and unique blow bar fixing system provide reliability for impact mill crusher HC series impact mill crusher adopt heavy rotor design, which not only improves reliability, but also increases moment of inertia of rotor and capacity. The fixing of blow bar is improved to make the exchange easy and fixing reliable. Reliable overload and tramp iron protection device for impact mill crusher For the protection of the rotor body and blow bars, the HC series impact mill crusher optimize overload and tramp iron protection device. The impact aprons retract under excessive load. As soon as the load value returns to normal, the impact aprons resumes its pre-set position, and operation continues without interruption. Easy to maintain, high reliability and safety for impact mill crusher The hydraulic power unit is used by HC series impact mill crusher for easy adjustment of setting. It is convenient for checking, maintaining and changing wear parts.

Optimized crushing chamber, higher capacity for impact mill crusher The crushing chamber of HC series impact mill crusher is optimized, which obtains extra capacity, improves crushing reduction and lower your capital costs. Bigger feed opening design, bigger material crushed for impact mill crusher By optimization, HC series impact mill crusher use enlarged feed opening design, which can crush bigger material. When crushing medium hard material eg. Limestone, they can replace jaw crusher. Especially in crushing oversized concrete in the construction waste, they have more advantges. Adding grinding cavity design (Optional), wide application for impact mill crusher With the design of grinding cavity, HC series impact mill crusher achieves bigger crushing ratio, lower discharge opening and excellent product shape. More choice for customers makes more application. Heavy rotor design and unique blow bar fixing system provide reliability for impact mill crusher HC series impact mill crusher adopt heavy rotor design, which not only improves reliability, but also increases moment of inertia of rotor and capacity. The fixing of blow bar is improved to make the exchange easy and fixing reliable. Reliable overload and tramp iron protection device for impact mill crusher For the protection of the rotor body and blow bars, the HC series impact mill crusher optimize overload and tramp iron protection device. The impact aprons retract under excessive load. As soon as the load value returns to normal, the impact aprons resumes its pre-set position, and operation continues without interruption. Easy to maintain, high reliability and safety for impact mill crusher The hydraulic power unit is used by HC series impact mill crusher for easy adjustment of setting. It is convenient for checking, maintaining and changing wear parts.

Gradation Curves impact mill crusher  ♥ Welcome to SANME showroom! ♥ If you want to know more detailed information about our products, please feel free to contact us at any time!

♥ Welcome to SANME showroom! ♥ If you want to know more detailed information about our products, please feel free to contact us at any time!

2,50-1200TPH

3,ISO/CE, German Tech

4, After-sale service available

SHANGHAI SANME MINING MACHINERY CO., LTD., leading crushing and screening equipment manufacturers in China, a joint venture with HAZEMAG, Germany.

HC Series impact mill crusher HC Series impact mill crusher are built on advanced technology with a combination of domestic applications. The overall structure is simple, practical and reasonable.

HC Series impact mill crusher HC Series impact mill crusher are built on advanced technology with a combination of domestic applications. The overall structure is simple, practical and reasonable.  Features and technology advantages of impact mill crusher: 1. High-quality plates and wear parts to reduce abrade and improve the production efficiency of various conditions; advanced processing technology is the basis of equipment performance. 2. Strong product commonality can reduce cost. Two-cavity small stone crusher machine can becomes three-cavity machine by adding grinding racks, and no need to change other parts. 3. Heavy type rotor, finite element endurance analysis, optimized design, reasonable structure and enhancing moment of inertia lead to bigger crushing ratio and better abrasion resistance. 4. Static and dynamic balancing test for the welding rotor should be done before assembling. To make sure the rotor has a smoothly running and long working life. 5.Main shaft is finished by quality forging, adopts keyless design and world advanced cover tightening connection to ensure the reliable working and make the maintenance easier. 6.Unique locking device for hammers makes the tightening moment of force more safe and bigger. And the replacement of hammers can be more simple and convenient.

Features and technology advantages of impact mill crusher: 1. High-quality plates and wear parts to reduce abrade and improve the production efficiency of various conditions; advanced processing technology is the basis of equipment performance. 2. Strong product commonality can reduce cost. Two-cavity small stone crusher machine can becomes three-cavity machine by adding grinding racks, and no need to change other parts. 3. Heavy type rotor, finite element endurance analysis, optimized design, reasonable structure and enhancing moment of inertia lead to bigger crushing ratio and better abrasion resistance. 4. Static and dynamic balancing test for the welding rotor should be done before assembling. To make sure the rotor has a smoothly running and long working life. 5.Main shaft is finished by quality forging, adopts keyless design and world advanced cover tightening connection to ensure the reliable working and make the maintenance easier. 6.Unique locking device for hammers makes the tightening moment of force more safe and bigger. And the replacement of hammers can be more simple and convenient.  7.Standard design for liners increase the interchangeability, decrease the repertory and variety of liners. 8.Simple but practical locking device lock the shell 1 and shell 2 together. This device has a easy operation and saves locking time. 9.Unique hydraulic device design is convenient for opening the fame racks to replace wear parts and adjust the discharge size. 10.Simple structure for impact racks and grinding racks. Easy operation, long working life, convenient maintenance and low cost.

7.Standard design for liners increase the interchangeability, decrease the repertory and variety of liners. 8.Simple but practical locking device lock the shell 1 and shell 2 together. This device has a easy operation and saves locking time. 9.Unique hydraulic device design is convenient for opening the fame racks to replace wear parts and adjust the discharge size. 10.Simple structure for impact racks and grinding racks. Easy operation, long working life, convenient maintenance and low cost.  Optimized crushing chamber, higher capacity for impact mill crusher The crushing chamber of HC series impact mill crusher is optimized, which obtains extra capacity, improves crushing reduction and lower your capital costs. Bigger feed opening design, bigger material crushed for impact mill crusher By optimization, HC series impact mill crusher use enlarged feed opening design, which can crush bigger material. When crushing medium hard material eg. Limestone, they can replace jaw crusher. Especially in crushing oversized concrete in the construction waste, they have more advantges. Adding grinding cavity design (Optional), wide application for impact mill crusher With the design of grinding cavity, HC series impact mill crusher achieves bigger crushing ratio, lower discharge opening and excellent product shape. More choice for customers makes more application. Heavy rotor design and unique blow bar fixing system provide reliability for impact mill crusher HC series impact mill crusher adopt heavy rotor design, which not only improves reliability, but also increases moment of inertia of rotor and capacity. The fixing of blow bar is improved to make the exchange easy and fixing reliable. Reliable overload and tramp iron protection device for impact mill crusher For the protection of the rotor body and blow bars, the HC series impact mill crusher optimize overload and tramp iron protection device. The impact aprons retract under excessive load. As soon as the load value returns to normal, the impact aprons resumes its pre-set position, and operation continues without interruption. Easy to maintain, high reliability and safety for impact mill crusher The hydraulic power unit is used by HC series impact mill crusher for easy adjustment of setting. It is convenient for checking, maintaining and changing wear parts.

Optimized crushing chamber, higher capacity for impact mill crusher The crushing chamber of HC series impact mill crusher is optimized, which obtains extra capacity, improves crushing reduction and lower your capital costs. Bigger feed opening design, bigger material crushed for impact mill crusher By optimization, HC series impact mill crusher use enlarged feed opening design, which can crush bigger material. When crushing medium hard material eg. Limestone, they can replace jaw crusher. Especially in crushing oversized concrete in the construction waste, they have more advantges. Adding grinding cavity design (Optional), wide application for impact mill crusher With the design of grinding cavity, HC series impact mill crusher achieves bigger crushing ratio, lower discharge opening and excellent product shape. More choice for customers makes more application. Heavy rotor design and unique blow bar fixing system provide reliability for impact mill crusher HC series impact mill crusher adopt heavy rotor design, which not only improves reliability, but also increases moment of inertia of rotor and capacity. The fixing of blow bar is improved to make the exchange easy and fixing reliable. Reliable overload and tramp iron protection device for impact mill crusher For the protection of the rotor body and blow bars, the HC series impact mill crusher optimize overload and tramp iron protection device. The impact aprons retract under excessive load. As soon as the load value returns to normal, the impact aprons resumes its pre-set position, and operation continues without interruption. Easy to maintain, high reliability and safety for impact mill crusher The hydraulic power unit is used by HC series impact mill crusher for easy adjustment of setting. It is convenient for checking, maintaining and changing wear parts. | Model | Feed Opening | Max Feed Size | Capacity(t/hr) | Power | Overall Dimensions (LXWXH) | Weight(Excluding Motor)(t) |

| HC128(A) | 780×630 | 300 | 50-130 | 55-90 | 2890(3058)×1748×2932 | 10.8 |

| HC139(A) | 1100×630 | 400 | 130-210 | 90-132 | 2890(3058)×2048×2932 | 13.6 |

| HC239(A) | 1100×740 | 500 | 180-280 | 110-160 | 2926(3095)×2048×2864 | 14.7 |

| HC255(A) | 1450×760 | 500 | 200-300 | 160-200 | 2893(3095)×2398×2970 | 17.4 |

| HC359(A) | 1550x1070 | 700 | 220-330 | 200-250 | 3700x3025x3240 | 25.7 |

| HC459(A) | 1550x1130 | 750 | 300-460 | 250-315 | 3750(3754)x3022x3330 | 27.1 |

| HC579(A) | 2050×830 | 800 | 320-490 | 400-440 | 3582×3561×3266 | 36.3 |

| HC679(A) | 2050x1230 | 1100 | 480-750 | 400-440 | 3900x3600x3500 | 50.5 |

| HC779(A) | 2050x1670 | 1500 | 500-850 | 630 | 4770x4338x4849 | 78.9 |

| HC887(A) | 2540x1845 | 1600 | 800-1200 | 1000 | 5355x5399x5454 | 111.5 |

♥ Welcome to SANME showroom! ♥ If you want to know more detailed information about our products, please feel free to contact us at any time!

♥ Welcome to SANME showroom! ♥ If you want to know more detailed information about our products, please feel free to contact us at any time! Send your inquiry to this supplier

Send Inquiry