1 / 3

good solvent release Polyamide Resin general co-solvent for printing ink

| Model No. : | HY-108 |

|---|---|

| Brand Name : | HongTai |

Product description

| Item | Unit | Index | Test method |

| Acid Value | mgKOH/g | ≤5 | Titrimetry |

| Amine value | mgKOH/g | ≤5 | Titrimetry |

| Softening Point | ℃ | 110±5 | Ring-ball |

| Viscosity | mPa·s/25℃ | 100-180 | Rotary viscosimetry |

Mixing proportion: | |||

| Color | Size | ≤7 | Fe-Co colorimetry |

| Freezing point | ℃ | ≤7 | Freezing point instrument |

THE ADVANTAGES OF OUR FACTORY |

|

|

|

Advantages of Polyamide Resin | |

| 1. Good dissolubility of Polyamide Resin | |

| |

| 33g polyamide resin totally dissolved in 50ml solvent after 25 mins. | |

| Our polyamide resin is also characterized by good solubility. Please view the picture of dissolubility test: |

| 2. Excellent freezing resistance of Polyamide Resin | |

| |

| The polyamide resin solution recover to liquid at -1.9℃. | |

| Our polyamide resin is characterized by excellent resistance and high transparency , it can be well suitable for using in winter and the countries or areas with very low temperature. Kindly view the above picture of the freezing resistance test: if you meet any problem to play the left side video, please click here to download & play this video. |

| step 1. the polyamide resins are totally dissolved at 26 degree celsius, the test begins. (P.S.: Mixing proportion is 40% resin+60% solvent (Xylene:IPA:Ethanol=4:3:3) ) step 2. the liquid is still flowing at -6 degree celsius. step 3. the liquid becomes to get gelling at -7.6 degree celsius, but the transparency of the liquid is quite good. step 4. the gelling liquid was heated back to 26 degree celsius, the transparency is still excellent. Conclusion: 1. Our polyamide resin has a excellent resistance, if not, the resin solution will be easy to gel when the weather is cold. 2. Even if the resin solution gels, it will be still workable of the solution after heating and deflocculation. 3. Our polyamide resin has a high transparency, it ensures the pure colors of printing inks. |

PRODUCT QUALITY, PRODUCTION MANAGEMENT CERTIFICATION SYSTEM |

Based on its high quality and good reputation, we passed many authentication, such as REACH PRE-REGISTRATION, ISO9001:2008, ISO14001; OHSAS18001... Besides, the quality is also strictly controlled by the issuing of the certificate of analysis (COA). |

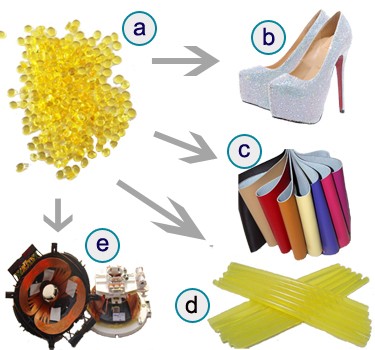

APPLICATIONS |

|

PACKING |

|

| Steady-- | Steady products and clients group thanks to 20+ years’ production experience, advanced equipments and mature test methods. |

| Safe-- | Standardized production process, fully-automatic and scientific operation guarantee production safety. |

| Environment-friendly-- | The first enterprise achieved cleaner production built sustainable green chemicals. |

| Customizable-- | Recommending proper products to customers based on the lastest market dynamics. |

| High-efficiency-- | Energy saving and consumption reducing, sincerely reward customers by high yield rate. |

| Considerate-- | Respond customers timely, sound after-sales service system. |

| Striving for perfection-- | A 20+ years’ striving for perfection team makes us at top rank. |

FAQ |

| Q: What is your test instrument for viscosity? A: NDJ-79 made in China. The viscosity tested by NDJ-79 is smaller than tested by BROOKFIELD made in America under the same conditions. Q: How long does the polyamide resins totally dissolve in the solvent? Q: Which one dried more quickly among co-solvent and alcohol-soluble polyamide resin? Q: What is the formula weight? Q: Can you produce according to Air or Sunmide standard? For more detail information, please click to send mail to us freely. |

Other products you may be interested in | |

| Anqing Hongyu Chemical Co., Ltd. was founded in 1998. Since establishment, we mainly engaged in research and development of dimer acid, also polyamide resin, polyamide hot melt adhesive. We have international advanced molecular distillation equipments, a production capacity of 5,000 MT per month, a workshop of 64,000 square maters. With continuous innovation, we are becoming a global enterprise gradually. | |

|  |

| a. dimer acid (our product) for b. polyamide resin c. polyamide hot melt adhesive d. modified epoxy resin e. lubricating oil f. cutting fluid/ epoxy curing agent/ epoxy adhesive g. spice slow releasing agent | a. polyamide hot melt adhesive (our product) for b. shoes making c. leather adhering d. glue stick making e. deflection coil adhering |

|

Send your inquiry to this supplier