1 / 1

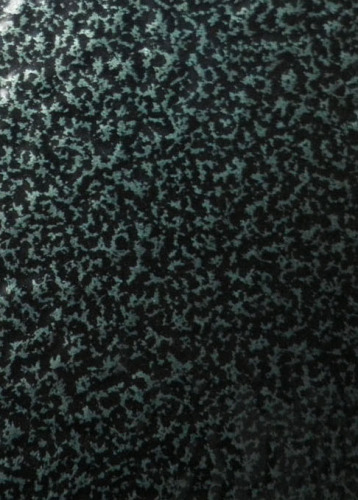

Green on Black Wrinkle Metallic Powder Coating (EP56012R)

Get Latest Price

Send Inquiry

| Model No. : | EP56012R |

|---|

Ningbo Zhenye Trading Co., Ltd.

You might also like

Product description

Green on Black ground Art-type Wrinkle texture finish Metallic Powder Coating

Product Brief

1. Maintained decorative and protective properties

2. Improved color and thermal stability

3. Excellent corrosion resistance capability

4. Epoxy Polyester powder coating

5. Metallic powder coating

6. High quality and competitive price

7. Spray by electrostatic spray gun

8. For indoor use

Main Composition

It mainly made of Epoxy resin and Polyester resin and curing agent, leveling agent, pigment, filler and other addictives. It has super physical and chemical resistance properties. It can be used in spraying those metal products that have special requirement of corrosion resistance, electrical insulating property. Directly using for outdoor is not to be suggested.

Physical Property

1. Curing condition:

180° C/20min

190° C/15min

200° C/10min

2. Impact resistance: ASTM D2794 ≥ 50 cm*kg

3. Adhesion (cross-cut): ASTM D3359 ≤ Gt0

4. Pencil hardness: ASTM D3363 1H-2H

5. Flexibility: ASTM D522 ≤ 1/8"

6. Cupping test: GB/T 9753 6mm

7. Specific gravity: 1.2-1.8g/cm3 (varied with different color and gloss)

8. Particle size: Average 10~38um, proportion 10~84um > 90%, it can be adjusted if special requirement is put forward to us in advance.

Chemical Property

Neutral salt spray test: ASTM B117 ≥ 500hours

Humidity resistance: GB/T1740 >1, 000hours

Soaked in distilled water: BS3900-F7≥ 240hours

Chemical resistance: Excellent (testing at room temperature use general acid and oil)

Outdoor persistence: Exposure outdoor will change the color, after 6-12months exposure outdoor, there will be minor chalking

Pre-treatment

All metal substrate is required to be degreasing, ferrous metals use zinc or iron phosphates, aluminum recommend chromium treatment to improve the corrosion resistance. Generally substrate need to meet the neutral phosphate 48 hours, phosphate coating no abnormal. The overall quality of the coating system is largely dependent on the type and quality of the pre-treatment. The recommended types of pre-treatment for the most frequently used substrates are:

Aluminum/Chromate conversion

Steel/Zinc phosphate

Zinc coated steel/Zinc phosphate or chromate conversion

Coating Method

Electrostatic spray gun

Frictional gun

Electrostatic fluidized bed

Fluidized bed

Average Coating Rate

Wrinkle texture surface:

5-7 KG, film thickness is about 80-120μ M

Package

We usually use a very thick poly bag then with an export double corrugated carton: 25kg per poly bag then in a Xinming's export carton.

Storage and Shipment

The product must be stored in ventilated, dry and clean room with temperature below 30oC, keep it away from fire, heat, and direct sunlight. Outdoor stacking is prohibited. Avoid rains and exposure to sunshine during shipment. The period of validity is 6 month under above condition. Expired products can not be used unless re-testing result meets the utilization standards.

Product Brief

1. Maintained decorative and protective properties

2. Improved color and thermal stability

3. Excellent corrosion resistance capability

4. Epoxy Polyester powder coating

5. Metallic powder coating

6. High quality and competitive price

7. Spray by electrostatic spray gun

8. For indoor use

Main Composition

It mainly made of Epoxy resin and Polyester resin and curing agent, leveling agent, pigment, filler and other addictives. It has super physical and chemical resistance properties. It can be used in spraying those metal products that have special requirement of corrosion resistance, electrical insulating property. Directly using for outdoor is not to be suggested.

Physical Property

1. Curing condition:

180° C/20min

190° C/15min

200° C/10min

2. Impact resistance: ASTM D2794 ≥ 50 cm*kg

3. Adhesion (cross-cut): ASTM D3359 ≤ Gt0

4. Pencil hardness: ASTM D3363 1H-2H

5. Flexibility: ASTM D522 ≤ 1/8"

6. Cupping test: GB/T 9753 6mm

7. Specific gravity: 1.2-1.8g/cm3 (varied with different color and gloss)

8. Particle size: Average 10~38um, proportion 10~84um > 90%, it can be adjusted if special requirement is put forward to us in advance.

Chemical Property

Neutral salt spray test: ASTM B117 ≥ 500hours

Humidity resistance: GB/T1740 >1, 000hours

Soaked in distilled water: BS3900-F7≥ 240hours

Chemical resistance: Excellent (testing at room temperature use general acid and oil)

Outdoor persistence: Exposure outdoor will change the color, after 6-12months exposure outdoor, there will be minor chalking

Pre-treatment

All metal substrate is required to be degreasing, ferrous metals use zinc or iron phosphates, aluminum recommend chromium treatment to improve the corrosion resistance. Generally substrate need to meet the neutral phosphate 48 hours, phosphate coating no abnormal. The overall quality of the coating system is largely dependent on the type and quality of the pre-treatment. The recommended types of pre-treatment for the most frequently used substrates are:

Aluminum/Chromate conversion

Steel/Zinc phosphate

Zinc coated steel/Zinc phosphate or chromate conversion

Coating Method

Electrostatic spray gun

Frictional gun

Electrostatic fluidized bed

Fluidized bed

Average Coating Rate

Wrinkle texture surface:

5-7 KG, film thickness is about 80-120μ M

Package

We usually use a very thick poly bag then with an export double corrugated carton: 25kg per poly bag then in a Xinming's export carton.

Storage and Shipment

The product must be stored in ventilated, dry and clean room with temperature below 30oC, keep it away from fire, heat, and direct sunlight. Outdoor stacking is prohibited. Avoid rains and exposure to sunshine during shipment. The period of validity is 6 month under above condition. Expired products can not be used unless re-testing result meets the utilization standards.

Send your inquiry to this supplier

Send Inquiry