1 / 2

galvanized pipe machine/high frequency tube mill

Get Latest Price

Send Inquiry

| Model No. : | ZY |

|---|---|

| Brand Name : | ZY |

Cangzhou Zhiye Cold Forming Machinery Co., Ltd.

You might also like

Product description

Specifications galvanized pipe machine/high frequency tube mill

1.high speed

2.round,square,on one machine,different sizes

3.stable running

galvanized pipe machine/high frequency tube mill Product Description Abstract of the galvanized pipe machine/high frequency tube mill : high-frequency Welding Pipe Cold Roll Forming Machine is designed to produce welded round pipes of Φ30~Φ52mm in diameter and 2.9~3.9mm in wall thickness, as well as square (Optional),rectangular pipes and formed sections of the corresponding size. The products conform to BS/ASTM Standard. Adopting the advantages of the equipment of the same kind at home and abroad, each element of the production line is designed with new ideas of best quality as well as performance with lowest possible consumption of energy. The application of the PLC / automatic control system and British Euro therm digital speed regulating unit guarantee that the production line works reliably and operates and maintains easily. Features of this galvanized pipe machine/high frequency tube mill lower cost high efficiency reliable working low energy consumption Components of the galvanized pipe machine/high frequency tube mill Semi-auto shear welder Cage accumulator Forming & sizing mill STD flying saw H.F welder Optional components of the galvanized pipe machine/high frequency tube mill ·Manual uncoiler frame in different tons ·Hydraulic automatic uncoiler Working space and workman for the galvanized pipe machine/high frequency tube mill : 1. Ground-level land 2. ≥5T overhead travelling crane 3. Space for storing the material 4. Space for laying the machine 5. Road for vehicle moving 6. Workman: 2, operator and porter Picture for some parts of the galvanized pipe machine/high frequency tube mill for references Packaging & Shipping Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

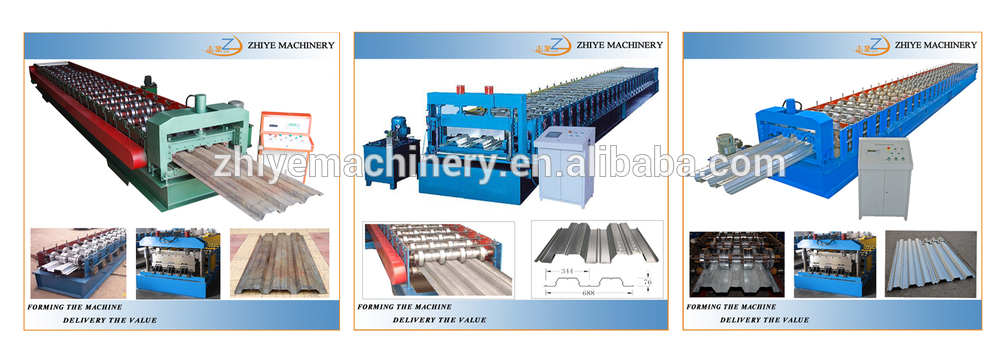

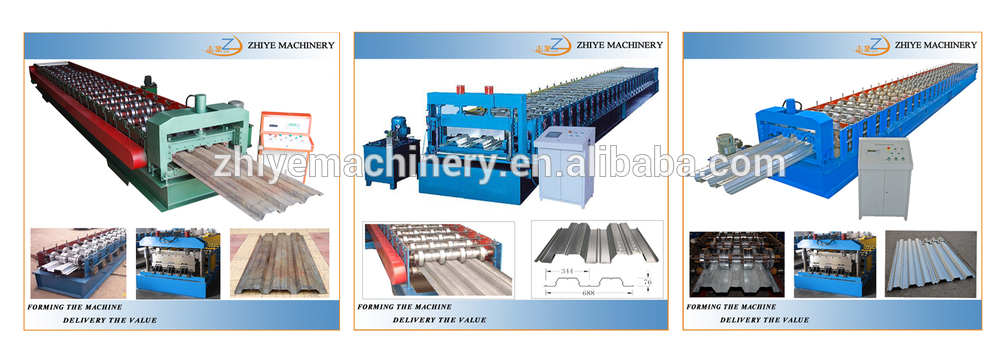

Packaging & Shipping Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.  Our Services We will offer technical support for all the roll forming machines the whole life. 2 years free spare parts replacement and maintaince. Our international technicians can be reach your workshop at the first time if your machines has problem. Company Information Cangzhou Zhiye Cold Forming Machinery Co., Ltd is the manufacturer specialized in various cold forming machineries and automatic production lines. Main products are: roofing/wall panel roll forming machines, tile roll forming machines, C/U/Z purlin roll forming machines, floor decking roll forming machines, steel frame truss roll forming machines, pipe roll forming machines and customerized machines. Our main roll forming machines are: Roofing sheet roll forming machine

Our Services We will offer technical support for all the roll forming machines the whole life. 2 years free spare parts replacement and maintaince. Our international technicians can be reach your workshop at the first time if your machines has problem. Company Information Cangzhou Zhiye Cold Forming Machinery Co., Ltd is the manufacturer specialized in various cold forming machineries and automatic production lines. Main products are: roofing/wall panel roll forming machines, tile roll forming machines, C/U/Z purlin roll forming machines, floor decking roll forming machines, steel frame truss roll forming machines, pipe roll forming machines and customerized machines. Our main roll forming machines are: Roofing sheet roll forming machine  Glazed tile roll forming line

Glazed tile roll forming line  Floor decking panel making machines

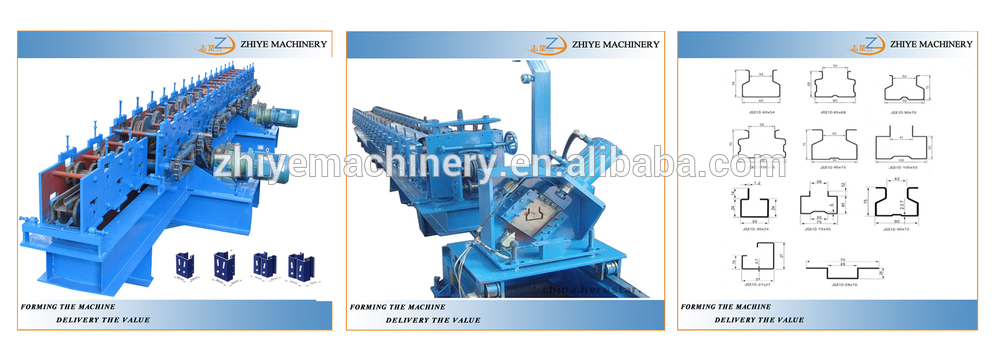

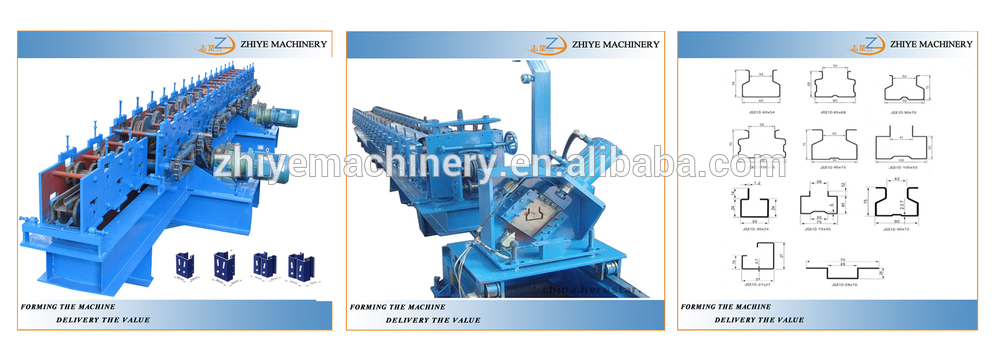

Floor decking panel making machines  CUZ purlin production line

CUZ purlin production line  Roller shutter door manufacturer machinery

Roller shutter door manufacturer machinery  Steel truss frame rolling forming equipments

Steel truss frame rolling forming equipments  Downspout cold forming machines

Downspout cold forming machines  Barrel corrugated cold forming line

Barrel corrugated cold forming line  Sandwich panel cold production line

Sandwich panel cold production line  Shelf rack cold roll forming machinery

Shelf rack cold roll forming machinery  Pipe/tube mill roll forming machine

Pipe/tube mill roll forming machine  For further information, welcome to contact at: James LEE SKYPE: rollformingmachines Mob:+86 157 3274 8855 Sincerely wish to estabilish win-win business relationship with you!

For further information, welcome to contact at: James LEE SKYPE: rollformingmachines Mob:+86 157 3274 8855 Sincerely wish to estabilish win-win business relationship with you!

1.high speed

2.round,square,on one machine,different sizes

3.stable running

galvanized pipe machine/high frequency tube mill Product Description Abstract of the galvanized pipe machine/high frequency tube mill : high-frequency Welding Pipe Cold Roll Forming Machine is designed to produce welded round pipes of Φ30~Φ52mm in diameter and 2.9~3.9mm in wall thickness, as well as square (Optional),rectangular pipes and formed sections of the corresponding size. The products conform to BS/ASTM Standard. Adopting the advantages of the equipment of the same kind at home and abroad, each element of the production line is designed with new ideas of best quality as well as performance with lowest possible consumption of energy. The application of the PLC / automatic control system and British Euro therm digital speed regulating unit guarantee that the production line works reliably and operates and maintains easily. Features of this galvanized pipe machine/high frequency tube mill lower cost high efficiency reliable working low energy consumption Components of the galvanized pipe machine/high frequency tube mill Semi-auto shear welder Cage accumulator Forming & sizing mill STD flying saw H.F welder Optional components of the galvanized pipe machine/high frequency tube mill ·Manual uncoiler frame in different tons ·Hydraulic automatic uncoiler Working space and workman for the galvanized pipe machine/high frequency tube mill : 1. Ground-level land 2. ≥5T overhead travelling crane 3. Space for storing the material 4. Space for laying the machine 5. Road for vehicle moving 6. Workman: 2, operator and porter Picture for some parts of the galvanized pipe machine/high frequency tube mill for references

Packaging & Shipping Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

Packaging & Shipping Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.  Our Services We will offer technical support for all the roll forming machines the whole life. 2 years free spare parts replacement and maintaince. Our international technicians can be reach your workshop at the first time if your machines has problem. Company Information Cangzhou Zhiye Cold Forming Machinery Co., Ltd is the manufacturer specialized in various cold forming machineries and automatic production lines. Main products are: roofing/wall panel roll forming machines, tile roll forming machines, C/U/Z purlin roll forming machines, floor decking roll forming machines, steel frame truss roll forming machines, pipe roll forming machines and customerized machines. Our main roll forming machines are: Roofing sheet roll forming machine

Our Services We will offer technical support for all the roll forming machines the whole life. 2 years free spare parts replacement and maintaince. Our international technicians can be reach your workshop at the first time if your machines has problem. Company Information Cangzhou Zhiye Cold Forming Machinery Co., Ltd is the manufacturer specialized in various cold forming machineries and automatic production lines. Main products are: roofing/wall panel roll forming machines, tile roll forming machines, C/U/Z purlin roll forming machines, floor decking roll forming machines, steel frame truss roll forming machines, pipe roll forming machines and customerized machines. Our main roll forming machines are: Roofing sheet roll forming machine  Glazed tile roll forming line

Glazed tile roll forming line  Floor decking panel making machines

Floor decking panel making machines  CUZ purlin production line

CUZ purlin production line  Roller shutter door manufacturer machinery

Roller shutter door manufacturer machinery  Steel truss frame rolling forming equipments

Steel truss frame rolling forming equipments  Downspout cold forming machines

Downspout cold forming machines  Barrel corrugated cold forming line

Barrel corrugated cold forming line  Sandwich panel cold production line

Sandwich panel cold production line  Shelf rack cold roll forming machinery

Shelf rack cold roll forming machinery  Pipe/tube mill roll forming machine

Pipe/tube mill roll forming machine  For further information, welcome to contact at: James LEE SKYPE: rollformingmachines Mob:+86 157 3274 8855 Sincerely wish to estabilish win-win business relationship with you!

For further information, welcome to contact at: James LEE SKYPE: rollformingmachines Mob:+86 157 3274 8855 Sincerely wish to estabilish win-win business relationship with you! Send your inquiry to this supplier

Send Inquiry