1 / 5

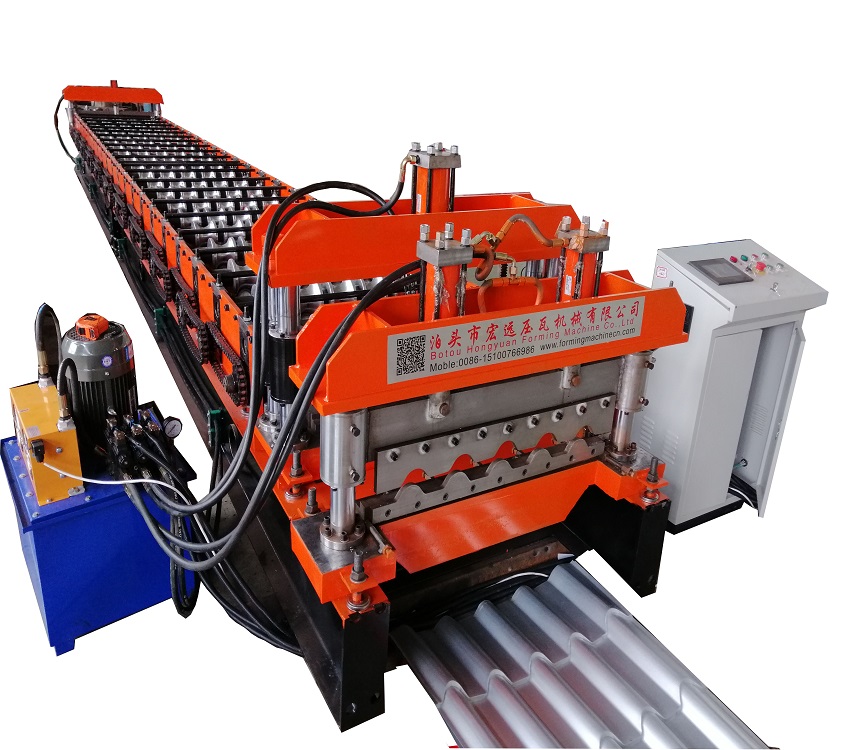

Galvanized steel sheet glazed tile machine

| Model No. : | Glazed tile machine |

|---|---|

| Brand Name : | Hongyuan |

| Warranty : | 1 Year |

Product description

Galvanized steel sheet glazed tile machine

Machine Parameters :

Glazed Tile Roll Forming Machine

Coil Material

Type

Colored Steel Plate, Galvanized Board, Aluminum Plate

Width

1200mm/1220mm/1250mm according to the profile drawing

Thickness

0.25-0.6mm

Manual Decoiler

Inside diameter

500-508mm

Coil width

1300mm

Coil load

5T

Forming Device

Shaft Material

45# steel,Φ70mm solid shaft

Roller Material

45# steel with chrome coating

Roller Station

22rows based on final profile

Main Frame

300H steel

Board Thickness

16mm

Chain Transport

1 inch

Weight

About 3tons

Dimension

7500mm*1500mm*1300mm (according to the final profile drawing)

Control System

PLC control system

Total Motor

5.5kw+4kw(depend on the final profile drawing)

Productivity

3-4m/min

Voltage

380V,50HZ,3phase (or as your need)

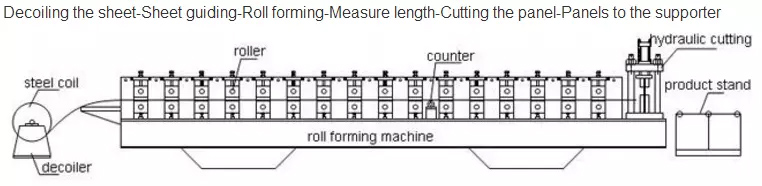

Working Flow:

Glazed Tile Roll Forming Machine Details :

1.Cutting System

Material of blade:Cr12Mov which has high strength and durable quality.

It can cut suitable panel length according to the oil pump and PLC control system

2.Roller System

Material of roller:#45 hard chrome plating steel

Roller stations:22 rows ,or as final drawing

Thickness:0.3-0.8 mm

3.Computer Control Cabinet

Programmable setting of profile Length and quantity.

Computer mode has two modes:automatic and manual one

Language:according to client's require

4.Feeding Table

It used to control the width and position of the steel sheet.

The sheet is guided into the machine with correct position,to make sure the sheet is neat and parallel.

5.Decoiler

Loading capacity:3 ,5,7,10tons

Inner diamater:450-508 mm

Type:Manual decoiler and auto decoiler

Company Profile

a. Two decades professional cold steel forming equipments manufacturer

Main products: glazed tile roll forming machine, ridge cap roll forming machine, corrugated roll forming machine, most popular color steel roll forming machine, double deck color steel roll forming machine, keel roll forming machine, C/Z purlin forming machine, Austalia style roller shutter door forming machine and etc.

b. National GB/T, CE and ISO9001:2008 standard

c. Business relationship with customers from more than 30 countries and areas

Packaging Details:

1. one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

FAQ:

A:- What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, etc. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- About the after-sales service. We can send technician to your country to fix the machine. The buyer should bear all the cost including: visa, Round trip ticket and suitable accommodation, also buyer should pay the salary 80USD/day.

The warranty is one year. and we will provide the technical support for the whole life. It is free to maintain the machine the first year after buying, including changing the main components. The first year hence, you will pay for our technician $50 per day to maintain the machine. And the components are not free, if you need to get it from us.

E:- Any other service?

- We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

Send your inquiry to this supplier