1 / 1

Galvanized Steel Trapezoid Roof Sheet Forming Machine

| Model No. : | SUF |

|---|---|

| Brand Name : | SUF |

| Forming Speed : | 10-15m/min |

Shijiazhuang, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Product description

Galvanized Steel Trapezoid Roof Sheet Forming Machine

Trapezoid Roof Sheet Roll Forming Machine is different from other productions. Steel Trapezoid Roll Forming Machine uses new technology. Galvanized Roof Sheet Forming Machines are widely used in building. What's more, our Galvanized Steel Trapezoid Roof Sheet Forming Machine equipment can be designed and manufactured as customers' requests.

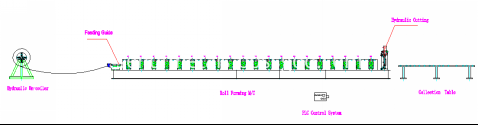

Working Flow:

Decoiler - Feeding Guide - Main Roll Forming Machine - PLC Contol System - Hydraulic Cutting - Output Table

Components:

5 Tons Hydraulic Decoiler

Leveling

Main Roll Forming

Hydraulic station

PLC Control system

Hydraulic cutting

Receving table

Technical parameters:

1. Raw materials: Galvanized coils, Pre-painted coils, Aluminum coils

2. Material thickness range: 0.2-1mm

3. Forming speed: 10-15m/min

4. Rollers: 15 rows(according to drawings)

5. Material of rollers: 45# steel with chromed

6. Shaft material and diameter: 76mm, material is 45#

7. Material of body: 400H steel

8. Wall panel: 20mm Q195 steel(all with electrostatic spraying)

9. Controlling system: PLC

10. Main power: 5.5KW/7.5KW

11. Material of cutting blade: Cr12 mould steel with quenched treatment

12. Voltage: 380V/3Phase/50Hz(according to customers')

13. Total weight: about 5 tons

5 Tons Hydraulic Decoilers:

Inner Diameter: 450-600mm

Outer Diameter: 1500mmCoil Width: 1300mm

Leveling:

Keep materials straight, and the width can be adjusted by manual.

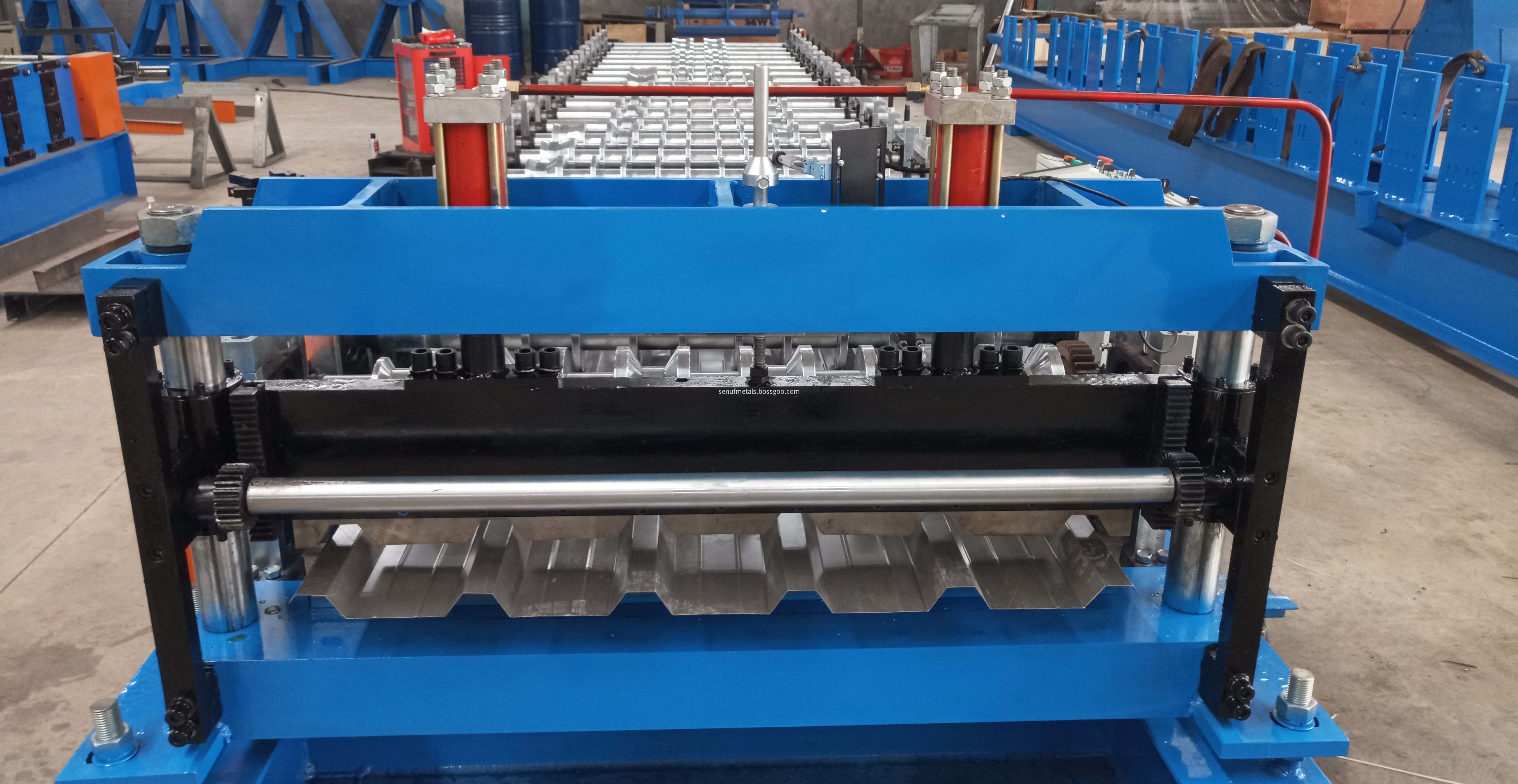

Main Roll Forming:

1. Machine frame: 400H Steel

2. Transmission: Chain

3. Forming steps: 16-20 steps

4. Shaft Diameter: 75mm

5. Roller Material: 45# steel with chromed

6. Forming Speed: 10-15m/min

7. Motor: 7.5KW

Hydraulic station:

1. Power of the oil pump: 4kw

2. Hydraulic oil :40#

Control System: PLC

Brand: Delta

Language: Chinese and English (as required)

Function: Automatic control the cutting length and quantity, easy to operate and use.

Hydraulic cutting:

Cutter Material: Cr12 mould steel with quenched treatment

Cutting Tolerance: ±1.5mm

Shijiazhuang, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier