1 / 1

GIGA LX Shanghai Highest Tech Hot Sale automatic carton box machine

Get Latest Price

Send Inquiry

| Model No. : | LX307/8N |

|---|---|

| Brand Name : | GIGA LX |

Liu Xiang General Equipments (Shanghai) Co., Ltd.

You might also like

Product description

Specifications automatic carton box machine

2.Memory 9999 orders

3.CNC adjusting system for die cutter

4.Flexo printing

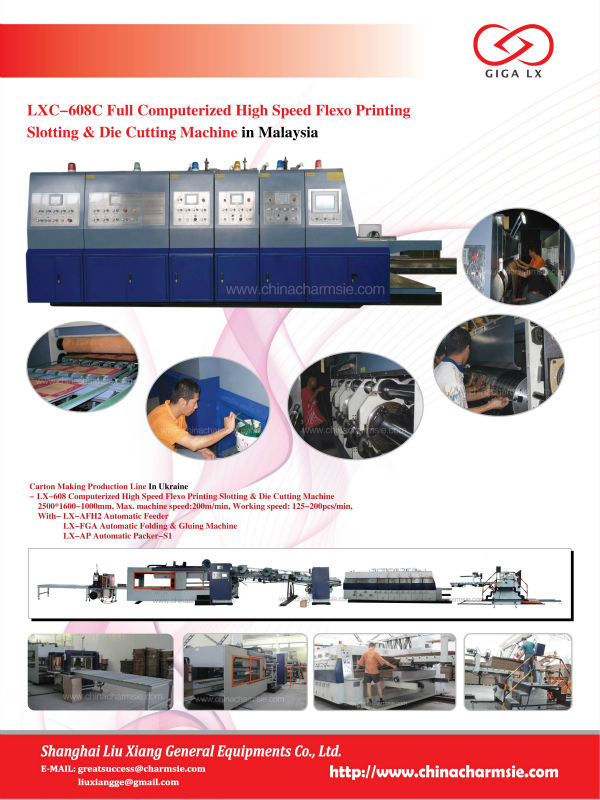

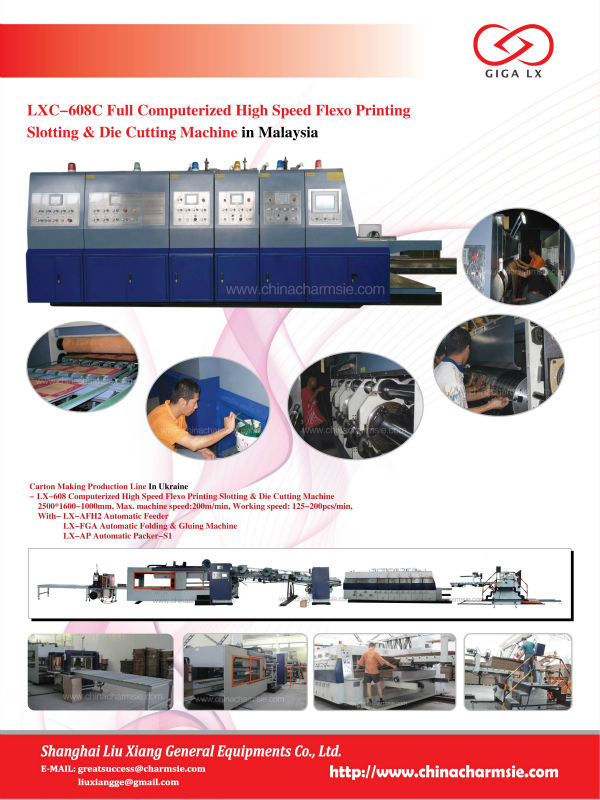

LX308N Automatic Flexo Printing Slotting and Die Cutting Machine automatic carton box machine Main functions: Remote after service could be realized; Touch screen and electric control dual system lx308 All transmission gears are made of high quality alloy steel (20CrMnTi) grinded under high temperature with hardness HRC58-62 CAPT-LOCKS union link to reduce the connect interval and keep long lasting overprint precision Functions of intelligent zero returning and memory reset 9999 order memory The transmission system adopts two oil pumps circulating lubrication With new NC Adjusting System for die cutter ; Slotter with Intelligent photoelectric lx308n. E flute type cardboard could be used for printing carton; Suitable for small and middl-big size carton and many order change Better machine better carton, so as to Better business. Pizza box making machine price and corrugated box making line machine price are best and high quality. We provide loan to below business situation

1. The value of order over RMB 1 million (including 1 million).

2. Only for box machine LX308N; LX608CN; LX707N or corrugated machine production line include LXC-180NN, LXC-220H1.8N models.

3. We accept O/A (Open account), it based on the credit level of buyer's bank credit report. lx308n

4. The details please consult with our sales department. Feeding Unit Servo control Lead edge feeder--patent #ZL2005 2 0045628.x (Back-pushing suck blower feeding system is option); Servo motor-quick react, lx308precision positioning, system stability and durability. Electrical camshaft supersedes mechanical style; Synchronous belt un-interval links feeding shaft with servo motor shaft, to improve feeding precision alignment; Half-wheel, quick replacing structure, to keep consistency of feeding position, and to avoid uneven wearing on the surface of feeding wheel; Pressure-free stretching feeding mechanism is the option; lx208n Printing Unit Box machine forme roller and pressure roller are made of high quality steel, with grinded and chrome plated surface, Dynamic and static balancing make steadily running, Hanging forme, make installation easy and quick, Forme changing both foot switch, and/or electric control (forward / backward run), Anilox roller auto lifting device synchronous working with paper feeding system (In feeding, anilox roller pressed whereas in stop, it released)

Servo motor-quick react, lx308precision positioning, system stability and durability. Electrical camshaft supersedes mechanical style; Synchronous belt un-interval links feeding shaft with servo motor shaft, to improve feeding precision alignment; Half-wheel, quick replacing structure, to keep consistency of feeding position, and to avoid uneven wearing on the surface of feeding wheel; Pressure-free stretching feeding mechanism is the option; lx208n Printing Unit Box machine forme roller and pressure roller are made of high quality steel, with grinded and chrome plated surface, Dynamic and static balancing make steadily running, Hanging forme, make installation easy and quick, Forme changing both foot switch, and/or electric control (forward / backward run), Anilox roller auto lifting device synchronous working with paper feeding system (In feeding, anilox roller pressed whereas in stop, it released)

Planetary gear phasing structure Printing phase automatic 360 degree adjust by PLC, touch screen and motorized digital control. Forme roller intelligent zero returning, short cut resetting under dynamic and static condition Motorized adjusts digital display the transversal position of the forme roller, up to 20 mm Slotting Machine Unit Pre-scoring wheel: Pre-scored paperboard will not crush Upper scoring wheel coated by polyurethane to avoid possible crush on the paperboard Transverse movement of scoring wheel, doctor wheel and slotting head controlled by motorized button control, lx308easy and quick 7 mm thick slotting knives are made of alloy tool steel by heat treatment and finely ground, sharpened endurable teeth Aluminium hand hole punch device. Die Cutting Unit New CNC difference adjusting system for rotary die cutting, Adjusting the error and difference of die-cutter's Cardboard, Easy operation Anvil roller and mould roller adopts high-grade steel with finely reground and chrome plated surface. Dynamic balancing correction enhances running stability Mould roller and anvil roller can be apart by the air cylinder eccentric mechanism , to decrease the load of the machine and to prolong the life of the cutting mould and urethane rubber Mechanical drive anvil roller transverse moves up to ±30mm, and installed with radial differential device, to improve the life of anvil roller Unique speed difference compensation device makes the anvil roller slide together to make a perfect die cutting Stack ing Unit Connection arm has manual and automatic operation methods Tension of the driving belt of connection arm can be adjusted alone; quantity of connection arms can be set at will Platform elevation and transmission motor has braking function, A pneumatic controlled plate, Anti slipping belt used in the transport bed lx307

Planetary gear phasing structure Printing phase automatic 360 degree adjust by PLC, touch screen and motorized digital control. Forme roller intelligent zero returning, short cut resetting under dynamic and static condition Motorized adjusts digital display the transversal position of the forme roller, up to 20 mm Slotting Machine Unit Pre-scoring wheel: Pre-scored paperboard will not crush Upper scoring wheel coated by polyurethane to avoid possible crush on the paperboard Transverse movement of scoring wheel, doctor wheel and slotting head controlled by motorized button control, lx308easy and quick 7 mm thick slotting knives are made of alloy tool steel by heat treatment and finely ground, sharpened endurable teeth Aluminium hand hole punch device. Die Cutting Unit New CNC difference adjusting system for rotary die cutting, Adjusting the error and difference of die-cutter's Cardboard, Easy operation Anvil roller and mould roller adopts high-grade steel with finely reground and chrome plated surface. Dynamic balancing correction enhances running stability Mould roller and anvil roller can be apart by the air cylinder eccentric mechanism , to decrease the load of the machine and to prolong the life of the cutting mould and urethane rubber Mechanical drive anvil roller transverse moves up to ±30mm, and installed with radial differential device, to improve the life of anvil roller Unique speed difference compensation device makes the anvil roller slide together to make a perfect die cutting Stack ing Unit Connection arm has manual and automatic operation methods Tension of the driving belt of connection arm can be adjusted alone; quantity of connection arms can be set at will Platform elevation and transmission motor has braking function, A pneumatic controlled plate, Anti slipping belt used in the transport bed lx307

*Subject to change and improvement without notice,

20140620*55555......

20140620*55555......

2.Memory 9999 orders

3.CNC adjusting system for die cutter

4.Flexo printing

LX308N Automatic Flexo Printing Slotting and Die Cutting Machine automatic carton box machine Main functions: Remote after service could be realized; Touch screen and electric control dual system lx308 All transmission gears are made of high quality alloy steel (20CrMnTi) grinded under high temperature with hardness HRC58-62 CAPT-LOCKS union link to reduce the connect interval and keep long lasting overprint precision Functions of intelligent zero returning and memory reset 9999 order memory The transmission system adopts two oil pumps circulating lubrication With new NC Adjusting System for die cutter ; Slotter with Intelligent photoelectric lx308n. E flute type cardboard could be used for printing carton; Suitable for small and middl-big size carton and many order change Better machine better carton, so as to Better business. Pizza box making machine price and corrugated box making line machine price are best and high quality. We provide loan to below business situation

1. The value of order over RMB 1 million (including 1 million).

2. Only for box machine LX308N; LX608CN; LX707N or corrugated machine production line include LXC-180NN, LXC-220H1.8N models.

3. We accept O/A (Open account), it based on the credit level of buyer's bank credit report. lx308n

4. The details please consult with our sales department. Feeding Unit Servo control Lead edge feeder--patent #ZL2005 2 0045628.x (Back-pushing suck blower feeding system is option);

Servo motor-quick react, lx308precision positioning, system stability and durability. Electrical camshaft supersedes mechanical style; Synchronous belt un-interval links feeding shaft with servo motor shaft, to improve feeding precision alignment; Half-wheel, quick replacing structure, to keep consistency of feeding position, and to avoid uneven wearing on the surface of feeding wheel; Pressure-free stretching feeding mechanism is the option; lx208n Printing Unit Box machine forme roller and pressure roller are made of high quality steel, with grinded and chrome plated surface, Dynamic and static balancing make steadily running, Hanging forme, make installation easy and quick, Forme changing both foot switch, and/or electric control (forward / backward run), Anilox roller auto lifting device synchronous working with paper feeding system (In feeding, anilox roller pressed whereas in stop, it released)

Servo motor-quick react, lx308precision positioning, system stability and durability. Electrical camshaft supersedes mechanical style; Synchronous belt un-interval links feeding shaft with servo motor shaft, to improve feeding precision alignment; Half-wheel, quick replacing structure, to keep consistency of feeding position, and to avoid uneven wearing on the surface of feeding wheel; Pressure-free stretching feeding mechanism is the option; lx208n Printing Unit Box machine forme roller and pressure roller are made of high quality steel, with grinded and chrome plated surface, Dynamic and static balancing make steadily running, Hanging forme, make installation easy and quick, Forme changing both foot switch, and/or electric control (forward / backward run), Anilox roller auto lifting device synchronous working with paper feeding system (In feeding, anilox roller pressed whereas in stop, it released)

Planetary gear phasing structure Printing phase automatic 360 degree adjust by PLC, touch screen and motorized digital control. Forme roller intelligent zero returning, short cut resetting under dynamic and static condition Motorized adjusts digital display the transversal position of the forme roller, up to 20 mm Slotting Machine Unit Pre-scoring wheel: Pre-scored paperboard will not crush Upper scoring wheel coated by polyurethane to avoid possible crush on the paperboard Transverse movement of scoring wheel, doctor wheel and slotting head controlled by motorized button control, lx308easy and quick 7 mm thick slotting knives are made of alloy tool steel by heat treatment and finely ground, sharpened endurable teeth Aluminium hand hole punch device. Die Cutting Unit New CNC difference adjusting system for rotary die cutting, Adjusting the error and difference of die-cutter's Cardboard, Easy operation Anvil roller and mould roller adopts high-grade steel with finely reground and chrome plated surface. Dynamic balancing correction enhances running stability Mould roller and anvil roller can be apart by the air cylinder eccentric mechanism , to decrease the load of the machine and to prolong the life of the cutting mould and urethane rubber Mechanical drive anvil roller transverse moves up to ±30mm, and installed with radial differential device, to improve the life of anvil roller Unique speed difference compensation device makes the anvil roller slide together to make a perfect die cutting Stack ing Unit Connection arm has manual and automatic operation methods Tension of the driving belt of connection arm can be adjusted alone; quantity of connection arms can be set at will Platform elevation and transmission motor has braking function, A pneumatic controlled plate, Anti slipping belt used in the transport bed lx307

Planetary gear phasing structure Printing phase automatic 360 degree adjust by PLC, touch screen and motorized digital control. Forme roller intelligent zero returning, short cut resetting under dynamic and static condition Motorized adjusts digital display the transversal position of the forme roller, up to 20 mm Slotting Machine Unit Pre-scoring wheel: Pre-scored paperboard will not crush Upper scoring wheel coated by polyurethane to avoid possible crush on the paperboard Transverse movement of scoring wheel, doctor wheel and slotting head controlled by motorized button control, lx308easy and quick 7 mm thick slotting knives are made of alloy tool steel by heat treatment and finely ground, sharpened endurable teeth Aluminium hand hole punch device. Die Cutting Unit New CNC difference adjusting system for rotary die cutting, Adjusting the error and difference of die-cutter's Cardboard, Easy operation Anvil roller and mould roller adopts high-grade steel with finely reground and chrome plated surface. Dynamic balancing correction enhances running stability Mould roller and anvil roller can be apart by the air cylinder eccentric mechanism , to decrease the load of the machine and to prolong the life of the cutting mould and urethane rubber Mechanical drive anvil roller transverse moves up to ±30mm, and installed with radial differential device, to improve the life of anvil roller Unique speed difference compensation device makes the anvil roller slide together to make a perfect die cutting Stack ing Unit Connection arm has manual and automatic operation methods Tension of the driving belt of connection arm can be adjusted alone; quantity of connection arms can be set at will Platform elevation and transmission motor has braking function, A pneumatic controlled plate, Anti slipping belt used in the transport bed lx307 Model | 1800/2200x1000 | 2500x1200/1400/1600 | 2800x1200/1400/1600 | |

Max. machine speed (pcs/min) | 200 | 160/140/120 | 160/140/120 | |

Max. printing speed(pcs/min) | 180 | 120 | 120 | |

Max. feeding size(mm) | 1770/2170*970 | 2500*1170/1370 | 2500*1170/1370 | |

Skip feeding size(mm) | 1770/2170*1170 | 2500*1370/1570/1770 | 2500*1370/1570/1770 | |

Min. feeding Size(mm) | 650*280 | 650*380/400/450 | 700*380/400/450 | |

Feeding depth (mm) | 2.5-10 | 2.5-10 | 2.5 - 10 | |

Min. slot interval | Positive cut (mm) | 120*120*120*120 | 140*140*140*140 | 140*140*140*140 |

| Reverse cut (mm) | 190*50*190*50 | 250*80*250*80 | 250*80*250*80

| |

Max. printing area(mm) | 1750/2150*950 | 2450*1150/1350 | 2750*1150/1350 | |

Standard printing plate thickness(mm) | 7.2 | 7.2 | 7.2 | |

20140620*55555......

20140620*55555...... Send your inquiry to this supplier

Send Inquiry