1 / 5

Garden Flower Pot Plastic Injection Moulds

| Model No. : | CT-10765 |

|---|---|

| Brand Name : | Ceeto |

| place of origin : | China |

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Product description

Nursery Garden Flower Pot Plastic Injection Mould belongs to Thin Wall Plastic Injection Mould, it produce round shape flower pot, this flower plant pots are ideal for keeping plants and flowers beautifully in your home or garden. It is made of hard plastic polypropylene material and round shaped design. It has pre-marked holes in the bottom position to drill out for water drainage if necessary. Flower pot plastic injection mould is required single cavity hot runner system for better filling if you are using new plastic PP not recycled PP for mass injection.

Flower Pot Plastic Product Description

Diameter Top of the Pot= 24.80cm

Diameter Bottom of the Pot= 14.21cm

Height of the Pot= 15.00cm

Main Wall thickness: 0.8mm

Flower Pot Plastic Injection Mould Description

- Mould cavity: single cavity

- Mould cavity and core steel: H13 is preferred

- Hardness for steel: 38-42 HRC

-

Injection material: PP (new material ), recycled PP is also acceptable and cold runner is the first option to use.

- Mould base: LKM

- Hot runner system: Yudo, Synventive, HRS etc.

- Suggested injection machine: 220T

- Ejection system: by stripper plate

- Leadtime: 40 days

-

Packing for mould: Wooden box

We are able to design and manufacture flow pot injection mould as per your 2D drawing and 3D model of flower pot, we supply you DFM report and moldflow analysis report, we have a strong design engineers team who are capable of providing you the perfect flower pot injection mould perfect design according to shrinkage rate, your injection machine technical data. Mould making refers to rough cutting, fine CNC high speed milling, EDM( Electrical Discharge Machining ), WEDM, water line drilling, mould bed-out via spotting machine and mould assembly fitting by bench works.

Quality Control to Flower Pot Plastic Mould

- Mould steel inspection ( Steel block surface defects inspection, and steel hardness inspection, request steel supplier to supply steel certification )

- Mould CMM measuring inspection ( Critical dimensions matched with products )

-

Plastic sample parts measuring inspection by CMM equipment and Callipers

-

All full dimensions reports will be shared to you for reviewing

- All "NG" dimensions will be double checked again and discussing with you about solutions to improve mould

- Mould dismantle and assembly inspection ( mainly checking mould components if they are broken during mould tests )

-

Mould standard components checking and mould apparence inspection before mould shipment

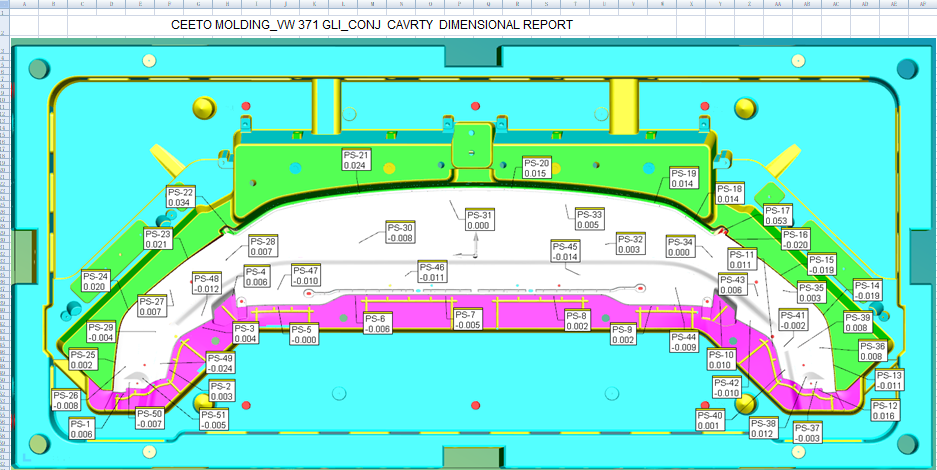

Here is an example of mould CMM report for cavity:

FAQ:

Q1: How long does a quotation take?

A1: In most cases, we respond within a couple of days of receiving an RFQ. However, there may be situations when we must source material from an external supply and therefore the quotation may be delayed accordingly.

Q2: What is the difference between a multi-cavity mold and a family mold?

A2: A multi-cavity mold has multiple cavities of the same part; a family mold produces a set. For instance, for an electronic enclosure, you may need a front, back, battery door, and a button. Those could all be molded at once in a family mold.

Q3: How long does it take to build a round shape flower pot injection mold?

A3: It's about 40 days for buying mould steel blocks to the first mould tryout, it means that 40 days from mould design approval to the first shot.

Q4: Can I modify the mold after the first run?

A4: We can modify our steel molds by additional machining, fill-in welding, welding in additional material, or inserting a replacement feature, for a reasonable cost. If the changes are too great, however, producing a new mold may be more cost-effective than reworking the existing one.

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier