Video

1 / 4

Furniture Quality Control and Inspection Service in Shandong

Zhengzhou, Henan, China

- Service

- Trade Company

- Gold Supplier

- Platform Certification

Product description

This is a detailed visual and technical Inspection of goods before the shipment.

If the production is finished, or at least 80% of products are packed and ready for shipment the

samples are selected and tested randomly, according to AQL sampling standards and procedures.

It will be generally done in the manufacturer's premises and the samples selected according to defined sampling procedures.

The Inspection criteria are quality, quantity, marking and packing and are based on the client's demands and requirements.

Upon the completion of Pre Shipment Inspection, a detailed Report will be sent to the client.

|

- Appearance: |

Size, color, shape, processing, etc. |

|

- Function: |

Subject to the item inspected |

|

- Safety: |

Rough or sharp edg e, creep age, approvals (CE, GS, etc.) etc. |

|

- Transport: |

Drop test |

|

- Packing: |

Inner & outer, carton marks, etc. |

|

- General Test: |

Color wear, tension, pressure, burning point, etc. |

Pre-Production Inspection (PPI)

At the beginning of the production, a detail check of the quality and specification for components, materials, and accessories against clients' specifications will avoid further problems. The PPI allows a timely corrections and improvements before the goods will be mass production.

Any non-conformity will be immediately reported to avoid delay in shipment.

During production inspection (DUPRO)

A visual check on the quality of components, materials and finished products when at least 10-20% of the order has been completed production.

Randomly inspection of the finished goods in the production line to check for possible defects.

If any defects appear, a prompt action plan with corrective measurement will take place to fix the problems and ensure further production to match product standard.

In general, we will check the following aspects for DUPRO:

- Follow the flow of the materials in the production line.

- Analyze and evaluate the production status, finding of bottle necks and optimize the manufacturing process.

- Pick samples randomly of the finished goods and compare them with your product specififcations.

- Verify the packing details and packing material.

100% Inspection and Sorting

When the goods are 100% completed, we will check the quality of goods pcs by pcs.

This covers the product description, style & color, overall finish, quality, function, label, package, size measurement, etc., to make sure 100% of the goods meet your specified quality requirement.

All defects get sort out and will be stored separate.

Container Loading Inspection (CLI)

In general, we will check the following aspects for CLI:

- Record the weather condition and loading location.

- The arrival time of container with the Container and Truck No.

- Check the inner/outer condition of the container to see if there is any damage/wet/hole/peculiar smell

- Check the quantity of the goods to be loaded

- Record the condition of packaging (master cartons/pallets/drums)

- Pick randomly some samples and open some cartons to verify that the right goods are inside,

- Supervise and monitor the whole loading process

- Seal the container with the custom's seal and Container seal

- Record the seal No. and departure time of container.

All will be provided into a report with detail photo documentation.

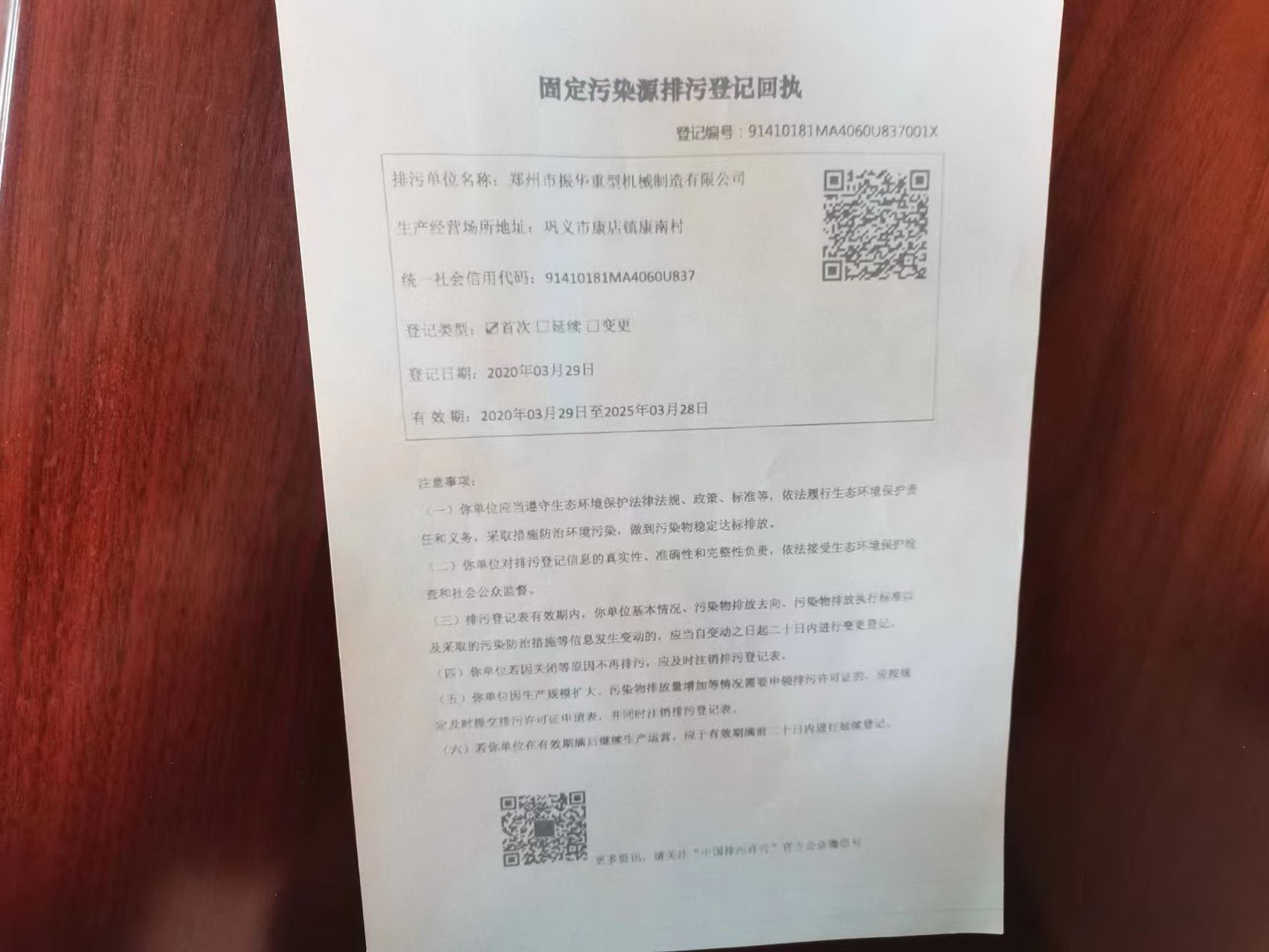

Factory Audit

Before starting a partnership with supplier, We will:

· Ensure that supplier work effectively and will examine the company in advance

· Check if the company is in reasonable condition

· Employees work according to your requirements

· Supplier can produce goods according to your requirements

In general, we will check:

· The company profile

· The organization chart and structure

· The production set up, process, work flow and organization

· Machinery, equipment, facilities

· The Quality Assurance Process, organization, system and certificate

· R&D department

Video

Zhengzhou, Henan, China

- Service

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier